Formaldehyde removal product and manufacturing process thereof

A manufacturing process and technology of aldehyde products, applied in the field of aldehyde removal products and its manufacturing process, can solve the problems of limited aldehyde removal ability and limited plant respiration ability, and achieve the effect of eliminating formaldehyde pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

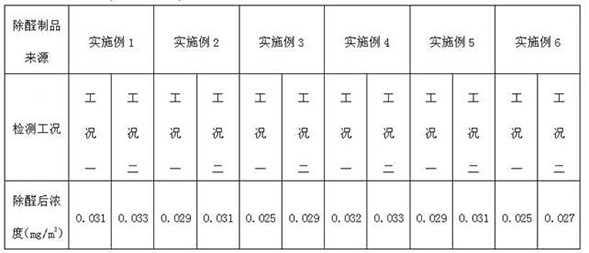

Examples

Embodiment 1

[0026] A manufacturing process for an aldehyde-removing product, comprising the steps of:

[0027] (A1) Ingredients: mixed metal cluster catalyst manganese-calcium-silicon-copper, processing aid and polymer carrier, wherein the weight ratio of metal cluster catalyst manganese-calcium-silicon-copper to polymer carrier is 1:98; The processing aid contains antioxidant, toughening agent, ultraviolet light absorber and dispersant, wherein, antioxidant accounts for 1% of polymer carrier weight, and toughening agent accounts for 5% of polymer carrier weight, and ultraviolet The light absorbing agent accounts for 1% of the weight of the polymer carrier, and the dispersant accounts for 3% of the weight of the polymer carrier; the polymer carrier is PE resin; wherein, the antioxidant includes tetrakis[β-(3,5-di-tert-butyl base-4-hydroxyphenyl)propionic acid]pentaerythritol ester, tris[2.4-di-tert-butylphenyl]phosphite, and its mass ratio is 1:2; the toughening agent is maleic anhydride ...

Embodiment 2

[0032] A manufacturing process for an aldehyde-removing product, comprising the steps of:

[0033] (A1) Ingredients: mixed metal cluster catalyst manganese-calcium-silicon-copper, processing aid and polymer carrier, wherein the weight ratio of metal cluster catalyst manganese-calcium-silicon-copper to polymer carrier is 3:44; Contain antioxidant, toughening agent, ultraviolet light absorber and dispersant in the described processing aid, wherein, antioxidant accounts for 0.6% of polymer carrier weight, and toughening agent accounts for 3% of polymer carrier weight, and ultraviolet The light absorbing agent accounts for 0.6% of the weight of the polymer carrier, and the dispersant accounts for 1.5% of the weight of the polymer carrier; the polymer carrier is PE resin; wherein, the antioxidant includes tetrakis[β-(3,5-di-tert-butyl base-4-hydroxyphenyl)propionic acid]pentaerythritol ester, tris[2.4-di-tert-butylphenyl]phosphite, and its mass ratio is 1:2; the toughening agent is...

Embodiment 3

[0038] A manufacturing process for an aldehyde-removing product, comprising the steps of:

[0039] (A1) Ingredients: mixed metal cluster catalyst manganese-calcium-silicon-copper, processing aid and polymer carrier, wherein the weight ratio of metal cluster catalyst manganese-calcium-silicon-copper to polymer carrier is 1:8; The processing aid contains antioxidant, toughening agent, ultraviolet light absorber and dispersant, wherein, antioxidant accounts for 0.3% of polymer carrier weight, toughening agent accounts for 1% of polymer carrier weight, and ultraviolet The light absorber accounts for 0.3% of the weight of the polymer carrier, and the dispersant accounts for 0.5% of the weight of the polymer carrier; the polymer carrier is PE resin; wherein, the antioxidant includes tetrakis[β-(3,5-di-tert-butyl base-4-hydroxyphenyl)propionic acid]pentaerythritol ester, tris[2.4-di-tert-butylphenyl]phosphite, and its mass ratio is 1:2; the toughening agent is maleic anhydride grafte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com