Modularized aluminum alloy lift car

An aluminum alloy, modular technology, used in transportation and packaging, elevators in buildings, etc., can solve the problems of inconvenient installation of handrails, difficult installation management, affecting product dimensional accuracy, etc., to reduce the difficulty of on-site installation and save installation costs. , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0025] The technical scheme of concrete implementation of the present invention is:

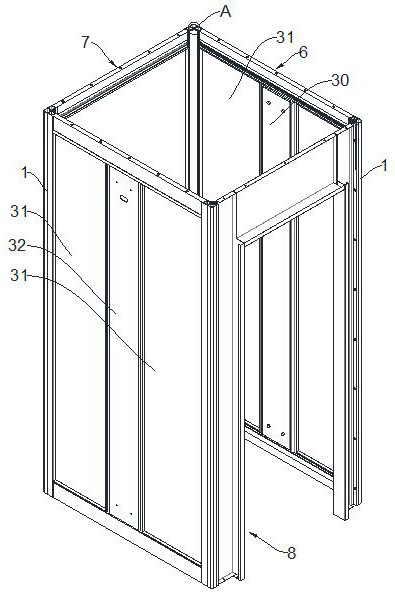

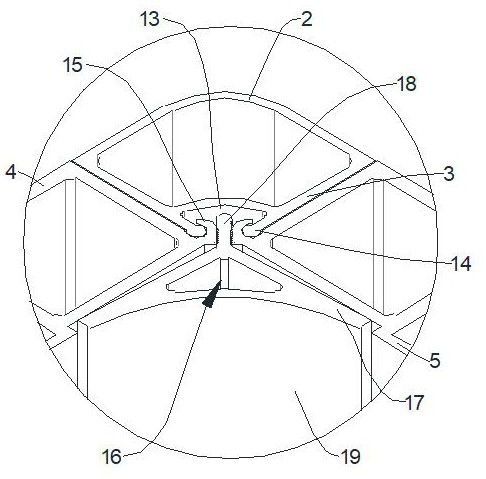

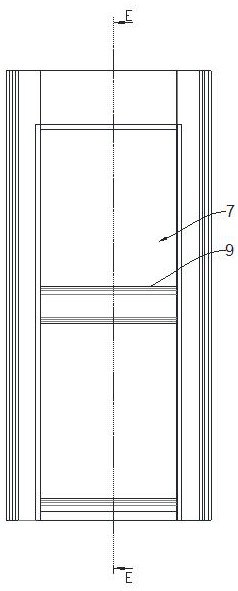

[0026] Such as Figure 1 to Figure 9 As shown, a modular aluminum alloy car includes four car walls and four columns 1, the columns 1 include a hollow main pipe 2, and the hollow main pipe 2 includes two mutually perpendicular connecting surfaces 3, each connecting surface 3 A side connector 4 is connected, and the side of the side connector 4 away from the hollow main pipe 2 is formed with a side connector slot 5, and the two sides of the car wall are respectively connected with the side connector slots of the corresponding side connector 4. 5 plug fit;

[0027] The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com