Essence component artificial sniffing device synchronized with instrument analysis and synchronization method

An instrument analysis and sniffing technology, applied in the field of analysis and detection devices, can solve the problems that mass spectrometry and artificial sniffing mouth can not fully obtain all compounds, reduce the response intensity, split flow instability, etc., and achieve low cost of instrument modification, easy verification, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

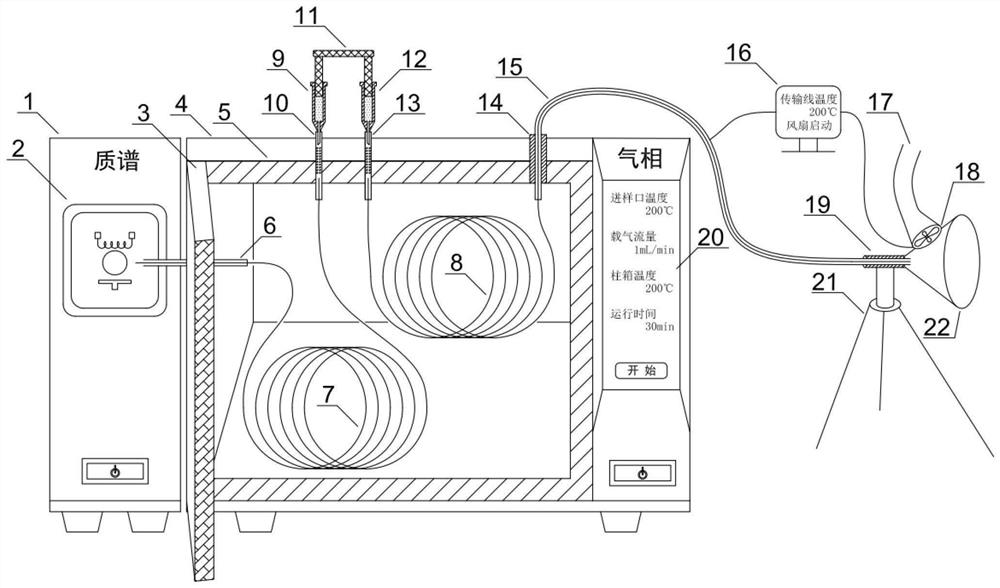

[0049] An artificial smelling device for fragrance components synchronized with instrumental analysis, comprising: a separation unit, a detection unit, and an artificial smelling unit;

[0050] Described separation unit is that gas chromatograph 4 is used for separating essence composition, is equipped with two chromatographic columns, chromatographic column A7 and chromatographic column B8, and column box 5 tops are equipped with column box outlet 14 and are connected transfer pipe 15, and described transfer pipe 15 is communicated with a sniffing hood 22 at one end outside the column box 5; the front end of the chromatographic column A7 is connected to the inlet A10, and the end is connected to the ionization chamber 2 of the mass spectrometer 1 via the mass transmission rod 6; the front end of the chromatographic column B8 is connected to Inlet B13, the end of which extends from the outlet 14 of the column box to the outside of the column box 5 and reaches the sniffing hood ...

Embodiment 2

[0057] A method for synchronizing an artificial smelling device for essence components synchronously with instrumental analysis, comprising the following steps:

[0058] Step 1. According to the characteristics of flavors and fragrances and the purpose of the research, select a suitable stationary phase and type of chromatographic column, and connect two identical chromatographic columns to a gas chromatograph and a sniffing device;

[0059] Step 2, close the column oven door 3, turn on the gas chromatograph 4 and the mass spectrometer 1, wait for the instrument to reach the detection state, set the instrument detection parameters according to the characteristics of flavors and fragrances, research purposes and chromatographic column performance;

[0060] Step 3, turn on the controller 16, set the temperature program of the transfer tube 15 to be the same as that of the column oven 5, and start the fan 18;

[0061] Step 4, select 2 to 4 representative fragrance monomer compoun...

Embodiment 3

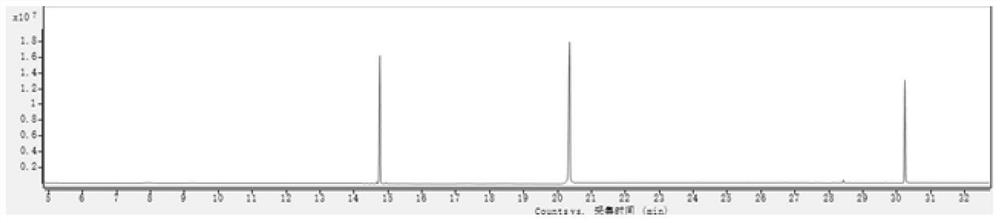

[0077] Application of an artificial sniffing device to the identification of odorant active compounds in a commercially available perfume sample

[0078] Step 1. Select 2 DB-5MS chromatographic columns (60m×0.25mm i.d.×0.25μm d.f.), and connect 2 identical chromatographic columns to the instrument and sniffing device;

[0079] Step 2, close the column oven door 3, turn on the gas chromatograph 4 and the mass spectrometer 1, and set the detection parameters: the temperature of the front and rear injection ports is 250°C, the split ratio is 10:1, and the injection volume is 1 μL; carrier gas helium, constant flow mode , 1mL / min; the oven temperature is 50°C for 2min, and the temperature is raised to 280°C at 8°C / min for 5min; the transfer line temperature is 280°C, the ion source temperature is 230°C, the ionization voltage is 70eV, the solvent delay is 4.8min, and the scanning range is 33~400amu ;

[0080] Step 3, turn on the controller 16, set the temperature program of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com