Arginine/lysine polypeptide microcapsule inclusion as well as preparation method and application thereof

A technology of arginine and lysine, which is applied in the field of arginine/lysine polypeptide microcapsule inclusions and its preparation, can solve the problems of organic solvent residues, structural changes, expensive equipment, etc. release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

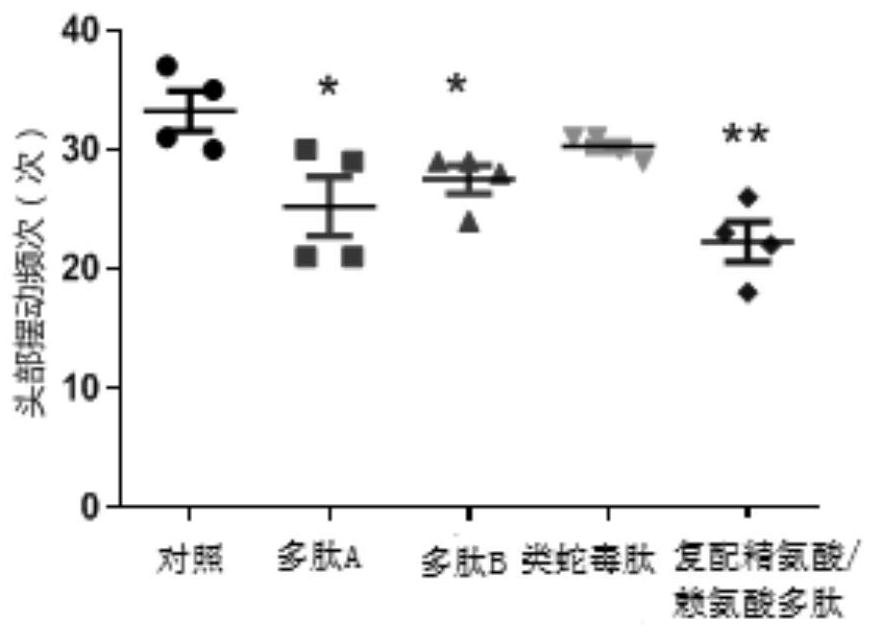

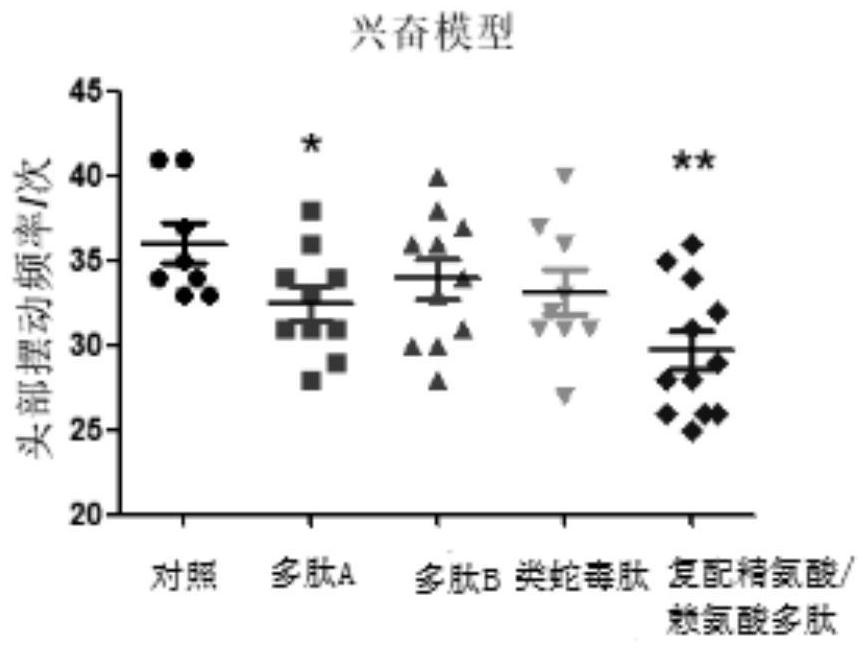

Examples

Embodiment 1

[0033] An arginine / lysine polypeptide microcapsule inclusion, comprising the following raw materials in parts by weight:

[0034] 0.002% compounded arginine / lysine polypeptide, 10% glycerin, 0.1% polyglyceryl-10 diisostearate, 0.1% polyglyceryl-10 laurate and 0.0001% dextran, remaining The amount is water; wherein, the compound arginine / lysine polypeptide is polypeptide A and polypeptide B with a mass ratio of 3:1, and the polypeptide A is red scorpion toxin, purchased from Zhejiang Paitide Biological Co., Ltd., model ZPC -019S; the polypeptide B is a conotoxin peptide, purchased from Zhejiang Paidetide Biological Co., Ltd., model ZPC-018S.

[0035] The preparation method of the above-mentioned arginine / lysine polypeptide microcapsule inclusions comprises the following steps:

[0036] 1) Fully stir and dissolve the compounded arginine / lysine polypeptide, polyglyceryl-10 diisostearate, polyglyceryl-10 laurate, glycerin, and dextran to obtain a uniform mixed solution.

[0037]...

Embodiment 2

[0039] An arginine / lysine polypeptide microcapsule inclusion, comprising the following raw materials in parts by weight:

[0040]0.005% compounded arginine / lysine polypeptide, 30% glycerin, 1% polyglyceryl-10 diisostearate, 0.5% polyglyceryl-10 laurate and 0.1% dextran, the remainder The amount is water; wherein, the compound arginine / lysine polypeptide is polypeptide A and polypeptide B with a mass ratio of 9:1, and the polypeptide A is red scorpion toxin, which is purchased from Zhejiang Paitide Biological Co., Ltd., and the model is ZPC -019S; the polypeptide B is a conotoxin peptide, purchased from Zhejiang Paidetide Biological Co., Ltd., model ZPC-018S.

[0041] The preparation method of the above-mentioned arginine / lysine polypeptide microcapsule inclusions comprises the following steps:

[0042] 1) Fully stir and dissolve the compounded arginine / lysine polypeptide, polyglyceryl-10 diisostearate, polyglyceryl-10 laurate, glycerin, and dextran to obtain a uniform mixed s...

Embodiment 3

[0045] An arginine / lysine polypeptide microcapsule inclusion, comprising the following raw materials in parts by weight:

[0046] 0.01% compounded arginine / lysine polypeptide, 20% glycerin, 0.5% polyglyceryl-10 diisostearate, 0.2% polyglyceryl-10 laurate and 0.005% dextran, the remainder The amount is water; wherein, the compound arginine / lysine polypeptide is polypeptide A and polypeptide B with a mass ratio of 5:1, and the polypeptide A is red scorpion toxin, purchased from Zhejiang Paitide Biological Co., Ltd., the model is ZPC -019S; the polypeptide B is a conotoxin peptide, purchased from Zhejiang Paidetide Biological Co., Ltd., model ZPC-018S.

[0047] The preparation method of the above-mentioned arginine / lysine polypeptide microcapsule inclusions comprises the following steps:

[0048] 1) Fully stir and dissolve the compounded arginine / lysine polypeptide, polyglyceryl-10 diisostearate, polyglyceryl-10 laurate, glycerin, and dextran to obtain a uniform mixed solution. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com