Precise spindle mounting auxiliary mechanism of multi-wire cutting equipment

An installation assistance and multi-wire cutting technology, which is applied in the field of bearing processing, can solve the problems of large shaft seat hole depth and unsuitable shaft installation conditions, etc., and achieve the effect of high-precision installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

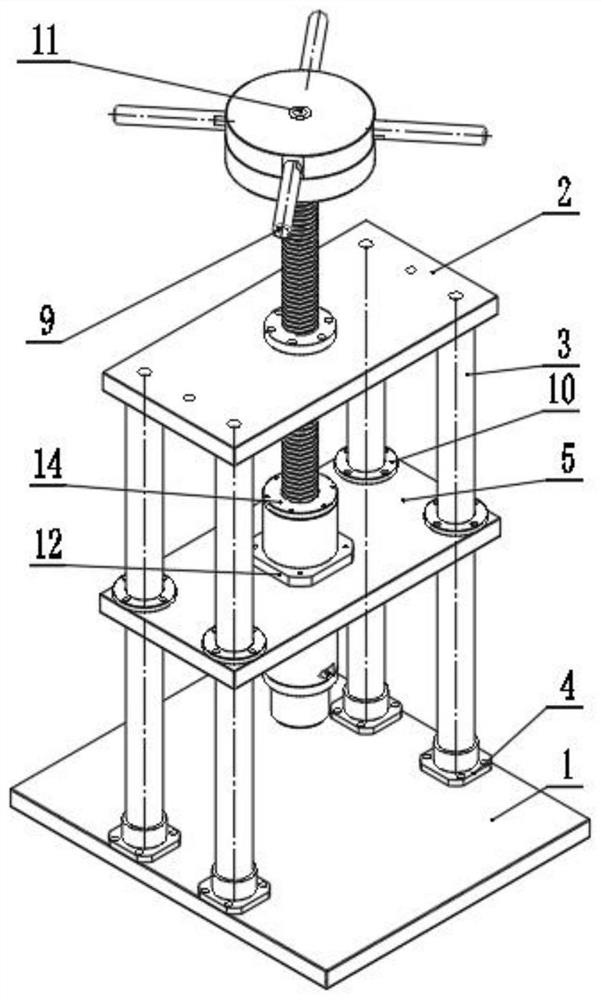

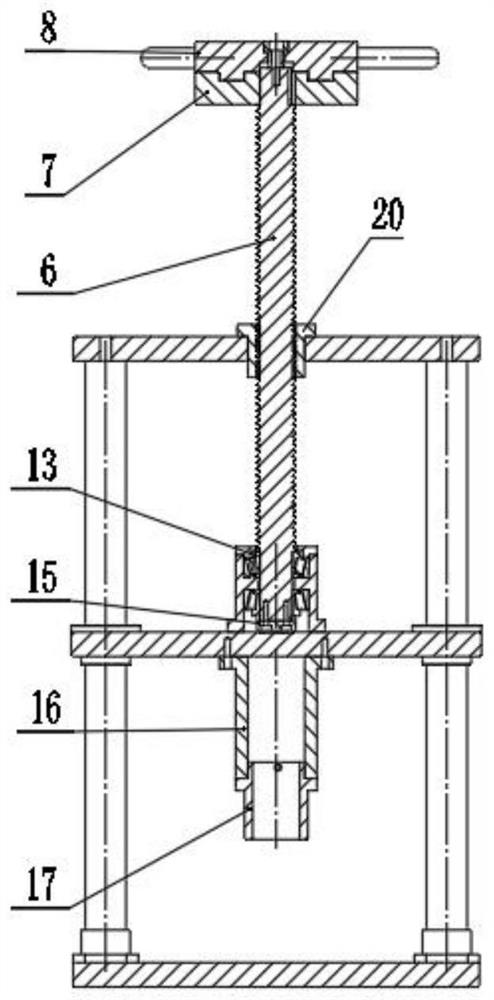

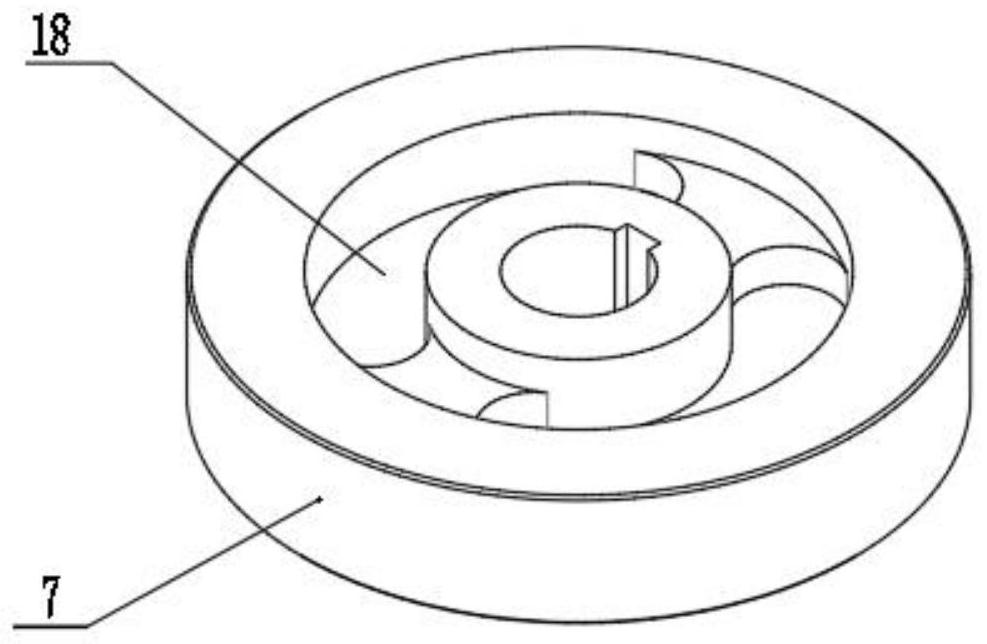

[0023] as Figure 1-4 As shown, embodiments of the present invention provides a multi-wire cutting apparatus precision spindle mounting auxiliary mechanism, comprising a substrate 1, the top of the substrate 1 is fixed connected to four guide posts 3, the top of the four guide posts 3 are connected to the lower end of the lead screw mother fixing plate 2, the screw mother fixing plate 2 is fixed within the pivot through hole is fixed with a lead screw pair 20, the lead screw mother fixing plate 2 and the substrate 1 is provided with a pressure seat 5, the lead screw pair 20 internal thread is connected to the lead screw 6, the top of the lead screw 6 is connected to the fixing disc 7 through the key, The top of the fixing plate 7 is provided with two ring grooves 18, the top rotation of the fixing disc 7 is connected to the rotating disc 8, the lower end of the rotating disc 8 is fixed to have two impact blocks 19, the pressure seat 5 is fixed to the top of the central shaft of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com