Preparation method for improving polymerization temperature of polyisomonoolefin-based elastomer or molecular weight of elastomer

A polymerization temperature and high molecular weight technology, applied in the field of polymer compound preparation, can solve the problems of butyl rubber molecular chain branching and poor product performance, so as to increase the polymerization reaction temperature, slow down the polymerization rate, and reduce the consumption of volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

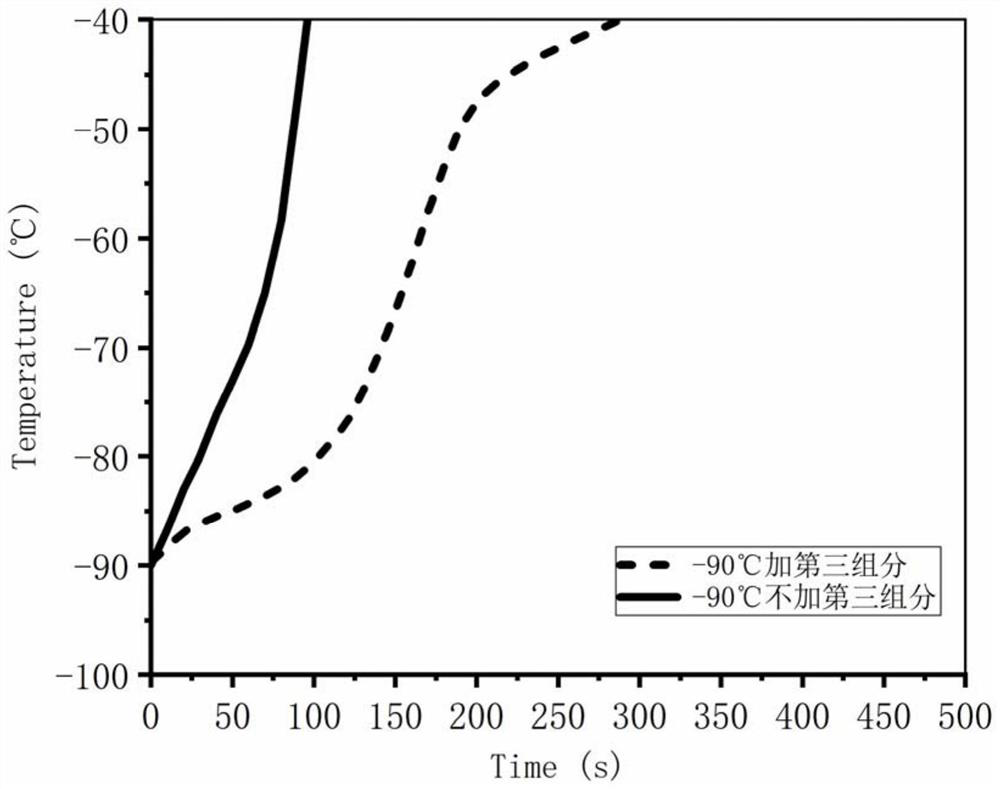

[0058] A 4-liter low-temperature polymerization kettle was used, which was baked, vacuumed, and nitrogen-filled, then cooled to -90°C, and 1300 g of dichloromethane, 540 g of isobutylene, and 16 g of isoprene were added. Add 0.01M aqueous solution as the main initiator, 0.1M trichlorotriethyl dialuminum as the co-initiator, mix and configure the initiation system, and then press nitrogen into the reactor to initiate polymerization, and finally add a small amount of methanol to terminate the reaction, and then the product The solvent was removed and dried to constant weight.

Embodiment 2

[0060] A 4-liter low-temperature polymerization kettle was used, which was baked, vacuumed, and nitrogen-filled, then cooled to -90°C, and 1300 g of dichloromethane, 540 g of isobutylene, 16 g of isoprene, and 5 g of the third component, methyl benzoate, were added. Add 0.01M aqueous solution as the main initiator, 0.1M trichlorotriethyl dialuminum as the co-initiator, mix and configure the initiation system, and then press nitrogen into the reactor to initiate polymerization, and finally add a small amount of methanol to terminate the reaction, and then the product The solvent was removed and dried to constant weight.

Embodiment 3

[0062] A 4-liter low-temperature polymerization kettle was used, and after baking, vacuuming, and filling with nitrogen, it was cooled to -80°C, and 1300 g of methylene chloride, 540 g of isobutylene, and 16 g of p-methylstyrene were added. Add 0.01M aqueous solution as the main initiator, 0.15M aluminum chloride as the co-initiator, mix and configure the initiation system, then press nitrogen into the reactor to initiate polymerization, and finally add a small amount of methanol to terminate the reaction, and then remove the solvent from the product , dried to constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com