Nylon fiber with high color fastness to light, dyeing method of nylon fiber and preparation method of dye mother liquor

A technology of nylon fiber and dyeing method, which is applied in the direction of dyeing, textiles and papermaking, etc., can solve the problems of nylon fiber elastic damage, easy yellowing, easy fading, etc., to achieve protection strength and performance, high light fastness, color light good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

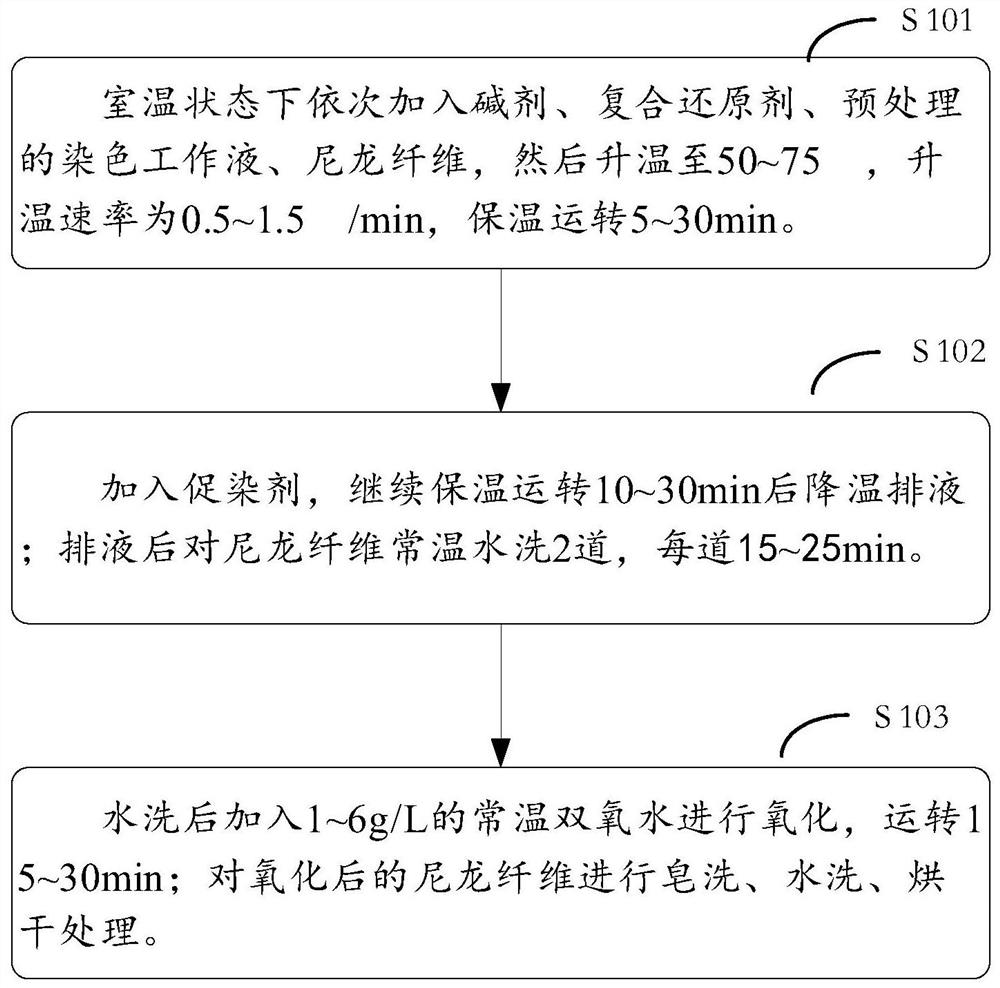

Method used

Image

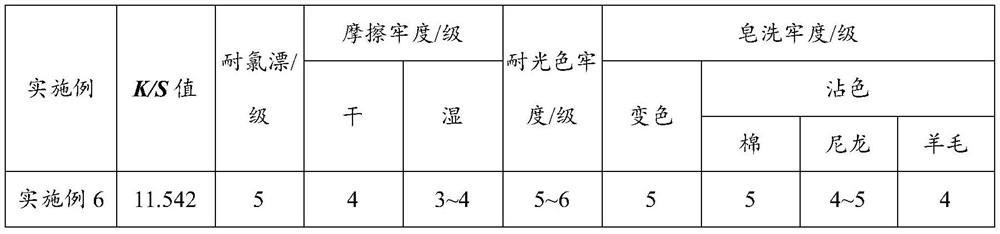

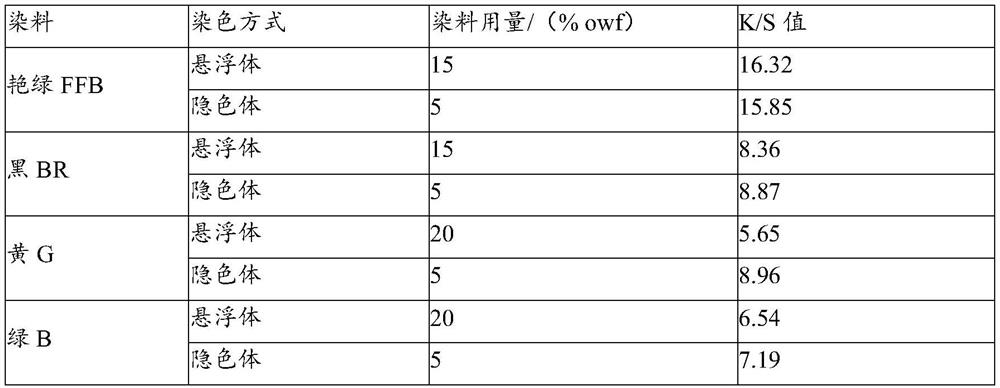

Examples

Embodiment 1

[0046] First, pretreat the dye to make a high-concentration leuco dye mother liquor, dilute the high-concentration leuco dye mother liquor by 10 to 60 times with normal temperature water, add an alkali agent and a composite reducing agent, and measure the reduction potential value and pH. Into a leuco dyeing working solution.

[0047] Prepare 100kg of nylon yarn, feed water into the dye vat, the bath ratio of nylon yarn to water is 1:20, add 2g / L sodium hydroxide and 1g / L reducing agent, dilute the dye 20 times into the dye vat in sequence Working liquid 5L, nylon yarn, control the temperature rise rate of 1°C / min to 60°C, keep warm for 25min, then add 10g / L Yuanming powder, keep warm for 10min, wash at room temperature twice, each time for 15min, add hydrogen peroxide 2g / L, run for 25min, finally add dispersant 2g / L, soaping agent 2g / L, carry out soaping, water washing, dehydration out of the vat, and drying to obtain nylon yarn with high light fastness.

Embodiment 2

[0049] First, the dye is pretreated to make a high-concentration leuco dye mother liquor.

[0050] Prepare 100kg of nylon yarn, feed water into the dye vat, the bath ratio of nylon yarn to water is 1:20, add 2g / L sodium hydroxide and 1g / L reducing agent, dilute the dye 20 times into the dye vat in sequence Working liquid 5L, nylon yarn, control the heating rate of 0.5 ℃ / min to 60 ℃, keep warm for 30 minutes, then add 10 g / L of sodium sulfate, keep warm for 10 minutes, wash twice at room temperature, 15 minutes each time, add hydrogen peroxide 2g / L, run for 25min, finally add dispersant 2g / L, soaping agent 2g / L, carry out soaping, water washing, dehydration out of the vat, and drying to obtain nylon yarn with high light fastness.

Embodiment 3

[0052] First, the dye is pretreated to make a high-concentration leuco dye mother liquor.

[0053] Prepare 100kg of nylon yarn, feed water into the dye vat, the bath ratio of nylon yarn to water is 1:20, add 2g / L sodium hydroxide and 1g / L reducing agent, dilute the dye 20 times into the dye vat in sequence Working liquid 5L, nylon yarn, control the heating rate of 1.5°C / min to 60°C, keep warm for 10min, then add 10g / L sodium sulfate, keep warm for 30min, wash twice at room temperature, 15min each time, add hydrogen peroxide 2g / L, run for 25min, finally add dispersant 2g / L, soaping agent 2g / L, carry out soaping, water washing, dehydration out of the vat, and drying to obtain nylon yarn with high light fastness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com