Device for manufacturing mortar by using waste concrete

A waste concrete and mortar technology, applied in the direction of clay preparation device, mixing operation control device, unloading device, etc., can solve the problems that cannot meet the construction requirements, large particles of sand and sand in the mortar, achieve uniform consistency and prevent the loss of baffles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

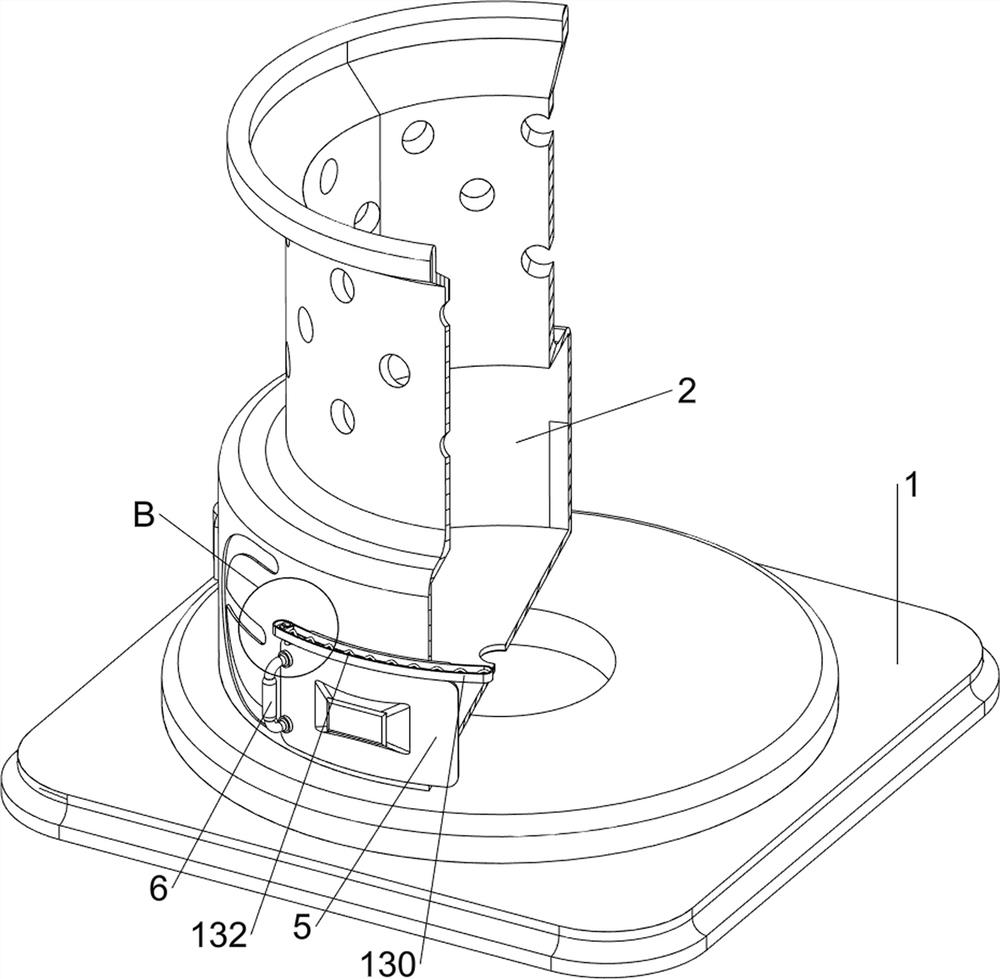

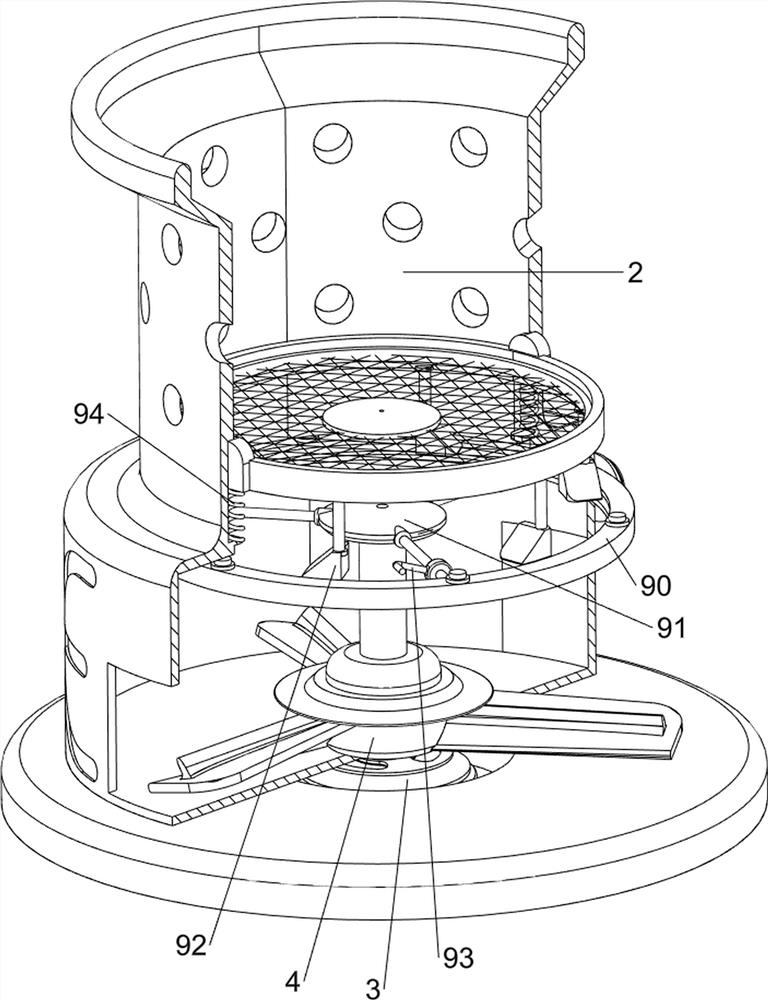

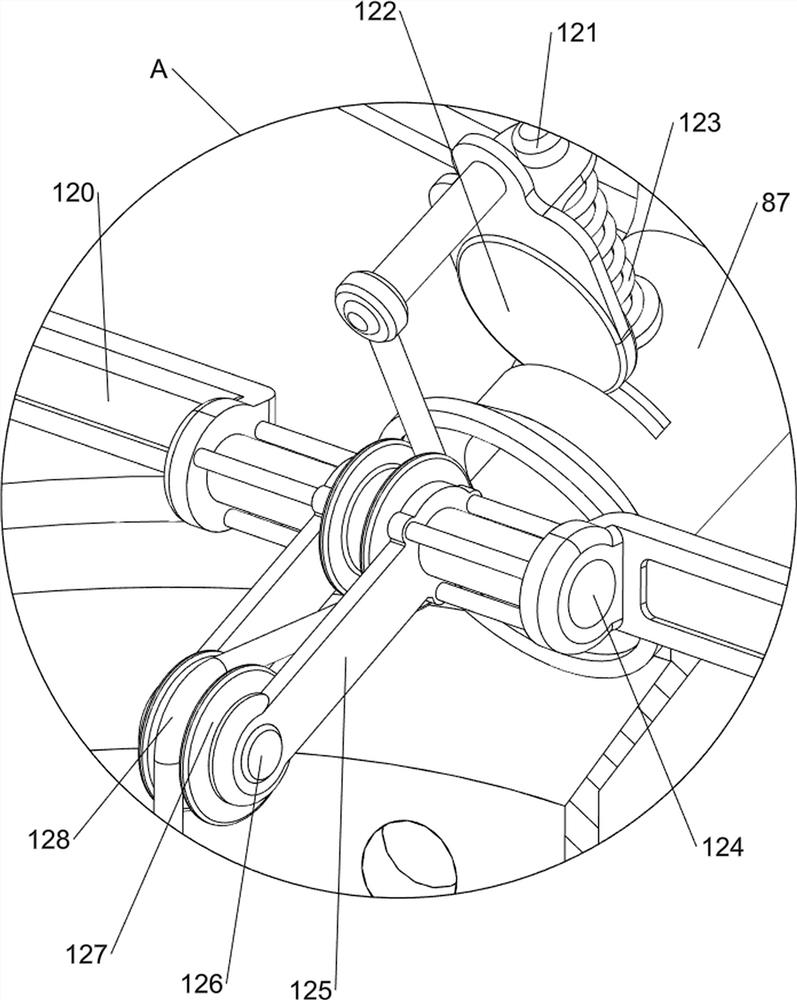

[0034] A mortar device that uses waste concrete to make mortar, such as Figure 1-5Shown, including the base plate 1, charging frame 2, the first motor 3, mixing rod 4, baffle 5, handle 6, filter 7, crushing mechanism 8 and jitter mechanism 9, the bottom plate 1 top middle is provided with a loading frame 2, the bottom plate 1 is provided with a first motor 3 in the middle, the first motor 3 output shaft is provided with a stirring rod 4, the mixing rod 4 is located inside the charging frame 2, the first motor 3 output shaft is connected to the charging frame 2 rotational type, the lower front side of the charging frame 2 is opened with a discharge port, and the sliding type on the discharge port is provided with a baffle 5. Baffle 5 front left side with handle 6, charging frame 2 inside the upper sliding type with filter 7, bottom plate 1 top with crushing mechanism 8, charging frame 2 in the middle of the jitter mechanism 9, charging frame 2 on the outside of the upper side of t...

Embodiment 2

[0041] On the basis of Example 1, e.g., Figure 1 、 Figure 6 、 Figure 7 、 Figure 8 、 Figure 9 、 Figure 10 and Figure 11 Shown, further comprising a water adding mechanism 10, the water adding mechanism 10 comprising a connecting block 100, a water collection frame 101, a water pump 102, an outlet pipe 103 and a water valve 104, two support frames 80 rear are equipped with a connection block 100, two connecting blocks 100 are connected to the rear side of the water collection frame 101, the rear of the water collection frame 101 is provided with a water pump 102, the bottom of the pump 102 is connected to the outlet pipe 103, the end of the water pipe 103 is connected to the charging box 2, Outlet pipe 103 lower side rotating type is provided with a water valve 104.

[0042] Sand soil in the filter mixing, people can pour clean water into the collection frame 101, you can start the pump 102, so that the pump 102 work will be the collection box 101 within the water pumping water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com