Composite material with electrocatalytic oxygen reduction performance, preparation method thereof and use thereof

A composite material, electrocatalytic oxygen technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems that hinder the promotion and application of fuel cells, high cost of fuel cells, loss of reducibility, etc., and achieve high-efficiency electrocatalytic oxygen reduction performance , low cost, and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

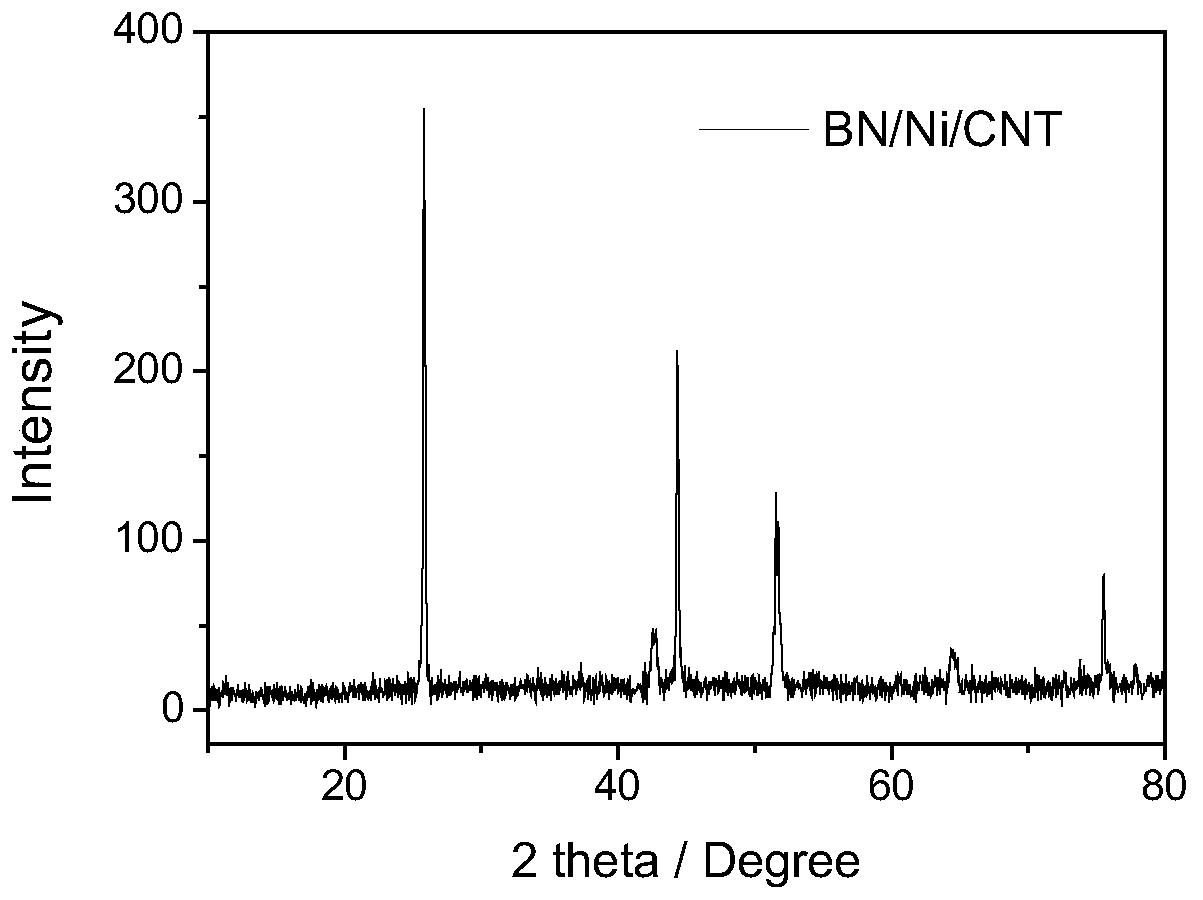

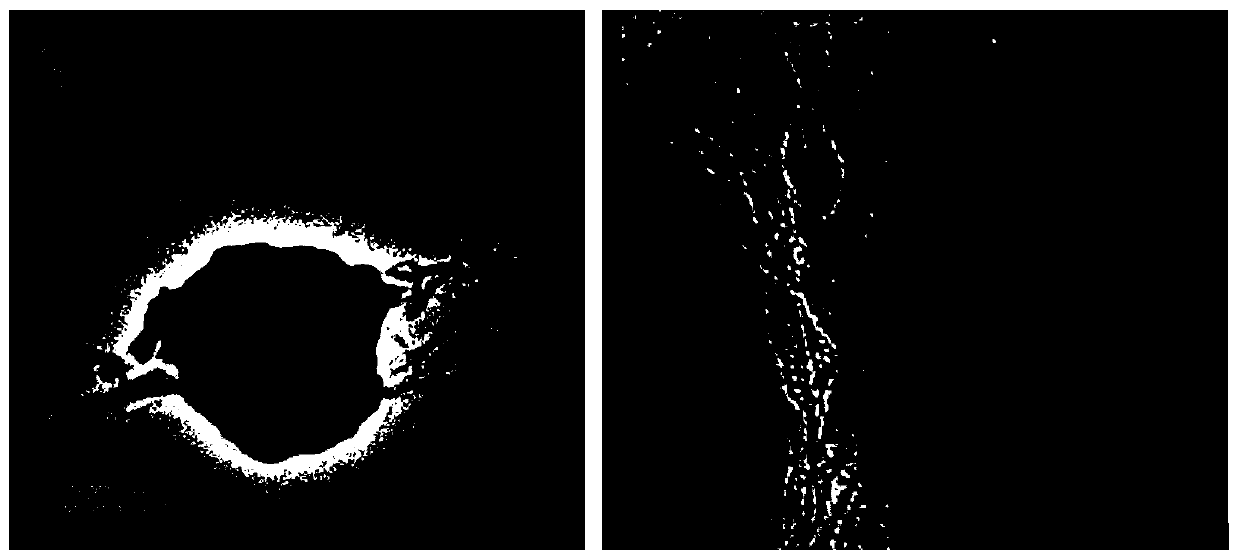

Embodiment 1

[0082] A BN / Ni / CNT composite material, in which metal Ni is evenly attached between BN sheets and on the surface of the sheets, and CNT fixes Ni and BN to form a spherical structure with a particle size of 100-300nm. Among them, the molar ratio of BN, Ni and CNT is 1:2:1.

[0083] Its preparation method comprises the following steps:

[0084] (1) Add 0.005mol carbon nanotube (CNT) and 0.005mol boron nitride (BN) into 50mL of ethylene glycol, and ultrasonically disperse for 30min;

[0085] (2) Add 0.01mol NiCl under stirring 2 ·6H 2 0, 0.06mol urea, continue to stir for 10min, fully dissolve the solid and make the solution mix uniformly;

[0086](3) After standing for 20 minutes, the reaction system was heated and refluxed for 6 hours. After the reaction, it was cooled to room temperature, and the solid was washed with double distilled water and ethanol, respectively, and washed 3 times respectively, wherein the speed of the centrifuge was 8000r / min. , and centrifuge for 5 ...

Embodiment 2

[0091] The preparation method of the BN / Ni / CNT composite material in this example is the same as that of Example 1, and the difference from Example 1 is that step (3) is heated under reflux for 8 hours. The structure of the obtained material is similar to Example 1.

Embodiment 3

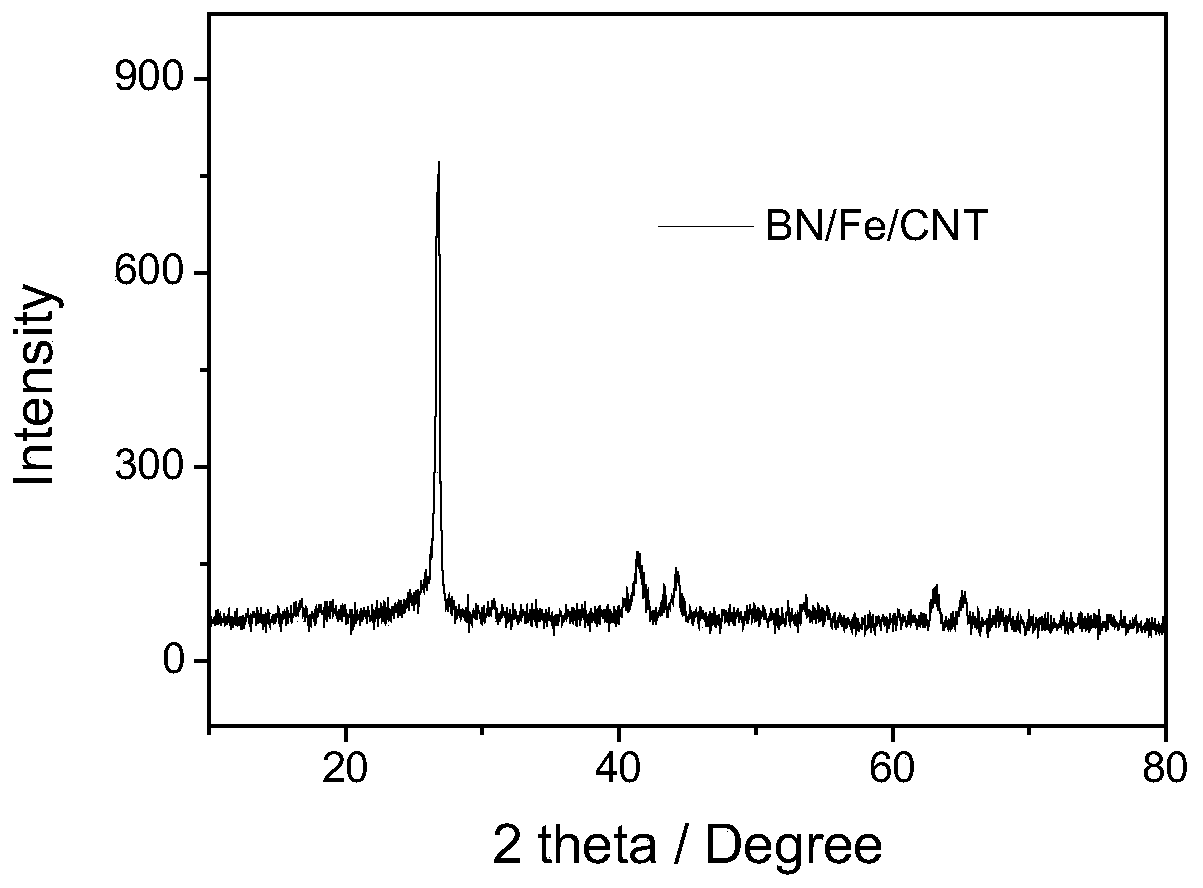

[0093] A BN / Fe / CNT composite material, in which metal Fe is evenly attached between BN sheets and on the surface of the sheets, and CNT fixes Fe and BN to form a spherical structure with a particle size of 100-300nm. Among them, the molar ratio of BN, Fe and CNT is 1:2:1. Its preparation method comprises the following steps:

[0094] (1) Add 0.005mol carbon nanotube (CNT) and 0.005mol boron nitride (BN) into 50mL of ethylene glycol, and ultrasonically disperse for 30min;

[0095] (2) Add 0.01mol FeCl under stirring 3 ·6H 2 0, 0.06mol urea, continue to stir for 10min, fully dissolve the solid and make the solution mix uniformly;

[0096] (3) After standing for 20 minutes, the reaction system was heated and refluxed for 6 hours. After the reaction, it was cooled to room temperature, and the solid was washed with double distilled water and ethanol, respectively, and washed 3 times respectively, wherein the speed of the centrifuge was 8000r / min. , and centrifuge for 5 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com