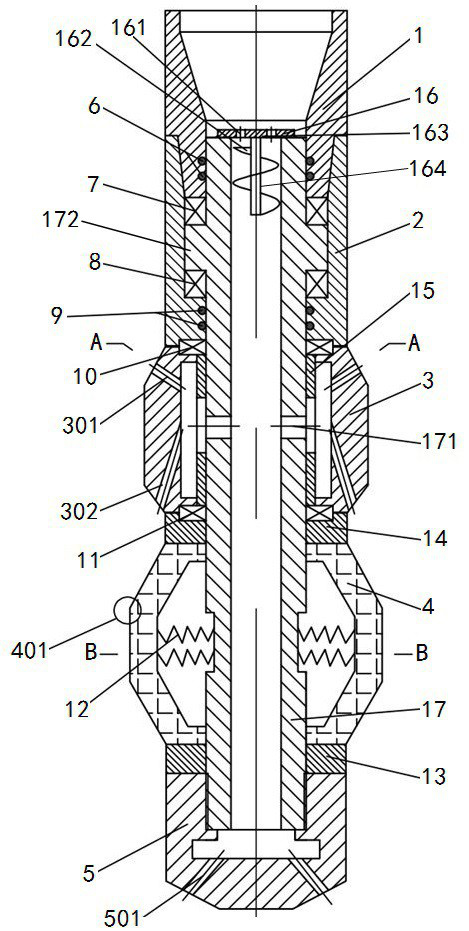

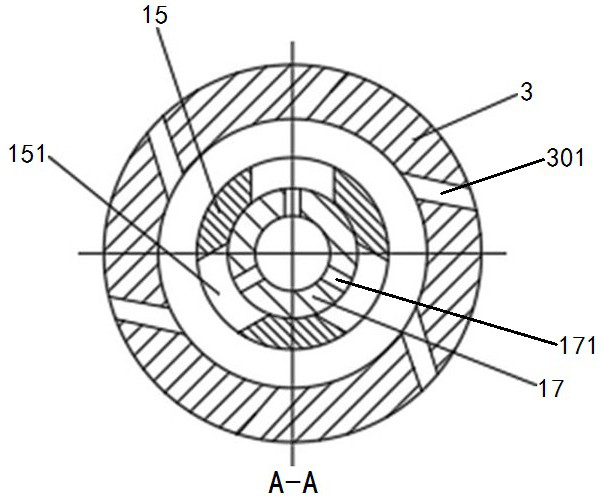

Oil pipe unblocking tool

A oil pipe and plugging removal technology, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of process pipeline blockage, small flow path, and high hardness of oil pipe wall deposits, etc., to achieve convenient formation , the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0060]Embodiment 2 of the oil pipe unblocking tool in the present invention: the difference from the above-mentioned embodiment is that an angular contact ball bearing capable of bearing a certain axial force is used between the mandrel and the bearing sleeve to realize rotational fit. There is no need to set up a ring platform.

Embodiment 3

[0061] Embodiment 3 of the oil pipe unblocking tool of the present invention: the difference from the above embodiments is that no bearing sleeve is provided, and the mandrel is directly rotatably mounted on the inner wall of the upper joint through angular contact ball bearings.

[0062] Embodiment 4 of the oil pipe unblocking tool in the present invention: the difference from the above embodiment is that the rotating lower spray head is not fixedly connected to the bottom of the mandrel, but a bit higher, and a guide head is connected to the bottom of the mandrel , the rotating lower nozzle is located above the guide head, and at this time, a communication hole is provided on the tube wall of the mandrel as a communication structure.

Embodiment 5

[0063] Embodiment 5 of the oil pipe unblocking tool of the present invention: the difference from the above embodiments is that the upper rotating nozzle is not provided with a lower flow hole, but only with an upper flow hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com