Cleaning agent for high-sulfur natural gas purification device

A technology for purifying device and natural gas, applied in the field of cleaning agents, can solve the problems of inability to remove ferrous sulfide and hydrogen sulfide at the same time, sulfur-dissolving agents are toxic to human body and the environment, and the step-by-step cleaning cycle is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

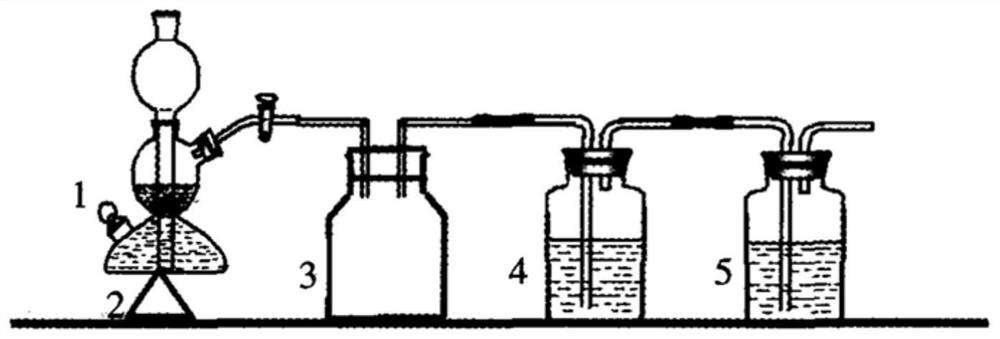

Method used

Image

Examples

Embodiment 1

[0037] The high-sulfur natural gas purification device cleaning agent of this embodiment, its constituents and its quality are respectively: 1.0 g of potassium ferrate as the main oxidation agent, 0.1 g of potassium persulfate as the oxidation auxiliary agent, and 0.1 g of potassium persulfate as the chelating auxiliary agent. Sodium 0.05g, penetration aid alkyl diglycoside 0.1g, dispersion aid sodium lauryl sulfate 0.08g, water 98.67g.

[0038] During the preparation of the high-sulfur natural gas purification device cleaning agent of this embodiment, the main oxidation agent, oxidation auxiliary agent, chelating auxiliary agent tetrasodium iminodisuccinate, penetration auxiliary agent alkyl diglycoside, and dispersion auxiliary agent twelve Sodium alcohol sulfate is dispersed in water in turn, just stir evenly.

Embodiment 2

[0040] The high-sulfur natural gas purification device cleaning agent of the present embodiment, its composition and its quality are respectively: 0.8 g of sodium ferrate as the main oxidation agent, 0.3 g of sodium persulfate as the oxidation auxiliary agent, and 0.06 g of polyaspartic acid as the chelating auxiliary agent. g, 0.2 g of penetrating aid alcohol ether triglycoside, 0.1 g of dispersing aid alcohol ether carboxylate, and 98.54 g of water.

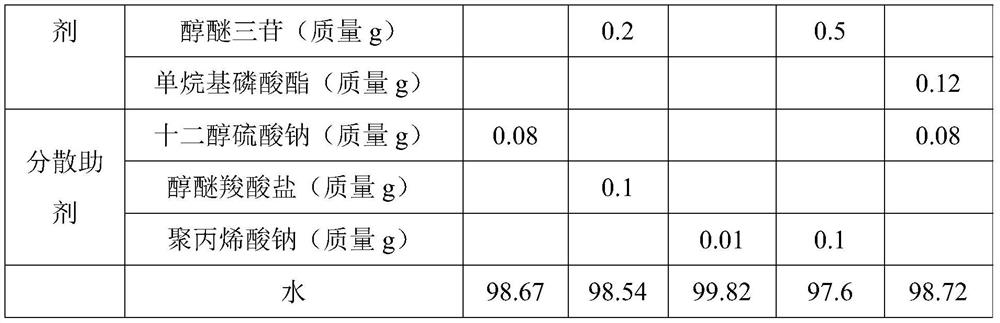

Embodiment 3-5

[0042] The formulations of cleaning agents for high-sulfur natural gas purification equipment in Examples 3-5 are listed in Table 1.

[0043] Table 1 Example 1-5 High-sulfur natural gas purification device cleaning agent formula

[0044]

[0045]

[0046] 2. Comparison ratio

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com