Polymer matrix composite reinforced plastic wine bottle or cosmetic bottle and preparation method thereof

A composite material and reinforced plastic technology, which is applied in the field of polymer-based composite material reinforced plastic wine bottles or cosmetic bottles, wine bottles or cosmetic bottles, and can solve the problems of being easily crushed, hidden dangers, economic losses, etc. Achieve the effect of not easily deformed and broken, improved safety, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

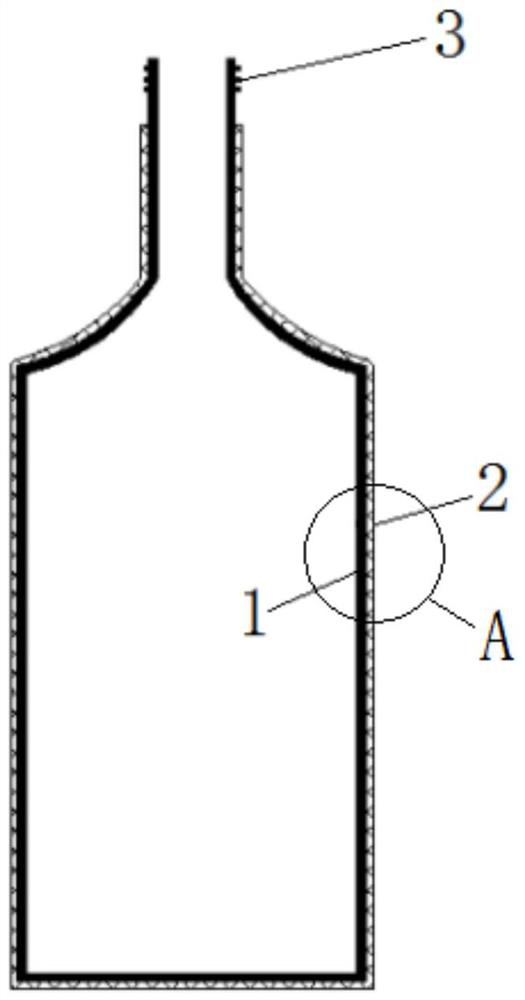

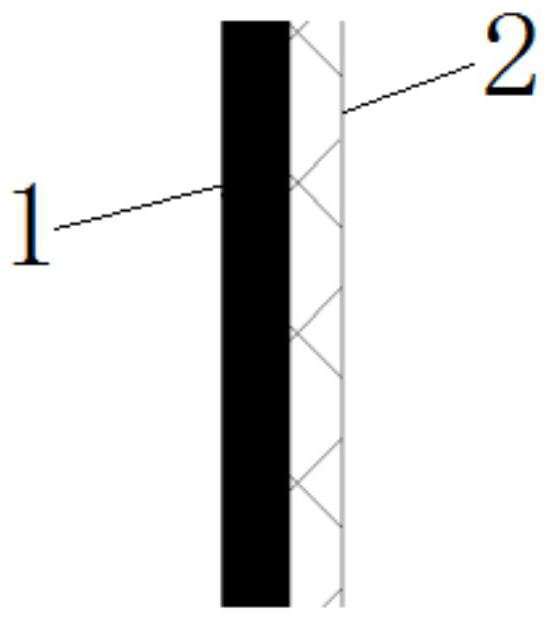

[0033] Embodiment 1: as figure 1 As shown, a wine bottle or a cosmetic bottle of a polymer-based composite material reinforced plastic includes a PET inner liner 1, and the PET inner liner 1 is made of PET (polyethylene terephthalate), Complying with food safety standards, the thickness of the entire PET lining layer 1 is between 0.2-0.5mm. A polymer-based composite material layer 2 is provided on the outer side of the PET inner liner 1. The polymer-based composite material layer 2 is formed by laying 4 layers of carbon fibers, and the thickness of the entire polymer-based composite material layer 2 is 0.2-0.5 mm. between.

[0034] Positioning chips such as GPS and Beidou can be built in the polymer-based composite material layer 2, or product labels, anti-counterfeiting marks, radio frequency chips, etc. can be set to enhance its anti-counterfeiting performance and facilitate positioning and traceability.

[0035] A bottle thread 3 is provided at the bottle mouth of the PET...

Embodiment 2

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that an outer coating is provided on the outside of the polymer-based composite material layer 2, and the outer coating plays the role of isolation and protection, which can prevent the polymer-based composite material from The resin in layer 2 is oxidized and discolored when directly exposed to the air, while improving the appearance smoothness of the entire wine bottle, improving the touch and the overall aesthetics and high-end sense of the product. The outer coating can be PU, or PA, or anti-velvet, or pearlescent, or glossy, or silicone, or film, or flame retardant, or Teflon coating. The thickness of the entire outer coating 3 is controlled between 50-200 μm. Spray patterns, product descriptions, LOGO or QR codes, etc. on the surface of the outer coating, or between the outer coating and the layer 2 of the polymer-based composite material, applicable to all colors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com