High-throughput rapid preparation method of three-dimensional flexible composite positive electrode material for seawater dissolved oxygen battery

A composite positive electrode material, three-dimensional flexible technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low discharge efficiency, long-term discharge, large volume, etc., and achieve uniform distribution, easy operation, and high energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

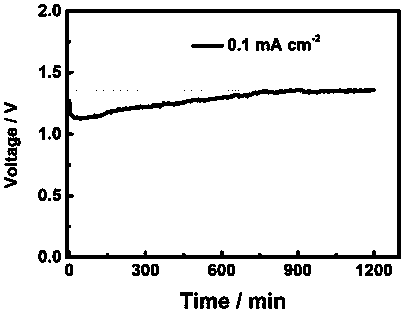

[0044] A high-throughput rapid preparation method of a three-dimensional flexible composite positive electrode material for a seawater dissolved oxygen battery of the present invention, the preparation process includes the following steps:

[0045] In this method, the carbon fiber is first cut and processed to form a three-dimensional spiral carbon fiber structure;

[0046] Then the three-dimensional helical carbon fiber structure is subjected to high-temperature heat treatment and ultrasonic treatment. The purpose of high-temperature heat treatment is to remove surface impurities and improve the activity of the material. The purpose of ultrasonic treatment is to ensure that the carbon fiber filaments are evenly dispersed;

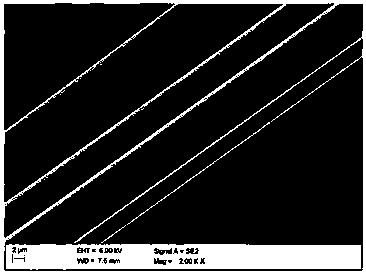

[0047]Then, the high-throughput electrochemical etching and stripping method is used to modify the three-dimensional helical carbon fiber structure to obtain a layered structure with a rough surface to ensure the rough stripped state of the carbon fiber fil...

Embodiment 1

[0050] A high-throughput rapid preparation method of a three-dimensional flexible composite cathode material for a seawater dissolved oxygen battery according to the present invention, the specific steps of the preparation process include the following:

[0051] 1. Three-dimensional spiral carbon fiber structure cutting and processing

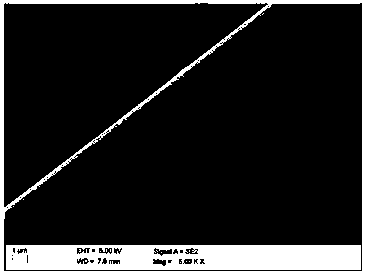

[0052] Cut the carbon fiber with a specification of 12k into a carbon fiber strip with a length of 3 cm, fix it evenly between two tight titanium alloy wires, and use a wire twister to rotate and twist the wire at a constant speed to obtain a carbon fiber strip with a diameter of about 3 cm and a handle length of 10 cm. Three-dimensional helical carbon fiber structure with a column height of 5 cm, see attached figure 1 .

[0053] 2. High temperature heat treatment of three-dimensional spiral carbon fiber structure

[0054] The processed carbon fiber structure was placed in a muffle furnace for high-temperature heat treatment. The temperature ...

Embodiment 2

[0061] A high-throughput rapid preparation method of a three-dimensional flexible composite cathode material for a seawater dissolved oxygen battery according to the present invention, the specific steps of the preparation process include the following:

[0062] 1. Three-dimensional spiral carbon fiber structure cutting and processing

[0063] Cut the carbon fiber with a specification of 12k into a carbon fiber strip with a length of 5 cm, and evenly fix it in the middle of two tight titanium alloy wires. Use a wire twister to rotate and twist the wire at a constant speed to obtain a carbon fiber column with a diameter of about 5 cm and a handle length of 15 cm. Three-dimensional helical carbon fiber structure with a height of 10 cm, see attached figure 1 .

[0064] 2. High temperature heat treatment of three-dimensional spiral carbon fiber structure

[0065] Place the processed carbon fiber structure in a muffle furnace for high-temperature heat treatment. The temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com