Humidity control method for proton exchange membrane fuel cell system

A fuel cell system and proton exchange membrane technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high requirements for external humidification equipment and high cost of use, so as to improve the use efficiency and service life, with low cost and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

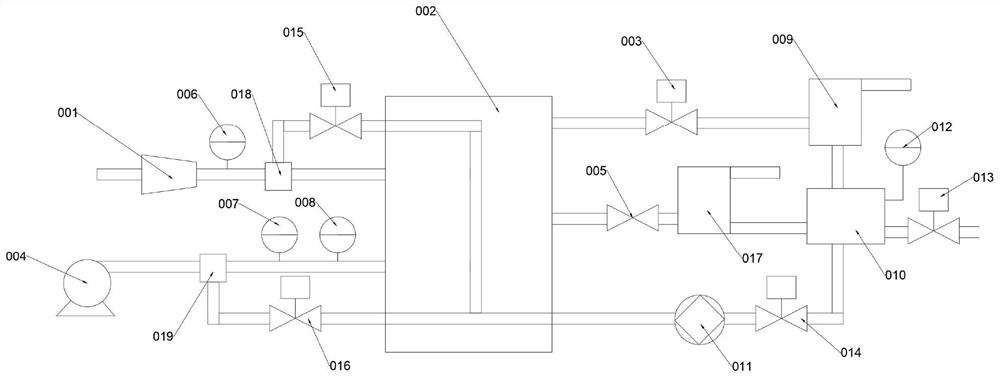

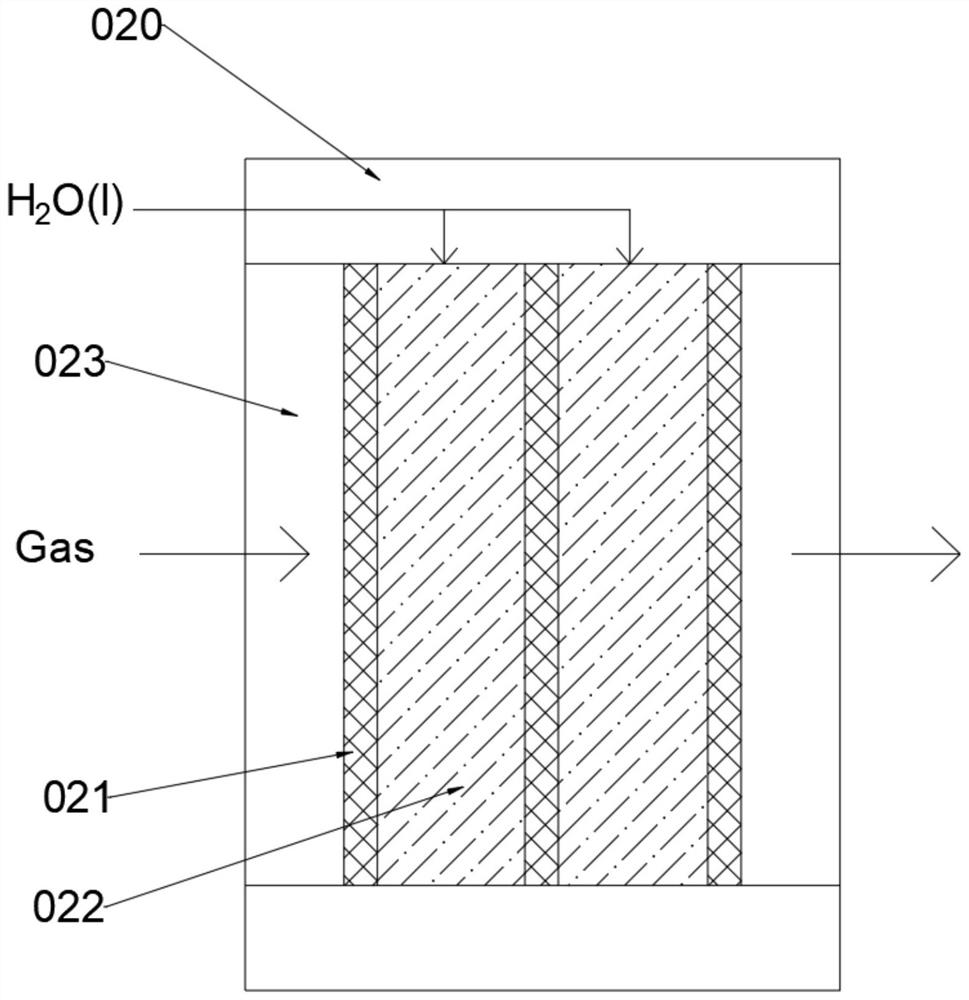

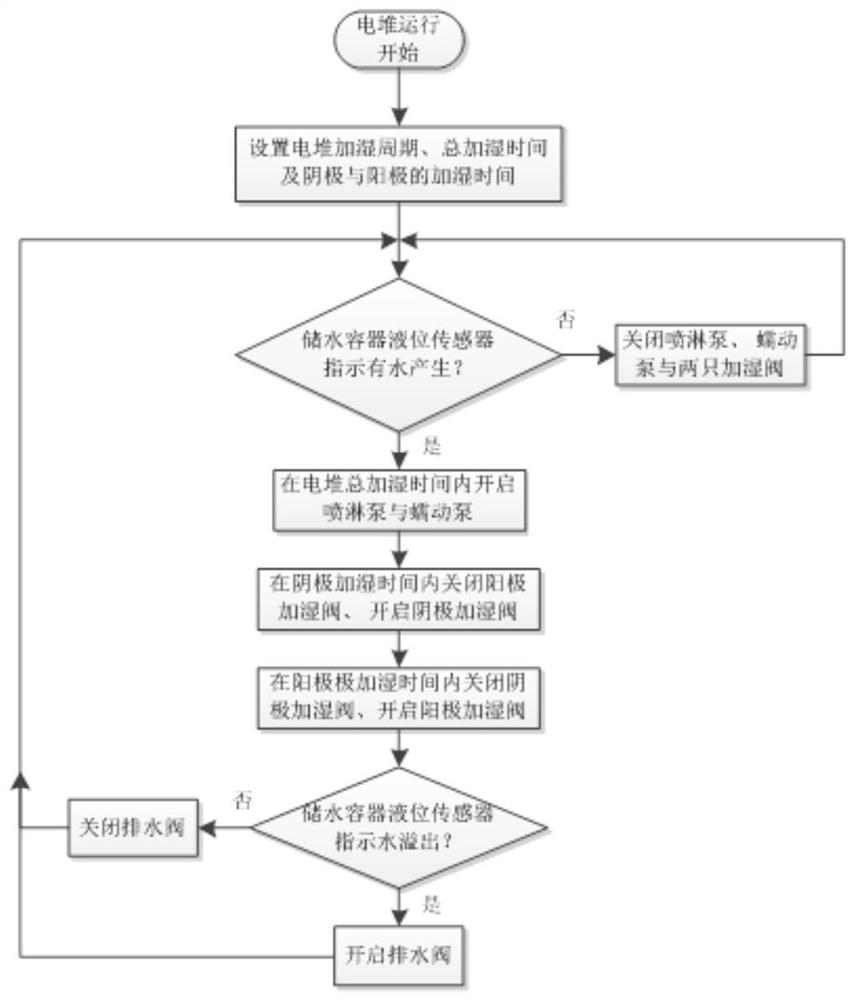

[0038] Attached below figure 1 and 2 Describe in detail.

[0039] The invention is suitable for proton exchange membrane fuel cell, that is, PEMFC, and the cell can be composed of relatively general and commonly used structures in the prior art, namely, membrane electrodes, sealing rings, and flow field plates with gas guide channels. The more important one is the membrane electrode MEA, which includes a gas diffusion layer, a catalytic layer, and a proton exchange membrane. The proton exchange membrane has the effect of not conducting electrons but being able to conduct specific ions. When hydrogen and oxygen are used as reaction raw materials, it can pass through hydrogen ions, and in other cases, it may pass through some other specific ions. However, under the consideration of preventing self-short circuit inside the battery, the proton exchange membrane is generally designed not to conduct electrons, which can prevent the positive and negative electrodes of the battery f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com