Etching method of aluminum-based copper-clad plate

An aluminum-based copper-clad laminate and etching technology, which is applied to the removal of conductive materials by chemical/electrolytic methods, secondary treatment of printed circuits, etc., can solve problems such as uneven circuit surfaces and affect the quality of aluminum substrates, and improve manufacturing yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, under the condition that there is no conflict in structure or function, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below based on examples.

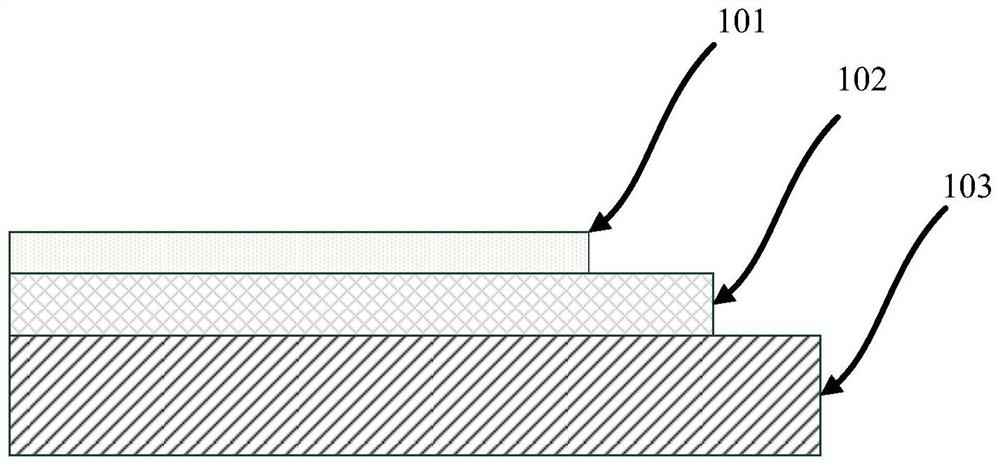

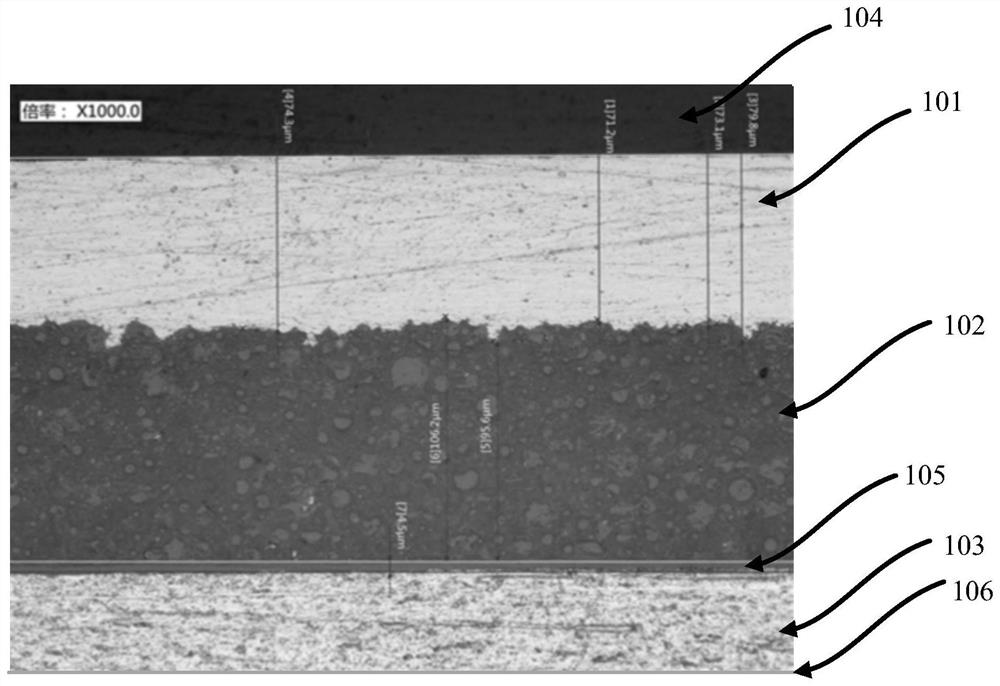

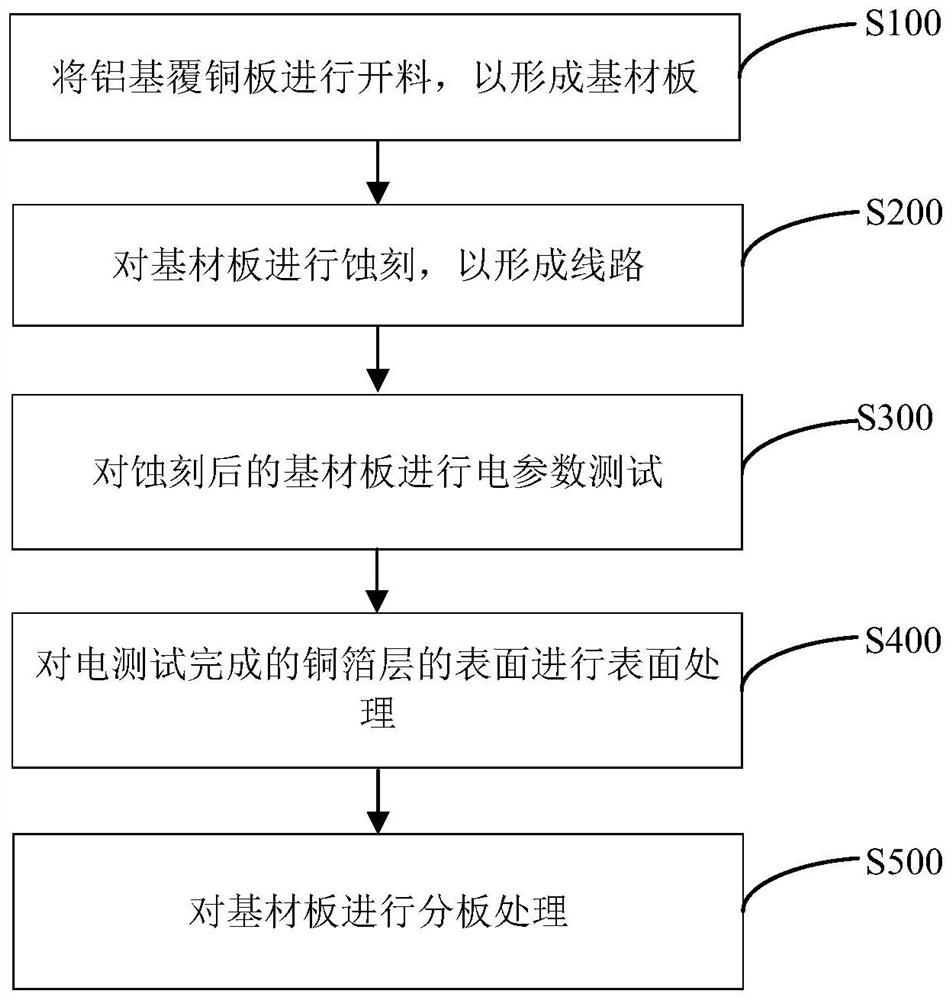

[0038] The invention provides an etching method for an aluminum-based copper-clad laminate. Aluminum-based copper-clad laminates are referred to as aluminum substrates, such as figure 1 As shown, the aluminum substrate includes three layers, the surface is a copper clad layer 101, the main component is pure copper, and its thickness is 2-15 ounces, which is mainly used to make molding circuits; the middle is an insulating layer 102, the main component is epoxy resin or Epoxy glass cloth bonding sheet, its thickness is 50-200um, its main function is insulation, so that the upper and lower metal layers are separated; the bottom surface is aluminum base layer 103, the main component is aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com