Preparation method and application of nitrogen-doped porous biomass carbon

A biomass carbon and nitrogen doping technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of complex preparation process, unsuitable for large-scale commercial application, etc., and achieve improved pore structure, stability and methanol resistance. The effect of improving the sex and increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing nitrogen-doped porous biomass carbon, comprising the following steps:

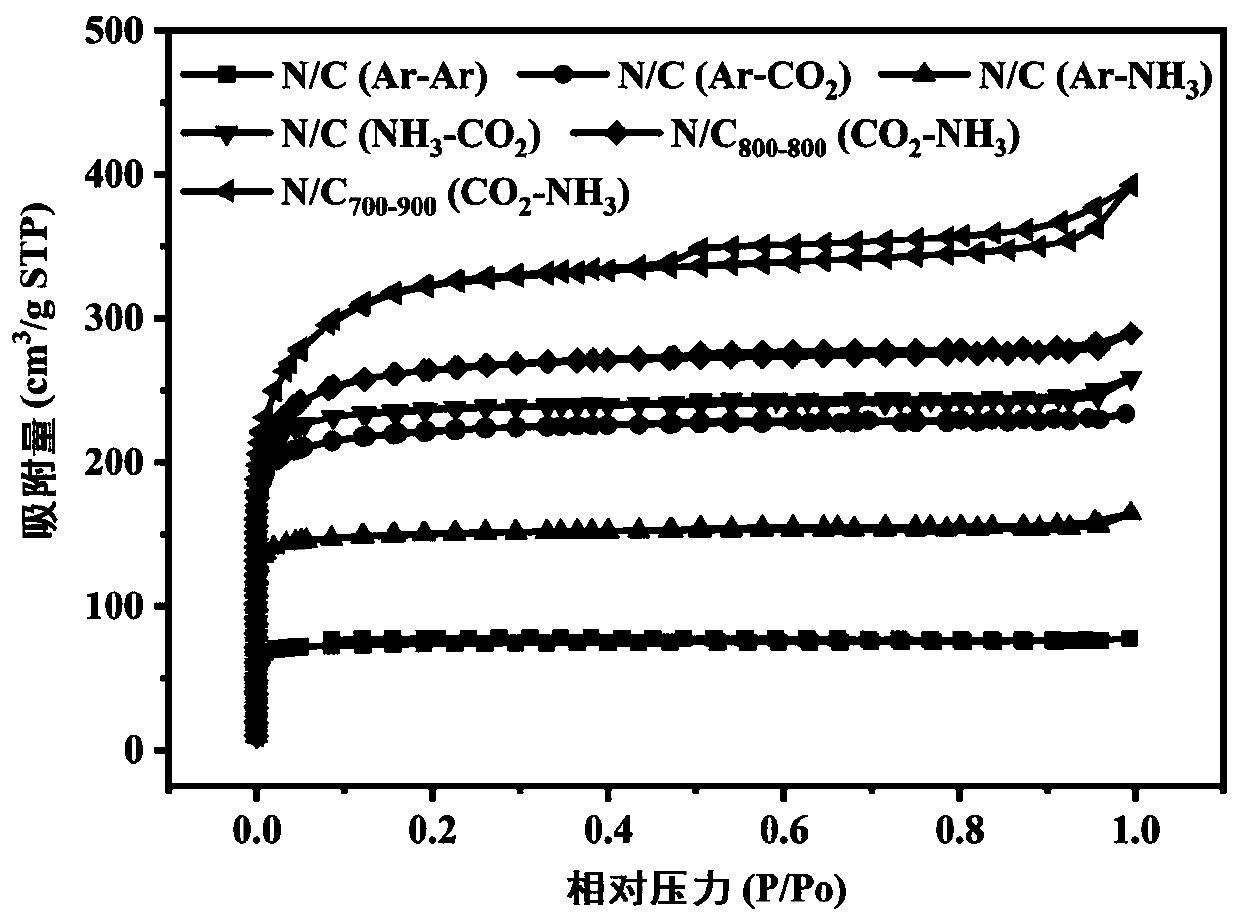

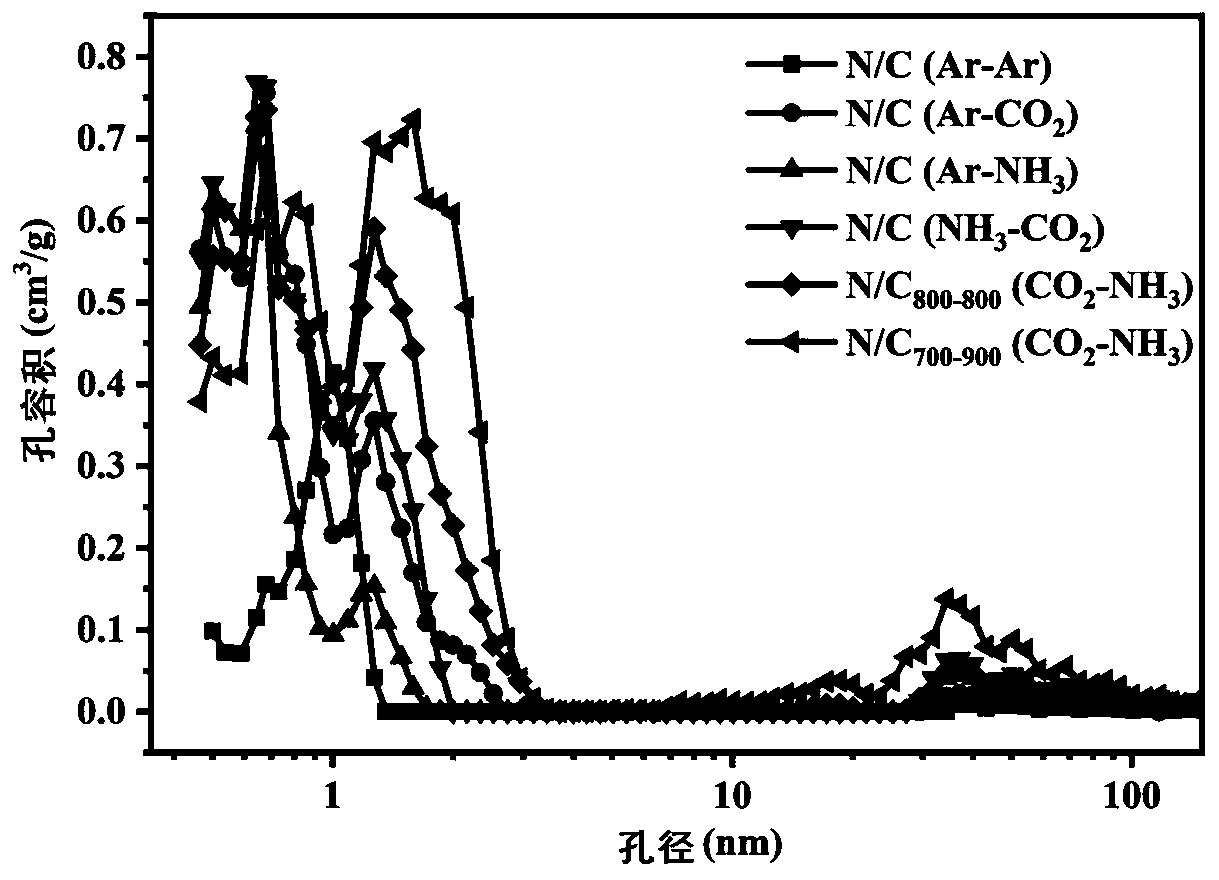

[0033] Biomass chitosan was sequentially exposed to inert gas atmosphere, CO 2 Atmosphere and NH 3 Pyrolysis is carried out in the atmosphere to obtain nitrogen-doped porous biomass carbon.

[0034]In the preparation method provided by the invention, firstly, biomass chitosan is pyrolyzed in an inert gas atmosphere. Wherein, the relative molecular mass of the biomass chitosan is preferably 300,000 to 1,000,000 Da, specifically 300,000 Da, 350,000 Da, 400,000 Da, 450,000 Da, 500,000 Da, 550,000 Da, 594,000 Da, 600,000 Da, 650,000 Da, 700,000 Da, 750,000 Da, 0,090,000 Da, 800,000 950000Da or 1000000Da; the particle size of the biomass chitosan is preferably >400 mesh; the deacetylation degree of the biomass chitosan is preferably 80-95%. In the present invention, the biomass chitosan is preferably dried and ball milled before being pyrolyzed. Wherein, ...

Embodiment 1

[0046] (1) Pretreatment: Put the biomass chitosan in an oven at 80°C for 24 hours to remove the moisture in the biomass; in order to make the distribution of biomass chitosan particles more uniform, dry it and place it in a ball mill After ball milling for 15 hours, the grinding bodies are 50 agate balls with a diameter of 3 mm, and the particle size of the biomass chitosan after ball milling is >400 mesh.

[0047] (2) Pyrolytic carbonization: Get 5g of pretreated chitosan and place it in a slow pyrolysis furnace. First, under an inert atmosphere Ar, reach 500°C with a heating rate of 5°C / min and keep for 2h; then, turn to CO 2 The atmosphere reaches 800°C at a heating rate of 10°C / min and keeps for 2 hours; finally, it is converted to NH 3 The atmosphere is kept at 800°C for 2 hours to obtain nitrogen-doped porous biomass carbon, denoted as N / C 800-800 or N / C 800-800 (CO 2 -NH 3 ).

Embodiment 2

[0049] (1) Pretreatment: Put the biomass chitosan in an oven at 80°C for 24 hours to remove the moisture in the biomass; in order to make the distribution of biomass chitosan particles more uniform, dry it and place it in a ball mill After ball milling for 15 hours, the grinding bodies are 50 agate balls with a diameter of 3 mm, and the particle size of the biomass chitosan after ball milling is >400 mesh.

[0050] (2) Pyrolytic carbonization: Get 5g of pretreated chitosan and place it in a slow pyrolysis furnace. First, under an inert atmosphere Ar, reach 500°C with a heating rate of 5°C / min and keep for 2h; then, turn to CO 2 The atmosphere reaches 700°C at a heating rate of 10°C / min and maintains for 2h; finally changes to NH 3 The atmosphere is kept at 700°C for 2 hours to obtain nitrogen-doped porous biomass carbon, denoted as N / C 700-700 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com