Adsorbing paper-free hot transferring printing and dyeing machine

A heat transfer printing and heat transfer technology, applied in rotary printing machines, printing machines, transfer printing, etc., can solve problems such as poor heat transfer performance, achieve good contact, overcome color difference or blurred patterns, and solve tensile problems and the paradoxical effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

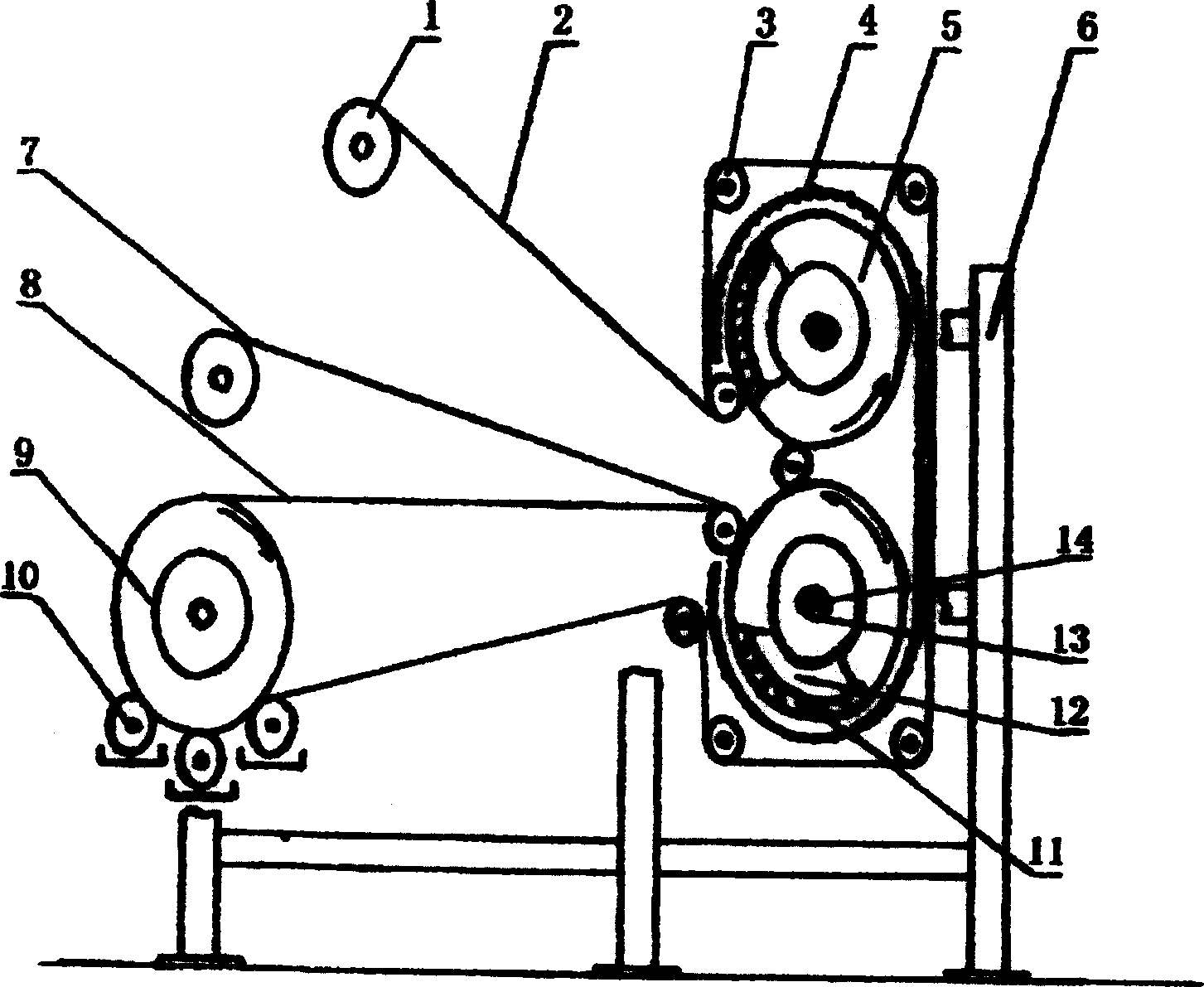

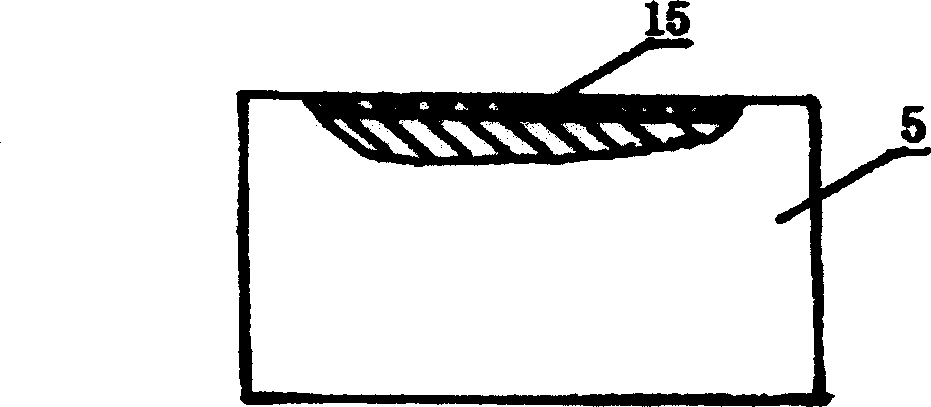

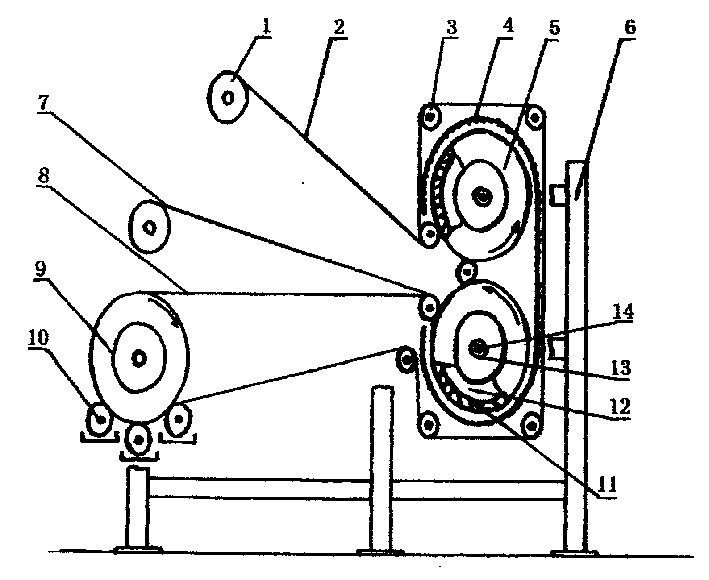

[0008] The invention relates to an adsorption type paperless thermal transfer printing and dyeing machine. The printing roller 9 and the thermal transfer roller 5 installed on the frame 6 are connected and combined by an annular metal foil 8, wherein the thermal transfer roller 5 is composed of 1-2 heating and absorbing metal foil 8 Roller 5 and surrounding radiation heating device 4 are formed. Cover or inlay a layer of magnetic material on the surface of the thermal transfer roller 5 or magnetize it as a whole, or install an electromagnetic device 15 in the roller, and select a magnetic or magnetically attracted metal foil 8 for transfer printing base material, and under the action of the metal foil pinch roller 10, it is tightly attached to the surface of the roller to increase the uniformity of heat transfer. Or the thermal transfer printing roller 5 is made into a hollow cavity 12, and the small holes 11 are evenly distributed on the annular wall, and any end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com