Galvanized steel plate with visible light-responsive photocatalytic coating on surface and manufacturing method thereof

A galvanized steel sheet, surface loading technology, applied to the surface coating liquid device, chemical instruments and methods, coatings, etc., can solve problems such as galvanized steel sheet corrosion, to improve the bonding strength, eliminate haze-causing sources and High effect of VOC and post-processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

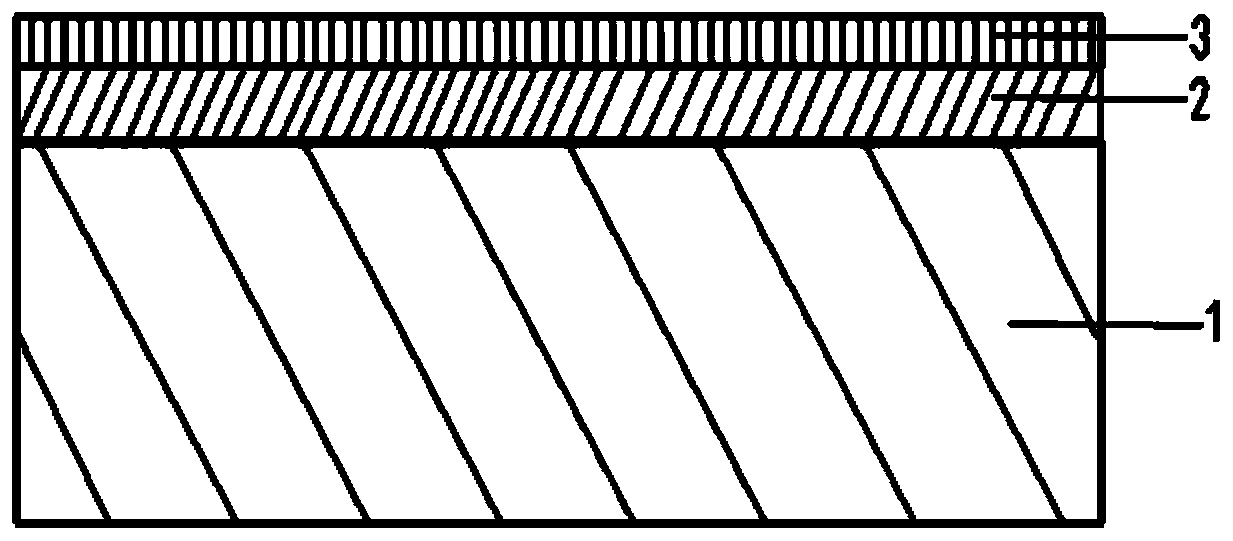

[0047] In 18 embodiments of the present embodiment and 5 comparative examples, all use hot-dip galvanized steel plate, and adopt the mode coating passivation film 2 and photocatalytic coating 3 on its surface by roller coating.

Embodiment 1-1

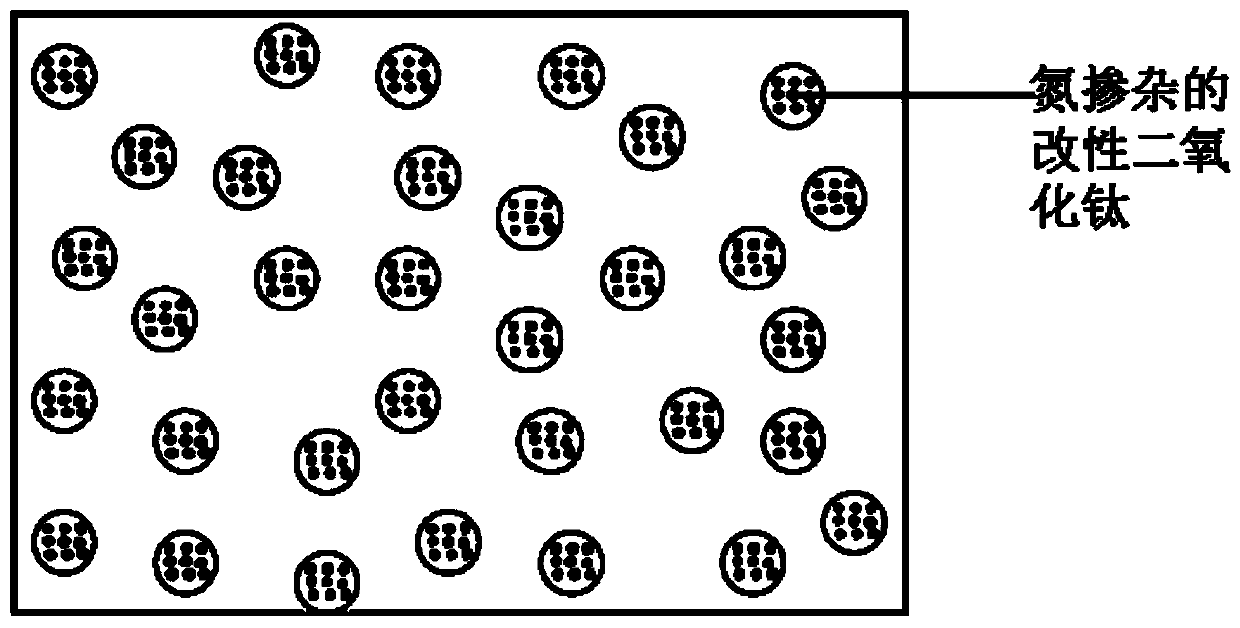

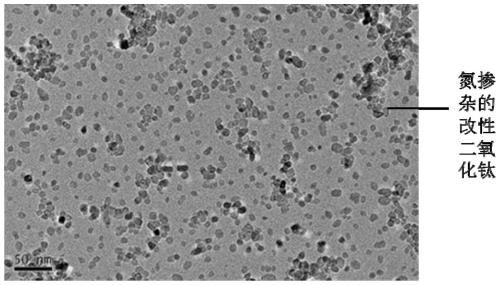

[0049] like figure 1 and figure 2 as shown,

[0050] In this embodiment, a hot-dip pure galvanized steel sheet with a thickness of 0.8 mm (zinc adhesion is 60 g / m2) is used, and its surface roughness Ra is (0.8-1.2) microns.

[0051] At first on the galvanized steel sheet 1, adopt the method for vertical roller coating, with the technology that coating roll speed ratio 160%, take-up roll speed ratio 35%, take-off roll and coating roll pressure 4.0KN will solid content be 20 % (calculated as zirconate, the balance being fluoride, phosphoric acid and water) chemical passivation treatment solution is coated on the surface of galvanized steel sheet 1, and phosphoric acid in the chemical treatment solution reacts with the zinc layer, reducing the pH of the treatment solution At the same time, the generated zinc ions and zirconate together form a hydrated complex, heated at 400°C for 10 seconds, and after the water is volatilized, a passivation layer with an adhesion amount of 70...

Embodiment 2

[0057] In 9 examples of present embodiment, all use hot-dip galvanized steel plate, and adopt the mode of roller coating to coat passivation film 2 and photocatalytic coating 3 on its surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com