Cooling structure with slit rib laminates for turbofan engine combustion chamber and cooling method

A turbofan engine and cooling structure technology, applied in the cooling of the engine, engine components, turbine/propulsion device, etc., can solve the problems of weakening the influence of cross flow, high temperature gradient thermal failure, uneven heat flux distribution on the inner wall of the engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

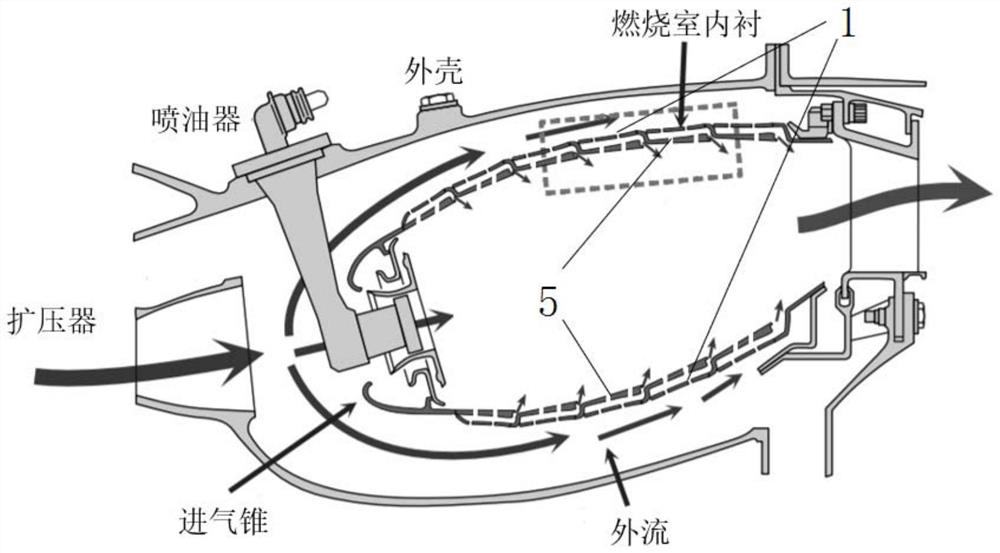

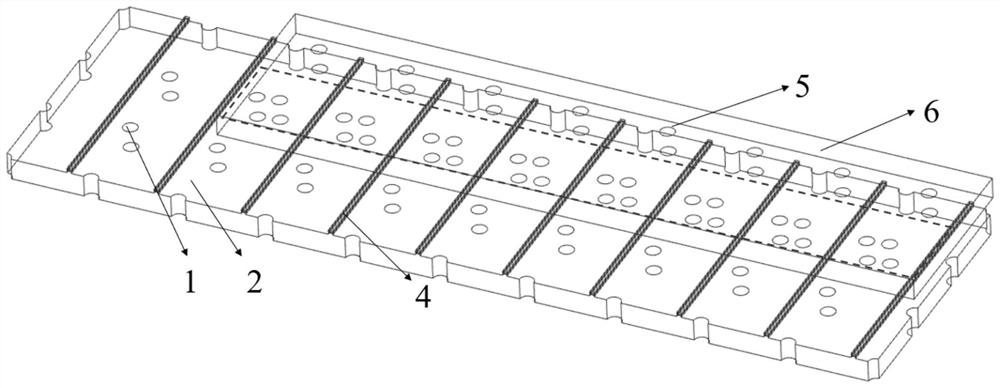

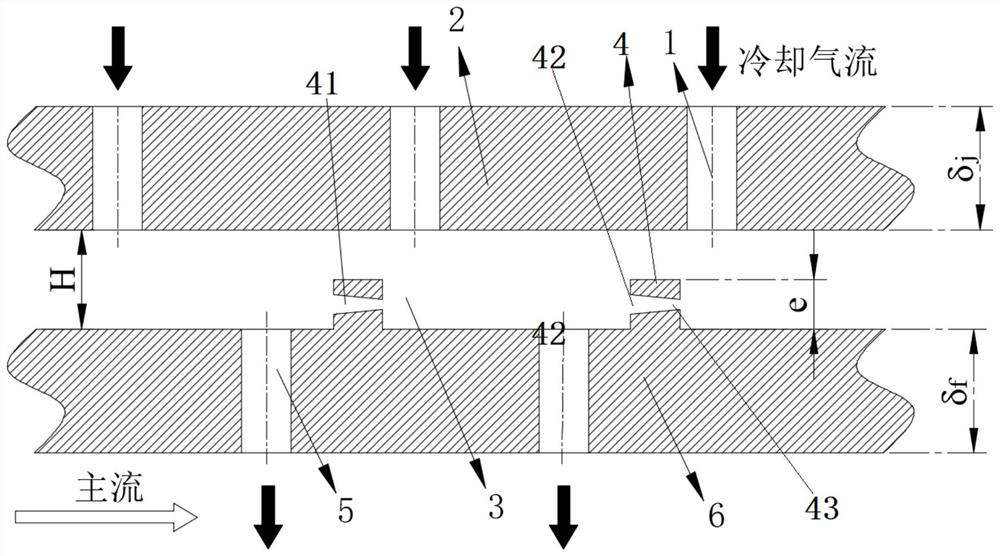

[0047] Embodiment 1: as Figure 1-4 Shown, a kind of turbofan engine combustor cooling structure with slit-ribbed laminates comprises a gas-film orifice plate 6 and an impact orifice plate 2, and the impact orifice plate 2 and the gas-film orifice plate 6 are arranged in parallel. An impingement air flow cooling passage 3 is arranged between the film orifice plate 6 and the impingement orifice plate 2, and the air film orifice plate 6, the impingement orifice plate 2 and the impingement air flow cooling passage 3 constitute the combustion chamber lining of the turbofan engine. wall structure;

[0048] On the surface of the air film orifice plate 6 located in the impingement airflow cooling channel 3, a plurality of high blockage ratio annular fins 4 are arranged along the airflow direction, and the plurality of high blockage ratio annular fins 4 are parallel to each other, and are cooled along the airflow direction. At least two contraction or expansion slits 41 for improving...

Embodiment 2

[0056] Embodiment 2: as Figure 5 As shown, a kind of cooling method that the present invention provides is as embodiment 1 turbofan engine combustor cooling structure with slit ribs, comprising the following steps:

[0057] The cooling air flow passes through the impact hole 1 to perform impact heat exchange on the inner wall surface of the air film orifice plate 6, and the cooling air flow impacting the air film orifice plate 6 diffuses to form a wall jet A, and then forms a cross flow B along the direction of the cold air flow; at this time, The high blocking ratio annular fin 4 blocks the cooling air flow, and the cross flow B interacts with the descending separated flow C formed on the upper surface of the high blocking ratio annular fin 4 to form a large recirculation zone D;

[0058] Part of the cooling airflow in the impingement airflow cooling channel 3 is ejected from the shrinking slit and interacts with the large recirculation area D, forming a first angular vortex...

Embodiment 3

[0060] Embodiment 3: as Figure 6-7 As shown, it is the same as the embodiment 1, except that the contraction or expansion slit 41 is an expansion slit, and the height of the slit entrance 42 of the expansion slit is lower than the height of the slit exit 43 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com