Ultra-high performance concrete containing smelting slag and preparation method thereof

An ultra-high performance, smelting slag technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high cost of ultra-high performance concrete, high environmental protection cost and energy consumption rate, and achieve Avoid electrochemical reactions, promote the formation of early strength, and improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

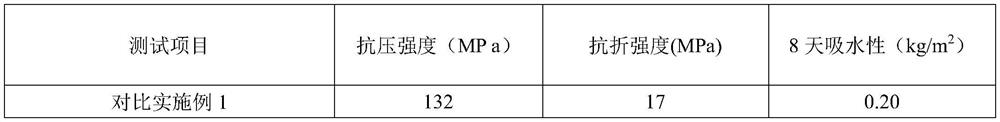

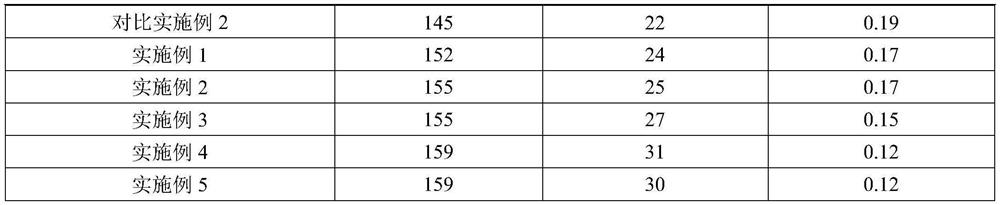

[0036] Example 1: A kind of ultra-high performance concrete containing smelting slag and its preparation method

[0037] The ultra-high performance concrete containing smelting slag provided in this example includes the following components in parts by weight: 664 parts of cement, 51 parts of silica fume, 204 parts of fly ash, 102 parts of slag powder, and 156 parts of modified steel fiber 184 parts of water, 594 parts of quartz sand and 594 parts of ferrochrome slag.

[0038] Its preparation method comprises the following steps:

[0039] S1, uniformly mix cement, silica fume, fly ash and slag powder;

[0040] S2, adding water to step S1, stirring to form a mixture;

[0041] S3, add quartz sand and ferrochrome slag in step S2, stir evenly;

[0042] S4. Add modified steel fibers to step S3, and stir evenly.

Embodiment 2

[0043] Example 2: A kind of ultra-high performance concrete containing smelting slag and its preparation method

[0044] The ultra-high performance concrete containing smelting slag provided in this example includes the following components in parts by weight: 664 parts of cement, 51 parts of silica fume, 204 parts of fly ash, 102 parts of slag powder, and 156 parts of modified steel fiber 184 parts of water, 891 parts of quartz sand and 297 parts of ferrochrome slag.

[0045] Its preparation method comprises the following steps:

[0046] S1, uniformly mix cement, silica fume, fly ash and slag powder;

[0047] S2, adding water to step S1, stirring to form a mixture;

[0048]S3, add quartz sand and ferrochrome slag in step S2, stir evenly;

[0049] S4. Add modified steel fibers to step S3, and stir evenly.

Embodiment 3

[0050] Example 3: A kind of ultra-high performance concrete containing smelting slag and its preparation method

[0051] The ultra-high performance concrete containing smelting slag provided in this example includes the following components in parts by weight: 664 parts of cement, 51 parts of silica fume, 204 parts of fly ash, 102 parts of slag powder, and 156 parts of modified steel fiber 184 parts of water, 309 parts of quartz sand and 891 parts of ferrochrome slag.

[0052] Its preparation method comprises the following steps:

[0053] S1, uniformly mix cement, silica fume, fly ash and slag powder;

[0054] S2, adding water to step S1, stirring to form a mixture;

[0055] S3, add quartz sand and ferrochrome slag in step S2, stir evenly;

[0056] S4. Add modified steel fibers to step S3, and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com