Forming method of super-hybrid composite material special-shaped part

A composite material and molding method technology, which is applied to molding tools, feeding devices, manufacturing tools, etc., can solve the problems of high mold cost and low efficiency, and achieve good molding results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

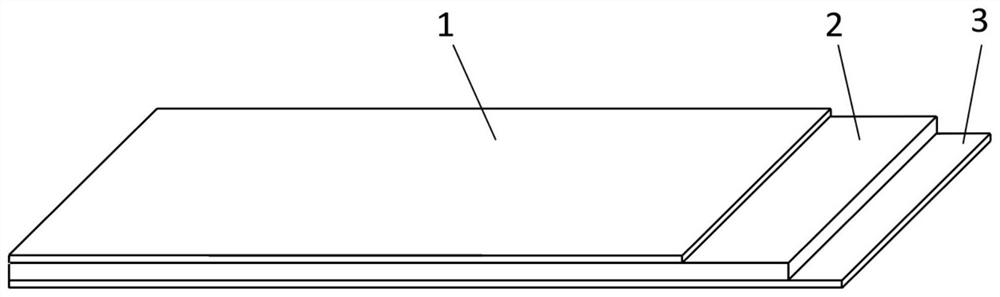

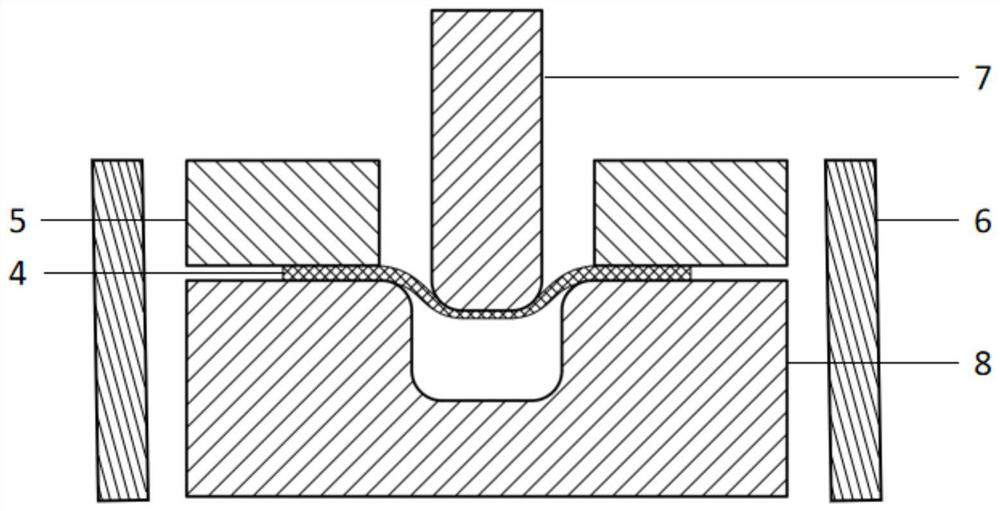

[0052] A method for forming a special-shaped part of a super-hybrid composite material, comprising the following steps:

[0053] S1. According to the required shape of the cup convex special-shaped parts, cut two pieces of 6061T6 aluminum alloy plates with a side length of 17cm, a thickness of 0.2mm and a surface that has been sandblasted, and cut 4 pieces of side length according to the layup design It is 17cm basalt fiber reinforced polypropylene prepreg unidirectional tape, and then according to [0° / 90° / 90° / 0°] layup method on an aluminum alloy plate, and then with another aluminum alloy plate , put it into the molding machine after being fixed, hold it for 2 minutes under the preset molding temperature of 200 °C and the preset molding pressure of 1 MPa, and then take it out to prepare a hyperhybrid composite laminate with a thickness of 2 mm. The hyperhybrid composite The laminated board was cut into a circle with a diameter of 16 cm according to the shape required for pun...

Embodiment 2

[0056] A method for forming a special-shaped part of a super-hybrid composite material, comprising the following steps:

[0057] S1. According to the required shape of the cup convex special-shaped parts, cut two pieces of 6061T6 aluminum alloy plates with a side length of 17cm, a thickness of 0.2mm and a surface that has been sandblasted, and cut 4 pieces of side length according to the layup design It is 17cm basalt fiber reinforced polypropylene prepreg unidirectional tape, and then it is laid up on one aluminum alloy plate according to the layup method of [-45° / 0° / 45° / 90°], and then it is laminated with another aluminum alloy plate After the plate is fixed, put it into the molding machine, hold it for 2 minutes under the preset molding temperature of 200 °C and the preset molding pressure of 1 MPa, and then take it out to prepare a hyperhybrid composite laminate with a thickness of 2 mm. The hyperhybrid composite The laminated board was cut into a circle with a diameter of...

Embodiment 3

[0060] A method for forming a special-shaped part of a super-hybrid composite material, comprising the following steps:

[0061] S1. According to the required shape of the cup-convex special-shaped parts, cut two 6061T6 aluminum alloy plates with a diameter of 17cm and a thickness of 0.2mm and the surface has been sandblasted. According to the layer design, cut 16 sheets with a central angle of 45 °, fan-shaped basalt fiber reinforced polypropylene unidirectional tape prepreg with a diameter of 8.5cm, and then follow each layer according to Figure 4a ~ Figure 4d Splicing in sequence, splicing 4 pieces of basalt fiber reinforced polypropylene unidirectional tape prepregs in different directions in the same layer, the unidirectional tapes in different directions in two adjacent layers form a certain angle, lay 4 layers, and then connect with the outer surface The two aluminum alloy plates were fixed and put into the molding machine. After the preset molding temperature was 200°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com