Iron phosphate dihydrate and preparation method thereof, iron phosphate, lithium iron phosphate and lithium ion battery

A technology of ferric phosphate dihydrate and ferric phosphate, which is applied in secondary batteries, chemical instruments and methods, circuits, etc., can solve the problems of high cost and low purity of ferric phosphate, and achieve low cost, good lithium battery performance and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

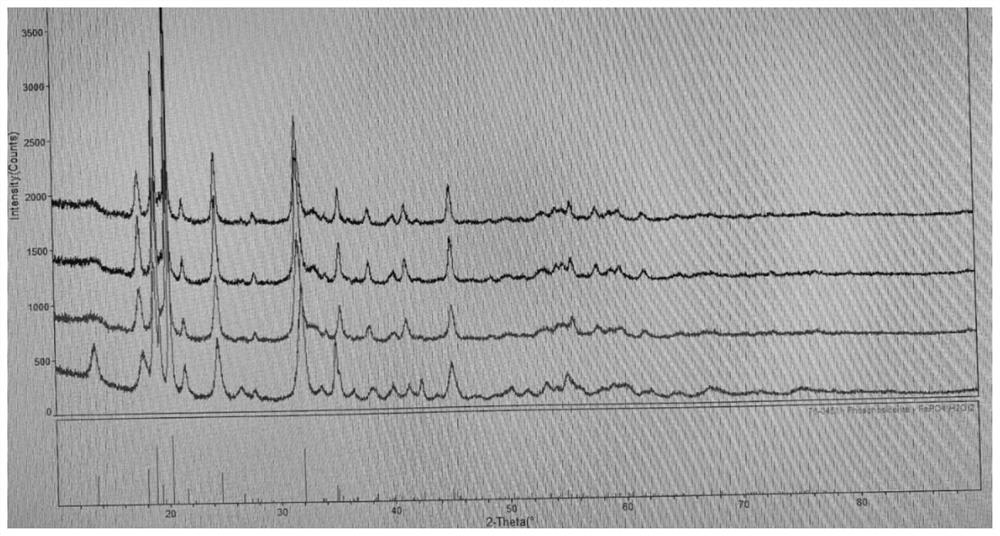

[0039] This application provides a preparation method of ferric phosphate dihydrate, please refer to figure 1 ,include:

[0040] S10: Using pyrite slag as a raw material to perform acid leaching to remove impurities to obtain an acid leaching solution.

[0041] Specifically, pyrite slag is the residue of sulfuric acid produced by pyrite, and is one of the main industrial solid wastes in my country. It is mainly used to make cement, bricks, etc. Pyrite slag contains a large amount of iron source, so it can be used as Free iron source, using pyrite slag as raw material can reduce the cost. The iron source in the pyrite slag can be dissolved by acid leaching, and the undissolved impurities can be removed by filtration. The reaction formula is as follows:

[0042] Fe 2 o 3 +6H + =2Fe 3+ +3H 2 O.

[0043] Preferably, the acid leaching and impurity removal by using the pyrite slag as raw material to obtain the acid leaching solution includes:

[0044] Take pyrite slag, add s...

Embodiment 1

[0079] Embodiment 1 prepares the concrete steps of ferric phosphate dihydrate as follows:

[0080] a. Acid leaching to remove impurities: Take pyrite slag, add sulfuric acid for acid leaching, the acid concentration is 3mol / L, the amount added is 2 times the molar mass of iron, the acid leaching temperature is 60 degrees, and the acid leaching is completed and filtered to remove Acid insoluble matter, to obtain pickling solution.

[0081] b. Precipitation and impurity removal: add lye to the pickling solution to adjust the pH to 3.3, so that the ferric hydroxide is completely precipitated and the impurity ions remain in the filtrate. The acid solution was filtered to obtain ferric hydroxide, and the filter cake was washed with water to pH 9.

[0082] c. Acid dissolution: add the filter cake to the phosphoric acid solution, the concentration of the phosphoric acid solution is 3mol / L, the phosphoric acid addition is 3 times the molar mass of iron, and a complexing agent is adde...

Embodiment 2

[0085] Embodiment 2 prepares the concrete steps of ferric phosphate dihydrate as follows:

[0086] a. Acid leaching to remove impurities: take pyrite slag, add hydrochloric acid for acid leaching, the acid concentration is 1mol / L, the amount added is 4 times the molar mass of iron, the acid leaching temperature is 40 degrees, and the acid leaching is completed and filtered to remove Acid insoluble matter, to obtain pickling solution.

[0087] b. Precipitation and impurity removal: add lye to the pickling solution to adjust the pH to 1.6, so that the ferric hydroxide is completely precipitated and the impurity ions remain in the filtrate. The acid solution was filtered to obtain ferric hydroxide, and the filter cake was washed with water to pH 7.

[0088] c, acid soluble: add filter cake in phosphoric acid solution, the concentration of phosphoric acid solution is 1mol / L, and the phosphoric acid addition amount is 7 times of iron molar mass, simultaneously adds complexing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com