Cobalt-lanthanum co-doped visible light response BiVO4 photoelectrode and preparation method thereof

A visible light and photoelectrode technology, applied in electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of easy recombination of photogenerated electrons and holes, slow kinetic rate of oxygen release, poor photocatalytic water oxidation activity, etc., to achieve wide light Effects of absorption range, improvement of photoelectric catalytic performance, and enhancement of light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

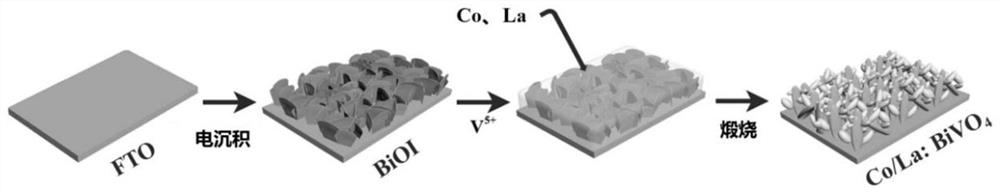

[0040] Co / La-BiVO 4 The preparation method of photoelectrode thin film, comprises the steps:

[0041] Step 1, prepare potassium iodide KI, bismuth nitrate pentahydrate Bi(NO 3 ) 3 ·5H 2 O, nitric acid HNO 3 The mixed aqueous solution of p-benzoquinone-ethanol solution is added dropwise, fully stirred, and is mixed with precursor solution 1;

[0042] Step 2. Precursor solution 1 is used as the electrolyte, and a three-electrode system is adopted, with fluorine-doped tin dioxide (FTO) transparent conductive glass as the working electrode, a platinum Pt sheet electrode as the counter electrode, and a saturated calomel electrode as the reference electrode , Electrodeposition is carried out at the relative reference electrode potential to prepare the precursor bismuth oxygen iodine BiOI thin film electrode;

[0043] Step 3, vanadyl acetylacetonate VO (acac) 2 Dissolve in DMSO as vanadium source, add cobalt source and lanthanum source to it, mix well, and prepare precursor sol...

Embodiment 1

[0053] Embodiment 1: 6.64g KI is dissolved in 100ml ultrapure water, adds concentrated nitric acid and pH is adjusted to 1.75, then adds 1.94g Bi(NO 3 ) 3 ·5H 2 O, stir for 30-60min, then add 20ml of 50mM p-benzoquinone-ethanol solution, stir for 10-20min;

[0054] A three-electrode system was used for electrodeposition, with FTO transparent conductive glass as the working electrode, a Pt sheet electrode as the counter electrode, and a saturated calomel electrode as the reference electrode. Electrodeposition was performed for 10 minutes at a potential of -0.143V relative to the saturated calomel electrode. Prepare BiOI thin film electrodes;

[0055] 0.1g VO(acac) 2 Dissolve in 2mL DMSO as the vanadium source, and add 0.7% cobalt acetylacetonate and 0.3% lanthanum acetylacetonate to it, pipette the vanadium source and coat it evenly on the BiOI thin film electrode, and dry it at 60°C;

[0056] Calcined at 450°C for 2h in a muffle furnace at a heating rate of 3°C / min;

[00...

Embodiment 2

[0065] Embodiment 2: 6.64g potassium nitrate KI is dissolved in 100mL ultrapure water, adds concentrated nitric acid and pH is adjusted to 1.75, then adds 1.94g bismuth nitrate pentahydrate Bi (NO 3 ) 3 ·5H 2 O, stir for 30-60min, then add 20mL of 50mmol / L p-benzoquinone-ethanol solution, stir for 10-20min;

[0066] A three-electrode system is used for electrodeposition, with fluorine-doped tin oxide FTO conductive glass as the working electrode, the Pt sheet electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, at a potential of -0.143V relative to the saturated calomel electrode , electrodeposited for 15min to prepare bismuth oxygen iodine BiOI thin film electrode;

[0067] 0.1g vanadyl acetylacetonate VO (acac) 2 Dissolve in 2mL dimethyl sulfoxide DMSO as the vanadium source, and add 0.5% cobalt acetylacetonate and 0.5% lanthanum acetylacetonate to it, pipette the vanadium source and evenly coat it on the BiOI thin film elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com