Trace nickel composite layered magnesium composite material as well as preparation method and application thereof

A composite material and composite layer technology, applied in the field of micro-nickel composite layered magnesium composite material and its preparation, can solve the problems of high cost, little attention to the formation of new phases and interface structure changes, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides the preparation method of the micro-nickel composite layered magnesium composite material according to the technical solution, comprising the following steps:

[0034] Magnesium powder, nickel salt and organic solvent are mixed, and the mixture is obtained after solid-liquid separation;

[0035] The mixture is calcined in a reducing atmosphere to obtain a micro-nickel composite layered magnesium composite material.

[0036] The invention adopts the conventional solid-phase method to prepare the trace nickel composite layered magnesium composite material, and the preparation method is simple and easy to operate.

[0037] In the present invention, magnesium powder, nickel salt and organic solvent are mixed, and the mixture is obtained after solid-liquid separation. In the present invention, the magnesium powder is preferably nano-magnesium, and the particle size is preferably 10-20 nm. In the present invention, the preparation method of...

Embodiment 1

[0047] Preparation of nanomagnesium: synthesis in an argon-filled glove box; first, 2 g of naphthalene, 0.1 g of Li, and 30 mL of tetrahydrofuran were added to a three-neck round-bottomed flask equipped with a mechanical stirrer and a reflux condenser, and the mixed solution was heated at 60 After refluxing at ℃ for 5 hours, lithium metal reacted with naphthalene to form lithium naphthalene, which was dark green; then, 50 mL of MeMgCl solution (concentration of 3.0 mol / L) was dropped into the above mixed solution, and stirred at 55 ℃ for 24 hours, in which Mg ions were reduced to Metal Mg core, and further aggregated into nanoparticles by Li-naphthalene in solution; after centrifugation, washing with THF, and drying under argon atmosphere to obtain magnesium powder; the oxygen and moisture content of the magnesium powder are maintained below 1ppm.

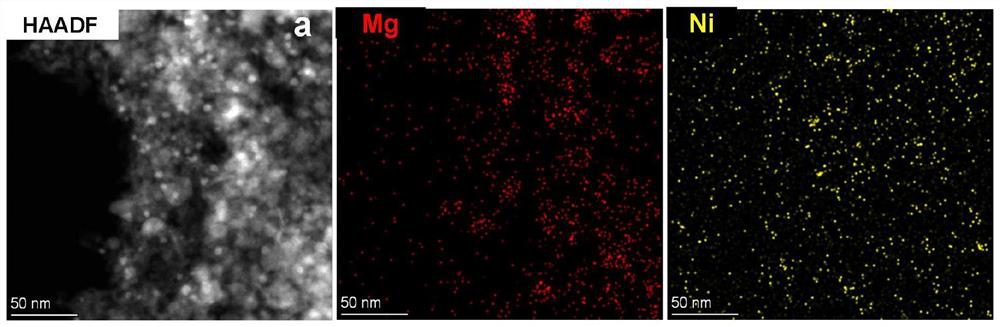

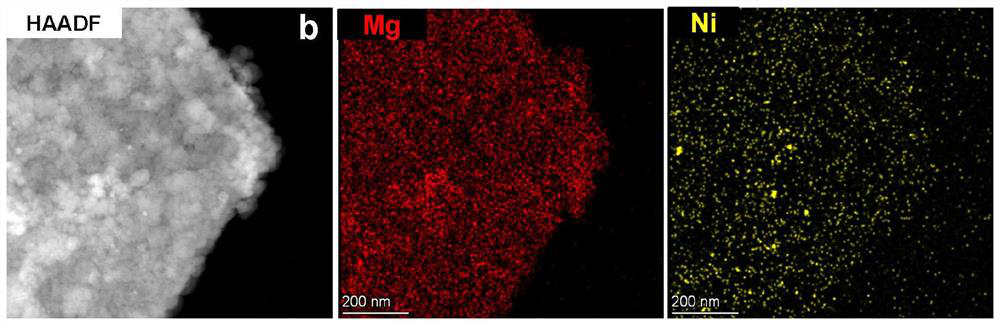

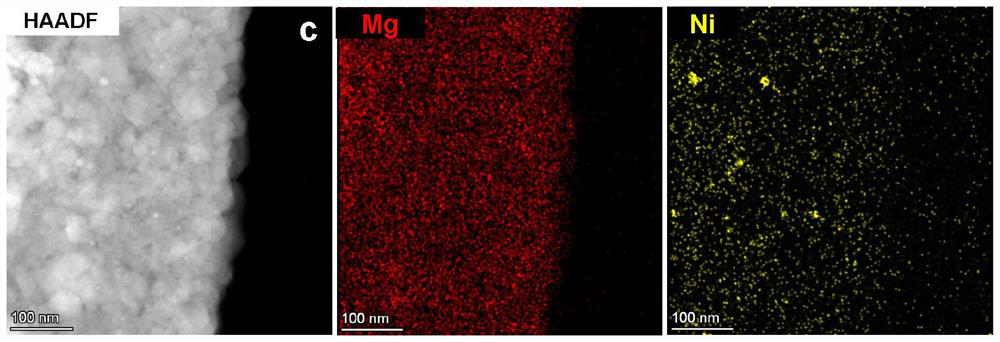

[0048] Preparation of Ni@Mg nanomaterials: Add 1 g of magnesium powder and 0.26 g of nickel acetylacetonate to the bottom of the ...

Embodiment 2

[0050] It is basically the same as Example 1, except that the mass of nickel acetylacetonate is adjusted from "0.26g" to "0.22g" during the preparation of Ni@Mg nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com