Yarn tension control method based on sliding mode fuzzy control

A yarn tension and fuzzy control technology, applied in the textile field, can solve problems such as insufficient system stability and slow speed, achieve parameter changes and disturbance insensitivity, reduce static difference, and achieve simple physical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

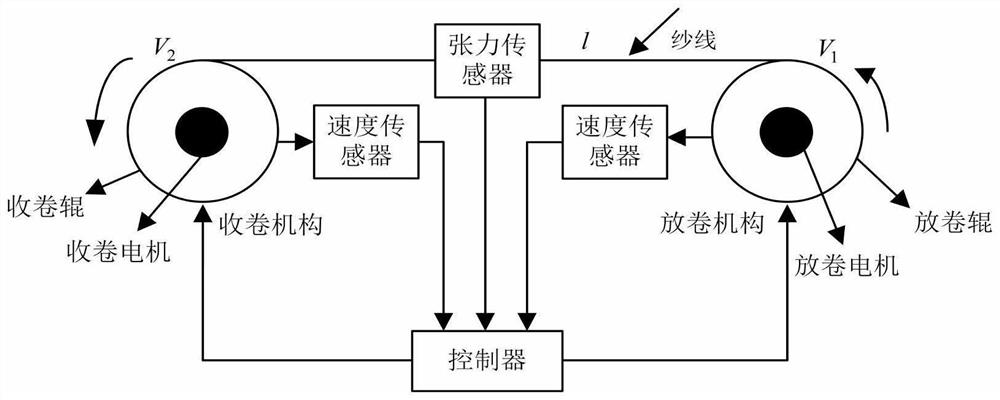

[0021] The structure of the yarn tension control system is as follows: figure 1 As shown, it consists of five parts: speed sensor, controller, tension sensor, winding mechanism and unwinding mechanism. The winding and unwinding mechanisms are respectively composed of winding and unwinding motors and winding and unwinding rollers. The winding and unwinding motors respectively drive the winding and unwinding rollers, and the winding and unwinding motors are directly connected with the winding and unwinding rollers. V 2 , V 1 Respectively, the linear speed of the take-up and unwinding rollers, l is the yarn length between the take-up and unwinding rollers. When there is a speed difference between the take-up and unwind rollers, tension is created inside the yarn. When V 2 greater than V 1 Too much will cause the yarn tension to be too large, which will easily cause the yarn to break; otherwise, the yarn tension will be too small, which will easily cause the yarn to fall off....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com