Enhanced deep nitrogen and phosphorus removal device and operation control method thereof

A technology for nitrogen and phosphorus removal and enhanced depth, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc. Nitrogen and phosphorus removal efficiency is not high, to achieve the effect of increasing denitrification and phosphorus release rate, reducing the cost of carbon source addition, and helping to maintain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

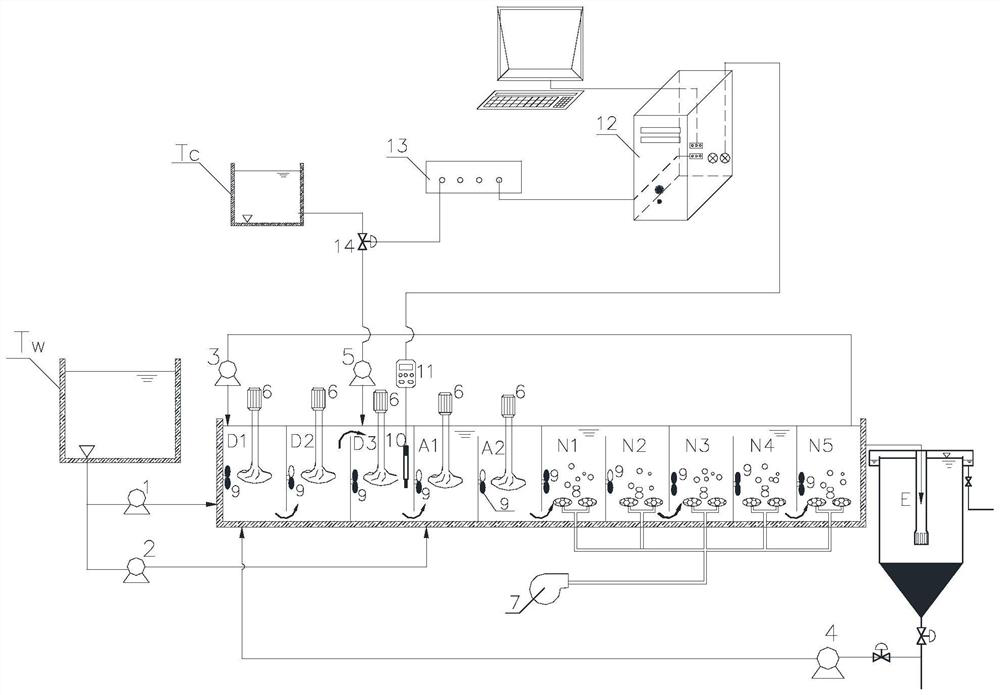

[0033] Specific implementation mode one: combine figure 1Describe this embodiment, this embodiment includes primary treatment water outlet structure Tw, main structure, first raw water pump 1, second raw water pump 2, internal circulation pump 3, sludge return pump 4, carbon source delivery pump 5, agitator 6. Blower 7, aeration device 8, water flow propeller 9, ORP online sensor 10, ORP host 11, electronic computer 12, PLC control system 13, electric valve 14, secondary sedimentation tank E and carbon source storage tank Tc; main body From left to right in the structure are anoxic first zone D1, anoxic second zone D2, anoxic transition zone D3, anaerobic first zone A1, anaerobic second zone A2, aerobic first zone N1, aerobic second zone N2, Aerobic zone 3 N3, aerobic zone 4 N4 and aerobic zone 5 N5; the first raw water pump 1 supplies the water in the primary treatment effluent structure Tw to the anoxic zone 1 D1, and the second raw water pump 2 supplies the water in the pri...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination figure 1 Describe this embodiment, the first anoxic zone D1, the second anoxic zone D2, the anoxic transition zone D3, the first anaerobic zone A1, the second anaerobic zone A2, the first aerobic zone N1, and the second aerobic zone N2 in this embodiment The volumes of the respective reaction zones of the third aerobic zone N3, the fourth aerobic zone N4 and the fifth aerobic zone N5 are equal. This setting ensures that the system can provide a total water retention time for different water qualities, which is convenient for volume design, and ensures that the discharge of ammonia nitrogen can meet the standard discharge at lower temperatures, thereby achieving the purpose of deep nitrogen and phosphorus removal. Other structures and compositions are the same as those in Embodiment 1.

specific Embodiment approach 3

[0036] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the total volume of the anoxic zone in this embodiment: the anoxic transition zone D3: the total volume of the anaerobic zone: the total volume of the aerobic zone = 2:1:2:5;

[0037] Wherein, the total volume of the anoxic zone=the volume of the first hypoxic zone D1+the volume of the second hypoxic zone D2,

[0038] The total volume of the anaerobic zone = the volume of the first anaerobic zone A1 + the volume of the second anaerobic zone A2;

[0039] The total volume of the aerobic zone = the volume of the first aerobic zone N1 + the volume of the second aerobic zone N2 + the volume of the third aerobic zone N3 + the volume of the fourth aerobic zone N4 + the volume of the fifth aerobic zone N5. Such setting ensures that the system can be designed according to the volume of different water qualities, and ensures that at lower temperatures, it is convenient to implement different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com