Electric hoist with low-friction spherical hinge

An electric hoist, low-friction technology, applied in the direction of engine components, clockwork mechanism, engine lubrication, etc., can solve the problems of reducing the safety of electric hoists, reducing the shock absorption effect and service life, and ball hinge wear, etc., to achieve faster The effect of restoring stable time, reducing direct contact friction, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

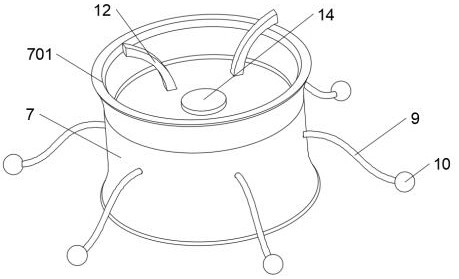

[0041] see Figure 1-5 , an electric hoist with a low-friction ball hinge, comprising an electric hoist body 1, the lower end of the electric hoist body 1 is connected with a ball hinge connecting shaft 2, and the outer end of the ball hinge connecting shaft 2 is wrapped with a hard shell tube 201, A flexible buffer hemisphere 3 is installed symmetrically and fixedly inside the ball joint connecting shaft 2, and a squeezing deformation oil storage bag 4 is fixedly connected between the two flexible buffering hemispheres 3, and the squeezing deformation oil storage bag 4 is filled with lubricating oil, and the pushing deformation The oil storage bag 4 is symmetrically installed with a primary oil delivery thick tube 5, and the end of the primary oil delivery thick tube 5 away from the squeezed and deformed oil storage bag 4 extends into the flexible buffer hemisphere 3, and the outer side of the primary oil delivery thick tube 5 A plurality of secondary oil supply thin tubes 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com