Mold preparation method, mold and railway vehicle connecting piece

A technology for molds and mold bodies, which is applied in manufacturing tools, additive manufacturing, metal processing equipment, etc., can solve the problems of low production efficiency and waste of cost, and achieve the effects of simple operation, improved production efficiency, and increased mold rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

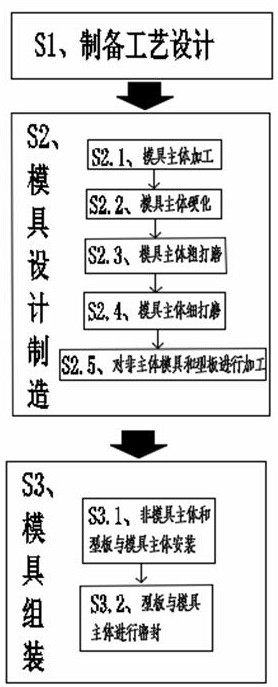

[0055] refer to Figure 1-Figure 8 , is a kind of mold preparation method disclosed by the present invention, comprises the following steps:

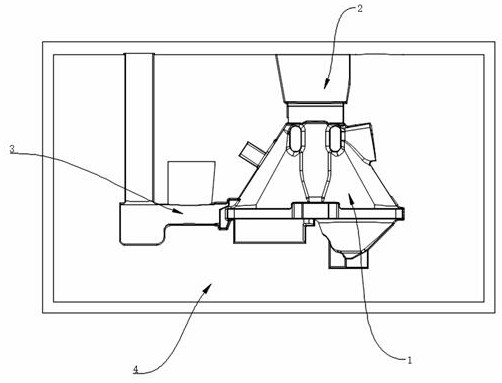

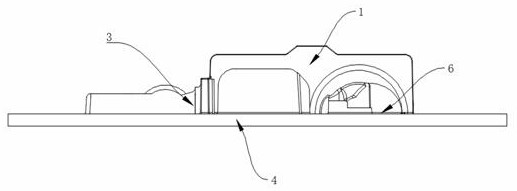

[0056] S1: Preparation process design, process design and mold design according to the shape and structure of the product, divide the mold into two parts: the mold main body and the non-main body mold, the mold main body is divided into the direct molding product surface and the structural mold part, and the non-main mold part is For the mold part of the auxiliary molding product, the non-main mold is designed in the same plane as the parting surface 6 of the mold body 1; the stereolithography molding part is selected, and the surface roughness of the product requires Ra (contour arithmetic mean deviation) ≤ 50 μm for the mold body 1 The part is molded by stereolithography mold as part 1 of the main body of the mold, and other parts (such as gate, riser 2, etc.) are molded by wood mold, which are non-main mold parts.

[0057] The desig...

Embodiment 2

[0071] refer to Figure 9 , is a rail vehicle connector disclosed in the present invention, including a mechanical coupler 20 and an electrical coupler 21, both of which are prepared by the mold in Example 1, and then quickly assembled, which is not only convenient for production, And the work efficiency is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com