Antibacterial agent for producing modified plastic and preparation method thereof

A technology of antibacterial agents and plastics, which is applied in the field of antibacterial agents for the production of modified plastics and its preparation, can solve the problems of short antibacterial timeliness, poor antibacterial effect of antibacterial agents, and single function, so as to improve service life, antibacterial effect, and antibacterial long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

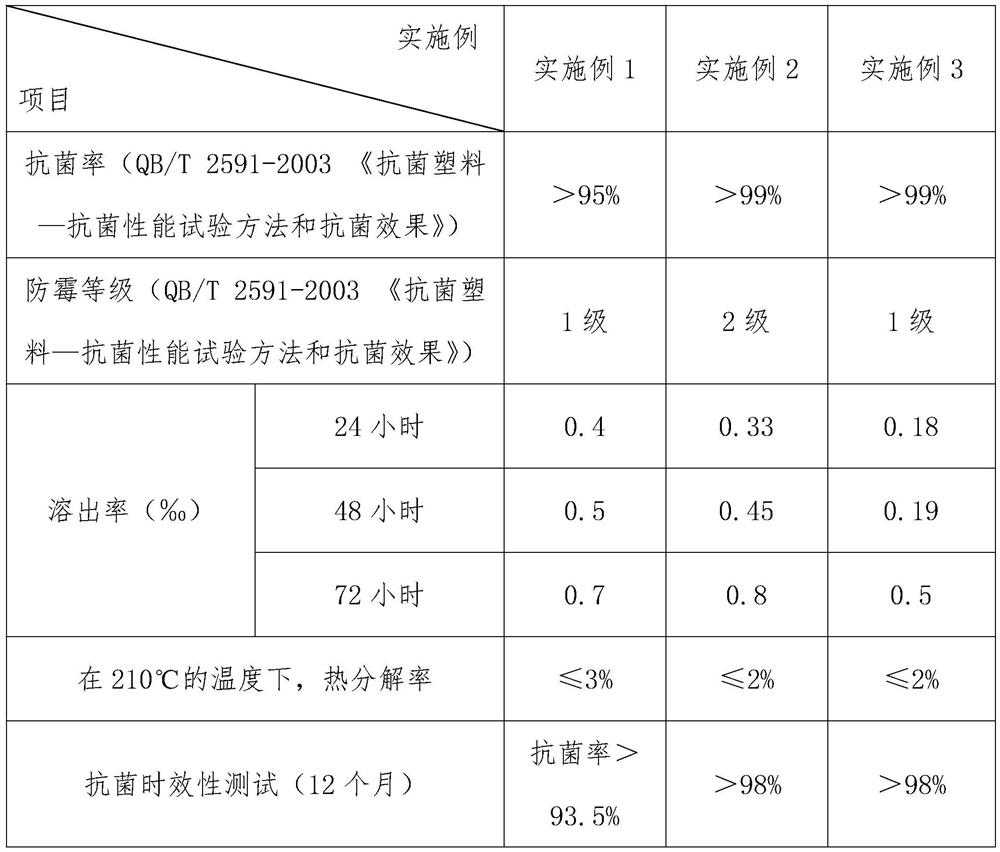

Embodiment 1

[0026] This specific embodiment is an antibacterial agent for producing modified plastics, which includes the following components in parts by weight: 10 parts of zeolite, 20 parts of glass, 15 parts of zirconium phosphate, 30 parts of ceramics, 20 parts of bentonite, natural 10 parts of antibacterial compound, 8 parts of 2-carboxy-4-methoxybenzophenone, 30 parts of compound ion solution, 6 parts of quaternary ammonium salt, 5 parts of coupling agent, and 5 parts of compound anti-mold additive.

[0027] Preferably, the compound ion solution contains soluble silver salt solution, soluble copper salt solution, and soluble zinc salt solution, and the volume ratio of soluble silver salt solution, soluble copper salt solution, and soluble zinc salt solution is 15:5:5.

[0028] Preferably, the natural antibacterial compound contains 5 parts by weight of chitin, 5 parts by weight of mustard, 5 parts by weight of castor oil and 5 parts by weight of wasabi.

[0029] Preferably, the com...

Embodiment 2

[0040] This specific embodiment is an antibacterial agent for producing modified plastics, which includes the following components by weight: 30 parts of zeolite, 20 parts of glass, 20 parts of zirconium phosphate, 10 parts of ceramics, 15 parts of bentonite, natural 15 parts of antibacterial compound, 10 parts of 2-carboxy-4-methoxybenzophenone, 20 parts of compound ion solution, 8 parts of quaternary ammonium salt, 8 parts of coupling agent, and 3 parts of compound anti-mold additive.

[0041] Preferably, the compound ion solution contains soluble silver salt solution, soluble copper salt solution, and soluble zinc salt solution, and the volume ratio of soluble silver salt solution, soluble copper salt solution, and soluble zinc salt solution is 15:5:5.

[0042] Preferably, the natural antibacterial compound contains 5 parts by weight of chitin, 4 parts by weight of mustard, 4 parts by weight of castor oil and 4 parts by weight of wasabi.

[0043] Preferably, the composite a...

Embodiment 3

[0054] This specific embodiment is an antibacterial agent for producing modified plastics. The antibacterial agent includes the following components in parts by weight: 30 parts of zeolite, 10 parts of glass, 10 parts of zirconium phosphate, 20 parts of ceramics, 30 parts of bentonite, natural 15 parts of antibacterial compound, 8 parts of 2-carboxy-4-methoxybenzophenone, 30 parts of compound ion solution, 8 parts of quaternary ammonium salt, 6 parts of coupling agent, and 5 parts of compound anti-mold additive.

[0055] Preferably, the compound ion solution contains soluble silver salt solution, soluble copper salt solution, and soluble zinc salt solution, and the volume ratio of soluble silver salt solution, soluble copper salt solution, and soluble zinc salt solution is 15:5:5.

[0056] Preferably, the natural antibacterial compound contains 5 parts by weight of chitin, 5 parts by weight of mustard, 5 parts by weight of castor oil and 5 parts by weight of wasabi.

[0057] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com