Ultralow-humidity visual detection material as well as preparation method and application thereof

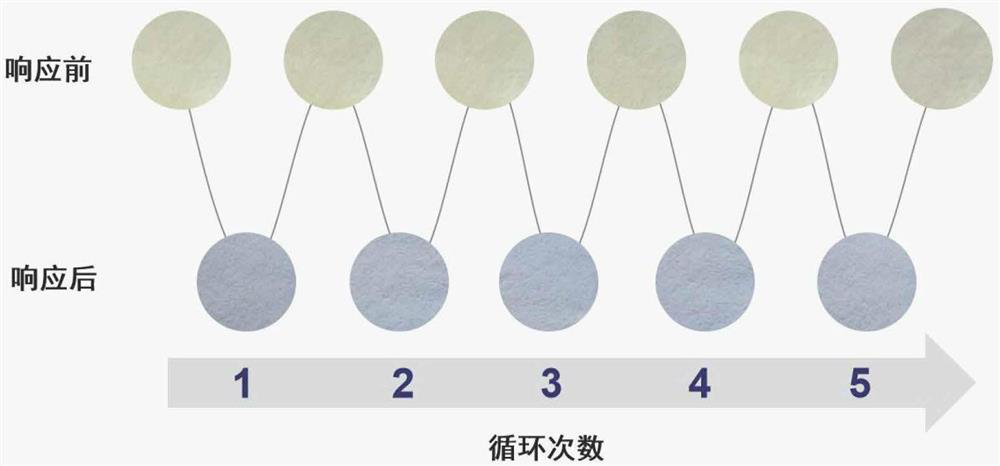

A technology for detecting materials and low humidity. It is applied in the direction of analyzing materials through chemical reactions and analyzing materials through observing the impact on chemical indicators. It can solve problems such as the inability to achieve ultra-low humidity visual detection and achieve production costs. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

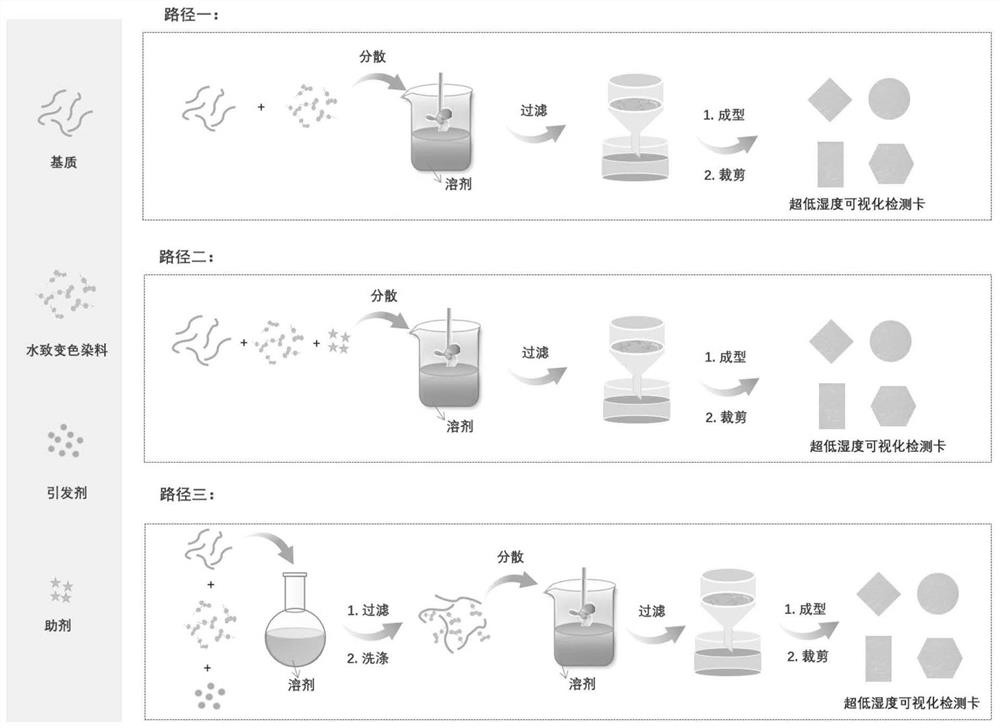

[0050] In the present invention, the preparation method of the ultra-low humidity visual detection material preferably includes the following steps: dispersing the hydrochromic molecular switch dye and the moisture-sensitive matrix in a solvent, separating the solid from the liquid, drying the obtained solid product, The ultra-low humidity visual detection material is obtained.

[0051] In the present invention, the mass ratio of the hydrochromic molecular switch dye to the solvent is preferably 0.001-1:1-200, more preferably 0.005-0.8:5-80, further preferably 0.01-0.5:10-50; The solvent preferably includes water and / or an organic solvent, more preferably an organic solvent; the organic solvent preferably includes an alcohol solvent, an ester solvent, a sulfone solvent, an amide solvent, a silane solvent, a ketone solvent, a furan solvent , one or more of halogenated alkane solvents, aromatic hydrocarbon solvents and amine solvents, more preferably methanol, ethanol, n-butanol...

Embodiment 1

[0065] according to figure 1 The flow chart shown is the preparation of the ultra-low humidity visual detection card.

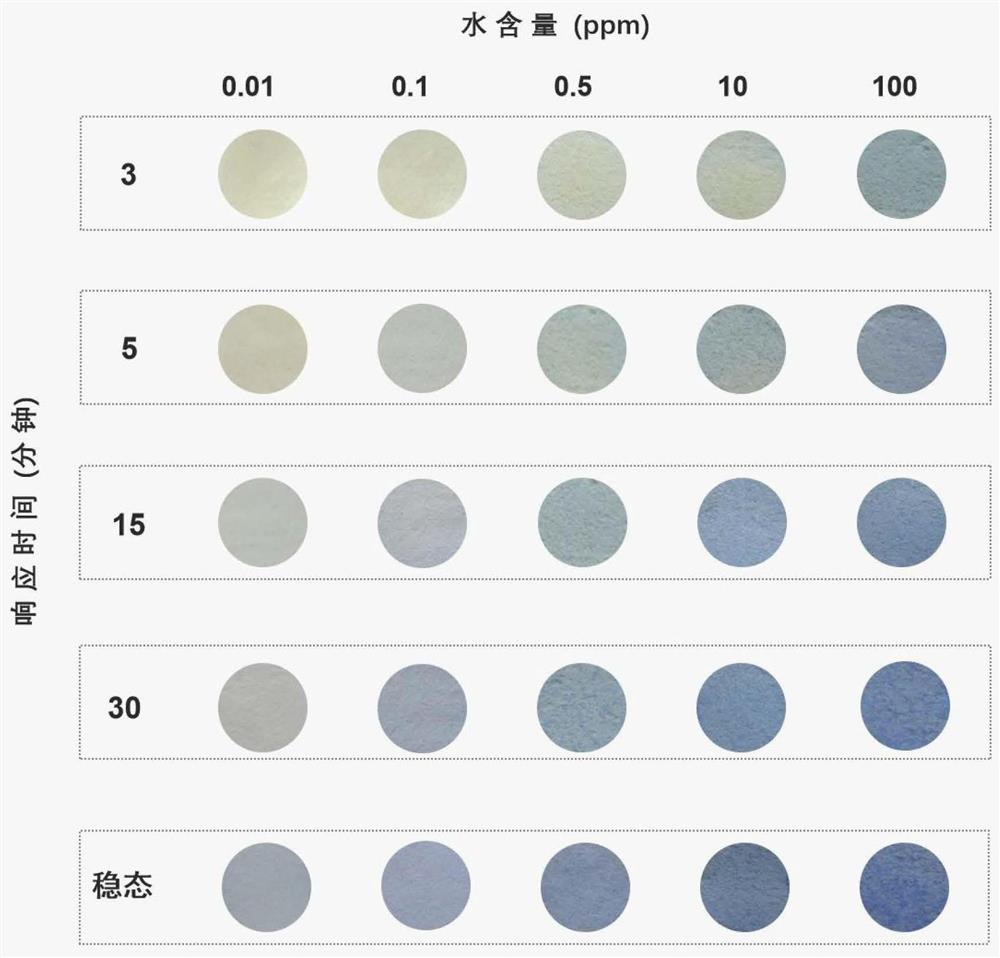

[0066] Mix 0.2 parts of 4-amino-(3',6'-bis(diethylamino)-spiro[isobenzofuran-1,9'-oxanthene]-3-one, 10 parts of filter paper microfiber and 40 parts Stir ethanol at 500rpm for 30min, suction filter and shape, dry the obtained solid product and cut it to obtain a solid product with a thickness of 0.6mm and a volume of 0.1cm 3 , Circular ultra-low humidity visual detection card (denoted as WSP).

[0067] The ultra-low humidity visual detection card prepared in this example has a detection limit of 200 ppm for humidity in the glove box. When the air humidity is ≥ 200 ppm, the ultra-low humidity visual detection card changes from light red to magenta.

Embodiment 2

[0069] according to figure 1 The flow chart shown is the preparation of the ultra-low humidity visual detection card.

[0070] 0.1 part of methyl (E)-3-((4-(2-(9,9-dimethyl-7-nitro-2,3-dihydrooxazolo[3,2-a]indole -9a (9H)-yl) vinyl) phenyl) (ethyl) amino) propionate, 10 parts of cotton microfibers and 50 parts of tetrahydrofuran alcohol were stirred at 600 rpm for 60 min, and after adding 2 parts of glycerin, they were stirred at 1000 rpm Stir for 45 minutes under the same conditions, suction filter and shape, dry the obtained solid product and cut it to obtain a 2.5cm thick product with a thickness of 0.4mm and a volume of 2.5cm 3 , Rectangular ultra-low humidity visual detection card (denoted as WSP).

[0071] The ultra-low humidity visual detection card prepared in this example has a detection limit of 250 ppm for humidity in the glove box. When the air humidity is ≥ 250 ppm, the ultra-low humidity visual detection card changes from light red to magenta.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com