Tungsten oxide composite material and preparation method and application thereof

A composite material, tungsten oxide technology, applied in the field of nanomaterials, can solve the problems of hindering the reductive reaction and low photocatalytic activity, and achieve the effect of a large range of options, a variety of types, and fine particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

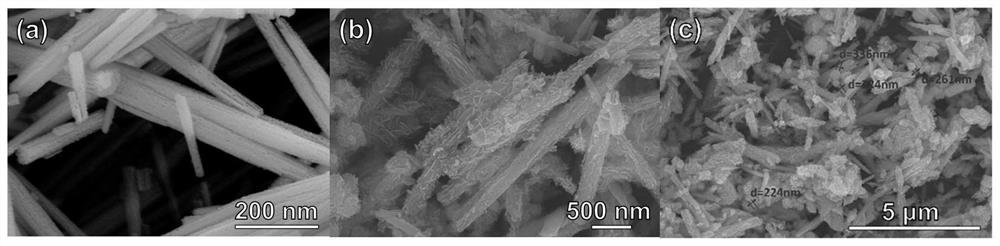

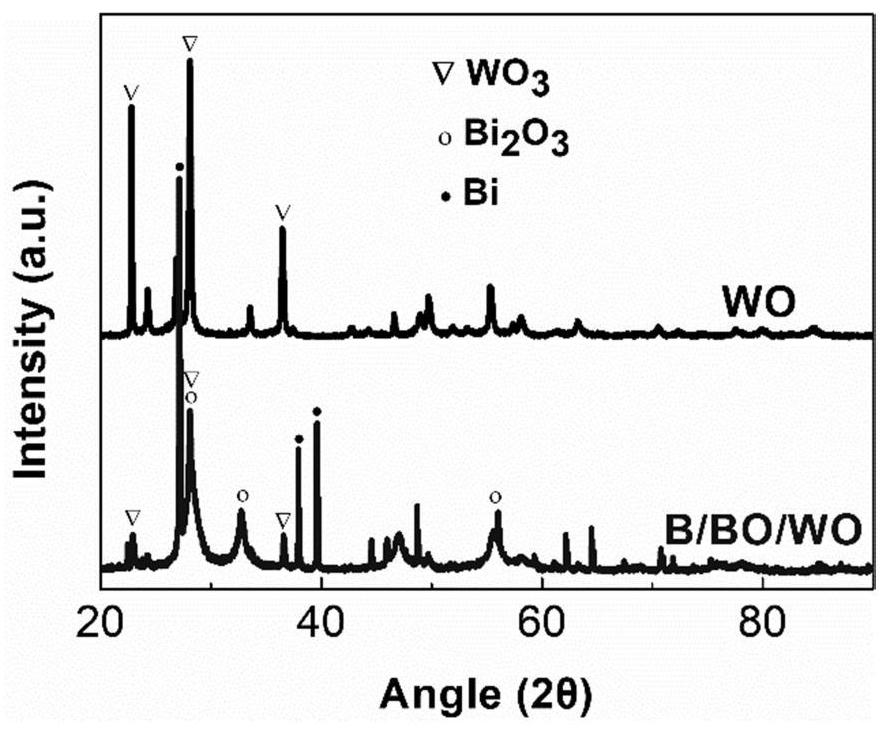

[0051] Weigh 0.0125mmol Na 2 WO 4 2H 2 O, dissolved in 90ml of pure water, fully stirred and dissolved to form solution A; weighed 0.1mol NaCl, dissolved in 20ml of pure water, fully stirred and dissolved to form solution B; solution A was continuously stirred by magnetic force, and added to solution B drop by drop , then adjust the mixed solution to pH = 2 with 2.5M HCl (aq), then put it into an autoclave, conduct a hydrothermal reaction at 180°C for 9 hours, cool to room temperature, wash with deionized water and ethanol, and centrifuge (3000r / min ) after multiple times, dry at 60°C for 12h to obtain a hydrothermal sample WO, such as figure 1 as shown in a.

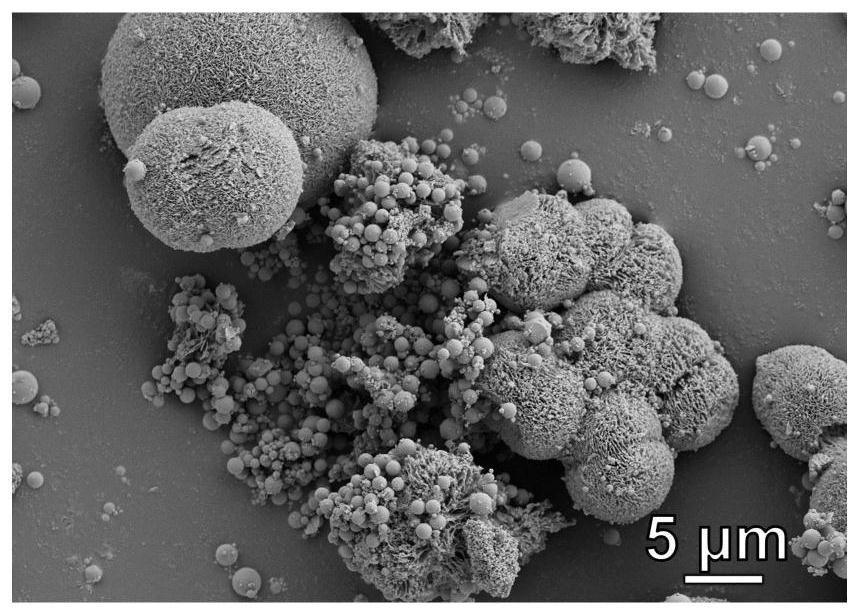

[0052] Weigh 0.003mol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 60ml of ethylene glycol, stirred at room temperature for 30 minutes, 0.12 g of EDTA was added to it, and after fully stirred at room temperature for 60 minutes, 0.7 g of WO prepared by the above-mentioned hydrothermal method was added. In the kettle, reac...

Embodiment 2

[0058] The preparation process of the composite product is the same as in Example 1. This example is mainly used to illustrate one of the dual functions of the prepared composite product—the application effect of photocatalytic degradation of organic dye MB.

[0059] Disperse 10mg of the composite product in 100ml of 10mg / L MB solution, stir for 30min under dark conditions, and reach adsorption equilibrium; then place it on a xenon lamp device (420nm filter, 20A current), and simulate MB under visible light under constant stirring During the degradation process, samples were taken at a fixed time period, and the MB content in the solution was detected after centrifugation, and the degradation efficiency of the product corresponding to a certain period of time was calculated. The final degradation effect is as Figure 5 As shown, it can be seen that the composite product has a good degradation effect on MB, reaching 95% at 210 min.

Embodiment 3

[0064] The preparation process of the composite product is the same as in Example 1, and this example is mainly used to illustrate the second dual function of the prepared composite product—the application effect of SERS detection of the organic dye MB.

[0065] Take an appropriate amount of composite products, and evenly disperse them in a concentration range of 10 -3 M-10 -8 A mixed solution is formed in the MB solution of M, and 20 μL of the mixed solution is added dropwise to 2*2cm 2 On the substrate, the SERS detection is carried out immediately after drying, and the enhancement of the Raman signal peak of the pollutant by the material is obtained under the excitation wave of 532nm. The final signal peak as Figure 7As shown, it can be seen that as the concentration of the solution decreases, the intensity of the characteristic peaks also gradually decreases until 10 -8 M, 1622 and 1395cm -1 The characteristic peaks at can still be discerned, indicating that the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com