Automatic control method for concentration of leveling liquid

A technology of leveling liquid and concentration, applied in chemical instruments and methods, mixers, dissolving, etc., can solve the problems of clogging of leveling liquid nozzles, high cost of sewage treatment, inability to achieve unmanned operation, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

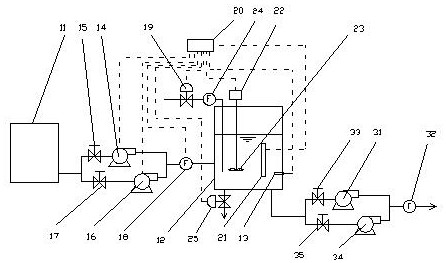

Embodiment 1

[0035] The leveling solution system of a continuous annealing unit includes a leveling solution stock solution tank 11, a leveling solution mixing tank 12, a leveling solution stock solution pump 14, a leveling solution stock solution flowmeter 18, a desalinated water replenishment solenoid valve 19, a desalinated water flow meter 24, a stirring pump 22, A leveling liquid concentration controller 20, and an agitator 23, an online leveling liquid conductivity meter 13 and a liquid level gauge 21 are set in the leveling liquid mixing tank 12, and the stirring pump 22 drives the agitator 23 to realize the uniformity of the leveling liquid in the leveling liquid mixing tank 12 Mixing, the leveling liquid is extracted from the leveling liquid mixing tank 12 by the leveling liquid supply pump 31 or the leveling liquid supply standby pump 34 to supply the leveling liquid to the leveling machine, such as figure 1 shown. During the commissioning stage, ten different types of 1%, 2%, 3%...

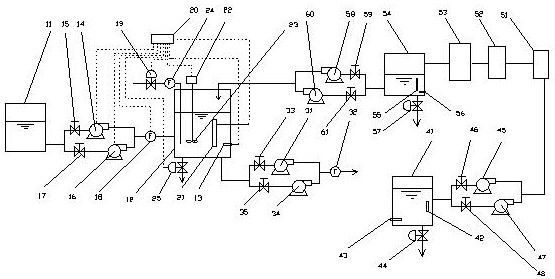

Embodiment 2

[0039] Another continuous annealing unit uses the same leveling liquid as in Example 1. In addition to the relevant devices in Example 1, the leveling liquid system is also equipped with a leveling liquid recovery tank 41, a leveling liquid purification tank 54, a leveling liquid coarse filtration device 51, and a leveling liquid. Liquid electromagnetic filter device 52 and leveling liquid fine filter device 53, the leveling liquid after leveling naturally flows into the leveling liquid recovery tank 41 by gravity, as figure 2 shown. It should be noted that, in order to make the drawing clearer, the newly added pumps, solenoid valves, liquid level gauges, conductivity meters and other equipment related to automatic control and the control connection lines between the leveling liquid concentration controller 20 are no longer drawn. It does not affect the understanding of those skilled in the art. In this embodiment, when the liquid level reaches the target liquid level (80% i...

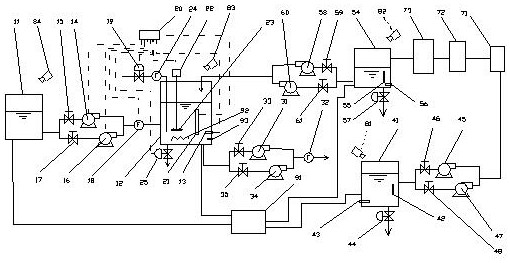

Embodiment 3

[0041] A continuous hot-dip galvanizing unit for a strip of steel, its leveling liquid system is as follows image 3 As shown, also in order to make the drawing clearer, the control connection lines between the newly added pumps, solenoid valves, liquid level gauges, conductivity meters and other equipment related to automatic control and the leveling liquid concentration controller 20 are not shown. The recovered leveling liquid is firstly filtered through the Y-type filter 71 to filter out large solid particles such as zinc skin, and then the centrifugal pump purification device 72 is used to further purify the leveling liquid, and finally the leveling liquid microfiltration device with automatic backwashing function is used 73 for final purification, and then collected into the leveling liquid purification tank 54. In this embodiment, another leveling liquid is used for leveling liquid, and the control concentration of the leveling liquid required for production is 3.5±1%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com