Thermochromic anti-pollution flashover silicone rubber composition

A silicone rubber composition, temperature-sensitive color change technology, applied in coatings, heat-sensitive coatings, etc., can solve the problems of insufficiency to ultraviolet radiation, failure, etc., achieve excellent weather resistance, and facilitate manual or equipment identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

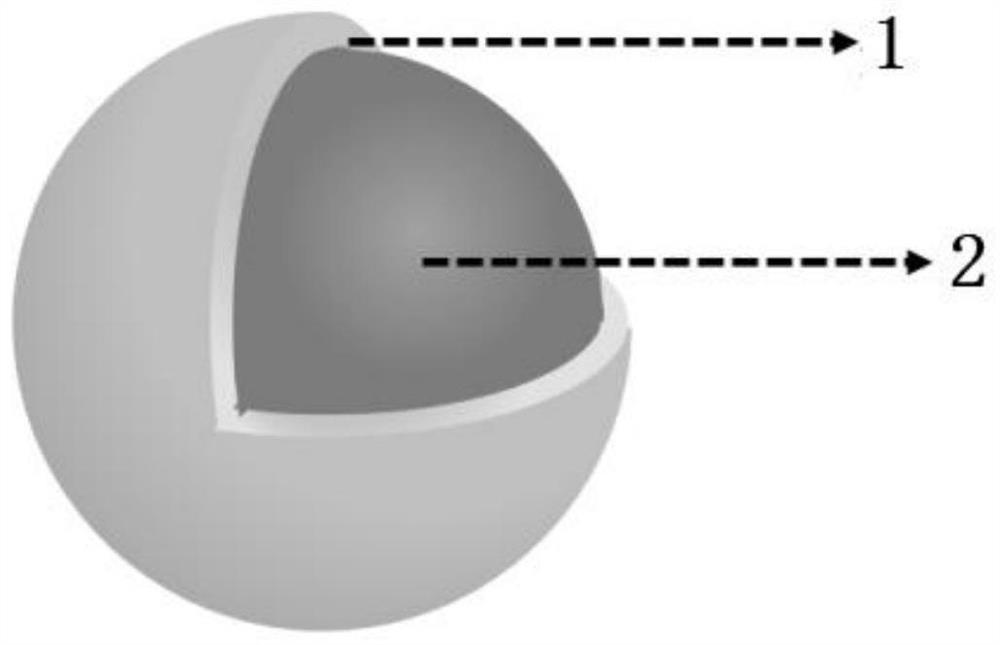

[0040] Main color-changing particles: nickel-containing compound Ni(NH 4 )PO 4 ·6H 2 O is the outer layer 1, with spherical alumina as the inner core 2, the main color-changing particles have an average particle size of 50nm; the synergistic particles are phthalocyanine green, and the average particle size is 2μm.

[0041] (1) In the kneader, add 100kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000mPa.s, add 0.5kg of hydroxyl silicone oil, add 10kg of hydrophobically modified nano-silica, stir and knead evenly, and then add 2kg The above-mentioned main color-changing particles and 0.1 kg of phthalocyanine green, wherein, the mass of the outer layer 1: the mass of the inner core 2 is 15:100; add 90 kg of aluminum hydroxide, add 20 kg of silicon micropowder, and fully knead evenly.

[0042] (2) Process the uniformly kneaded rubber material for 3 times with a three-roll mill to further disperse evenly.

[0043] (3) The above-mentioned uniformly kneaded ru...

Embodiment 2

[0046] Main color-changing particles: Cobalt-containing compound Co 3 (PO 4 ) 2 ·8H 2 O is the outer layer 1, with spherical alumina as the inner core 2, the average particle size of the main color-changing particles is 100nm; the synergistic particle is iron yellow, and the average particle size is 2μm.

[0047] (1) In the kneader, add 100kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000mPa.s, add 0.5kg of hydroxyl silicone oil, add 10kg of hydrophobically modified nano-silica, stir and knead evenly, and then add 2kg The above-mentioned main color-changing particles and 0.5kg iron yellow, wherein the mass of the outer layer 1: the mass of the inner core 2 is 22:100; add 90kg of aluminum hydroxide, add 20kg of silicon micropowder, fully knead evenly.

[0048] (2) Process the uniformly kneaded rubber material for 3 times with a three-roll mill to further disperse evenly.

[0049] (3) The above-mentioned uniformly kneaded rubber is added to a planetary ...

Embodiment 3

[0052] Main color-changing particles: with vanadium-containing compound NH 4 ·VO 3 It is the outer layer 1, and the spherical alumina is the inner core 2. The average particle size of the main color-changing particles is 200nm; the synergistic particle is titanium dioxide, and its average particle size is 5μm.

[0053] (1) In the kneader, add 50kg of viscosity of 1000mPa.s and 50kg of vinyl-terminated polydimethylsiloxane with viscosity of 5000mPa.s, add 2kg of hexamethyldisilazane, add 0.6kg of γ-glycidol Etheroxypropyltrimethoxysilane, add 100kg of aluminum hydroxide, add 10kg of hydrophobically modified nano-silica, heat up to 160°C, stir and knead for 1h, then stir and knead under reduced pressure for 1h, after kneading evenly, drop to Room temperature; add 5kg of the above-mentioned main color-changing particles and 1kg of titanium dioxide, wherein the quality of the outer layer 1: the quality of the inner core 2 is 10:100; add 20kg of silicon micropowder and continue mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com