Resin composition as well as preparation method and application thereof

A technology of resin composition and compound, applied in the field of resin composition and its preparation, can solve the problems of weakened effect and short service life, and achieve the effect of small decline and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

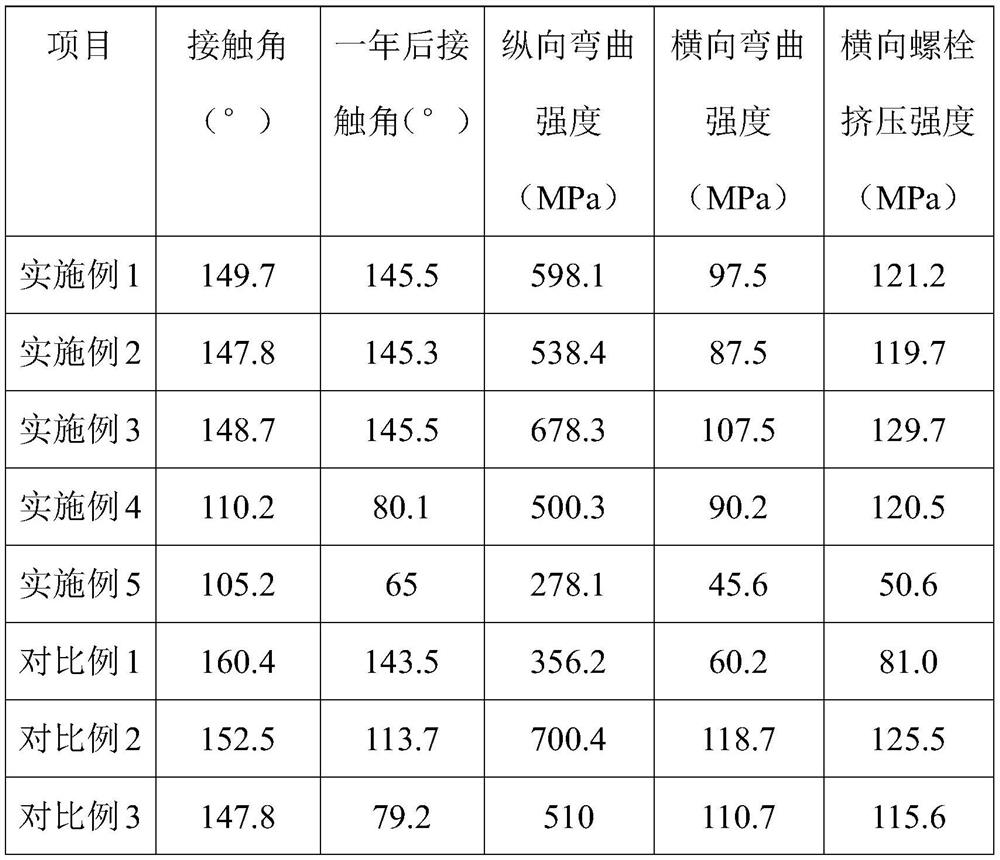

Examples

Embodiment 1

[0067] The present embodiment provides a resin composition, the resin composition comprises 55 parts vinyl ester resin, 10 parts hydrophobic group compound, 5 parts nano titanium dioxide, 2 parts curing agent, 2 parts internal release agent, 4.5 parts low shrinkage agent, 18 parts filler and 3.5 parts color paste.

[0068] The present embodiment provides a method for preparing the resin composition, the specific steps comprising:

[0069] According to the amount of formulation, the vinyl ester resin, hydrophobic group compounds, nano titanium dioxide, curing agent, internal release agent, low shrinkage agent, filler and color paste mixed to obtain the resin composition.

[0070] The present embodiment provides a composite material, the composite material comprises a glass fiber and the resin composition, the mass percentage content of the glass fiber in the composite material is 55%; the specific preparation method is as follows:

[0071] After impregnating the glass fiber with re...

Embodiment 2

[0073] The present embodiment provides a resin composition, by weight the resin composition comprises 60 parts vinyl ester resin, 15 parts hydrophobic group compound, 3 parts nano titanium dioxide, 2.5 parts curing agent, 0.5 parts inner release agent, 6 parts low shrinkage agent, 18 parts filler and 3.5 parts color paste.

[0074] The present embodiment provides a method for preparing the resin composition, the specific steps comprising:

[0075] According to the amount of formulation, the vinyl ester resin, hydrophobic group compounds, nano titanium dioxide, curing agent, internal release agent, low shrinkage agent, filler and color paste mixed to obtain the resin composition.

[0076] The present embodiment provides a composite material, the composite material comprises a glass fiber and the resin composition, the mass percentage content of the glass fiber in the composite material is 65%; the specific preparation method is the same as Example 1.

Embodiment 3

[0078] The present embodiment provides a resin composition, by weight the resin composition comprises 70 parts of vinyl ester resin, 8 parts of hydrophobic group compound, 7 parts of nano titanium dioxide, 3 parts of curing agent, 4 parts of internal release agent, 2 parts of low shrinkage agent, 4 parts of filler and 2.5 parts of color paste.

[0079] The present embodiment provides a method for preparing the resin composition, the specific steps comprising:

[0080] According to the amount of formula, the vinyl ester resin, hydrophobic compounds, titanium dioxide, curing agents, internal release agents, low shrinkage agents, fillers and color pastes are mixed to give the resin composition.

[0081] The present embodiment provides a composite material, the composite material comprises a glass fiber and the resin composition, the mass percentage content of the glass fiber in the composite material is 70%; the specific preparation method is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Longitudinal bending strength | aaaaa | aaaaa |

| Transverse bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com