Preparation method of fullerene C60 derived electrocatalyst

An electrocatalyst, fullerene technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of good graphitization structure, good ORR performance, and high degree of disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

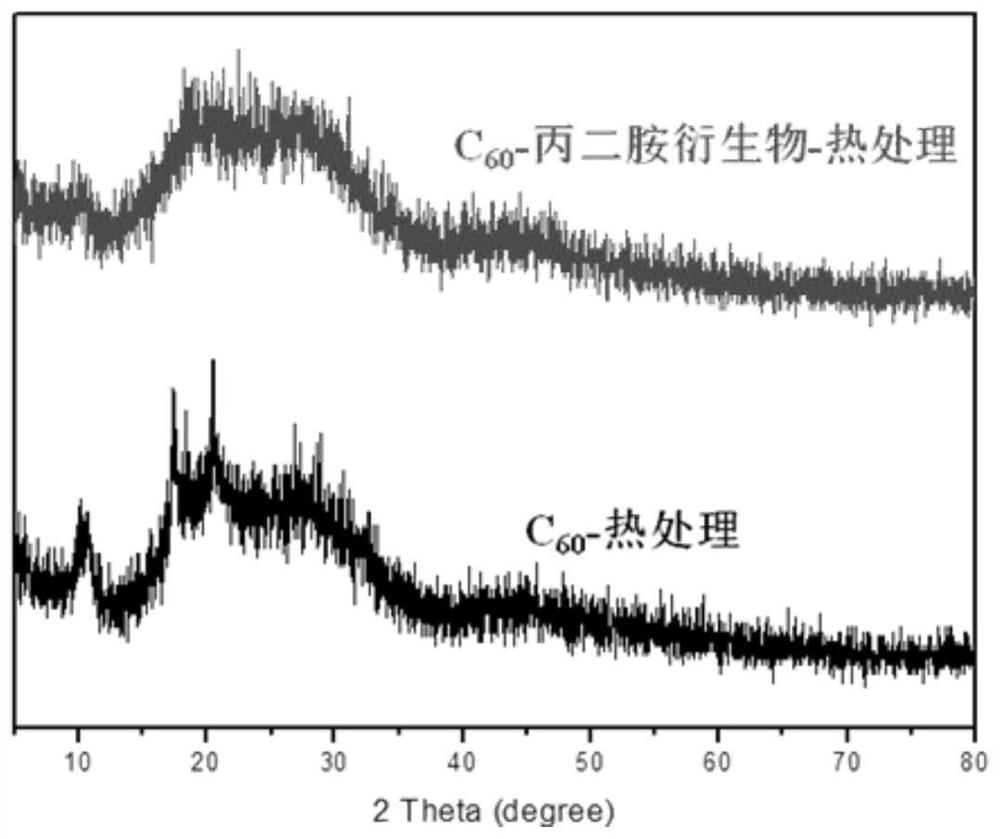

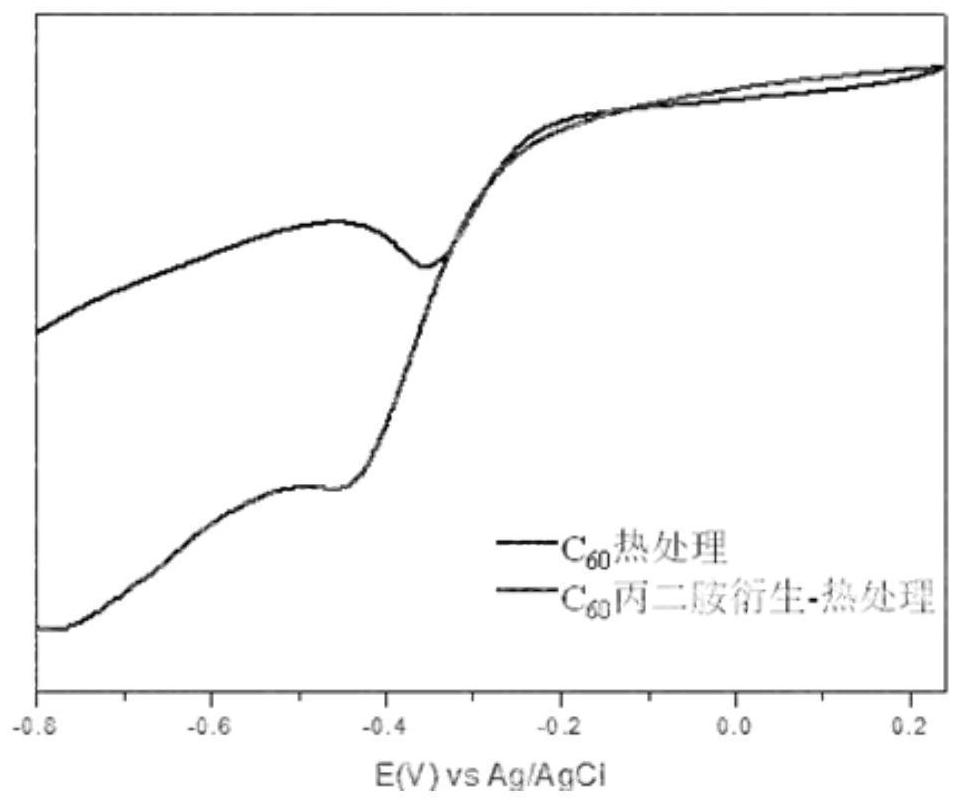

[0021] The present invention discloses a fullerene C 60 The preparation method of derivative electrocatalyst, preparation steps are as follows:

[0022] S1. Take 800.0mg fullerene C 60 Dissolve in 300.0mL p-xylene, stir well to make fullerene C 60 After dissolving, add 30mL propylenediamine to the solution, then use a magnetic stirrer to stir the above mixture at room temperature until the fullerene C 60 Till the dark purple fades;

[0023] S2. Use a glass rod to drain the magnetically stirred mixed solution into a separatory funnel, let it stand for stratification, and collect the lower suspension with a beaker;

[0024] S3. Wash the suspension once with 0.1mol / L hydrochloric acid solution, pour the washed suspension into a centrifuge tube for centrifugation at a speed of 10000r / min, and centrifuge for 10min. After centrifugation, wash with deionized water until suspension The solution is neutral, and then put the centrifuged and washed solid into a vacuum drying oven for...

Embodiment 1

[0027] 1) Fullerene C reacted with organic base 60 Derivatives Preparation

[0028] Take 800.0mg fullerene C 60 Dissolve in 300.0mL p-xylene, stir well with a stirring bar to make fullerene C 60 Dissolve completely, then add 30mL propylenediamine to the solution, then use a magnetic stirrer to stir the above mixture at room temperature until the fullerene C 60 Till the dark purple fades;

[0029] Then use a glass rod to drain the magnetically stirred mixed solution into a separatory funnel, let it stand for stratification, and present the lower layer of suspension, the upper layer of colorless liquid, and the lower layer of suspension is the required sample liquid, which is collected with a beaker. During the collection process, the suspension in the lower layer flows down the wall of the beaker;

[0030] Then wash the suspension once with 0.1mol / L hydrochloric acid solution, pour the washed suspension into a centrifuge tube for centrifugation, the centrifugal speed is 100...

Embodiment 2

[0034] This embodiment prepares fullerene C 60 The steps of deriving the electrocatalyst are the same as in Example 1, but the heat treatment temperature of the vacuum tube furnace in this example is 300° C., and the heat treatment time is 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com