High-robustness lotus-leaf-imitating structure super-hydrophobic coating as well as preparation method and application thereof

A super-hydrophobic coating and high-robust technology, applied in the field of super-hydrophobic coating with high-robust imitation lotus leaf structure and its preparation, can solve the problems of insufficient air layer stability and insufficient super-hydrophobic microstructure, etc. To achieve the effect of efficient and fast process, simple and easy preparation method, and high robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a preparation method of a high robustness imitation lotus leaf structure super-hydrophobic coating, comprising the following steps:

[0036] S1: Disperse the nanoparticles in a fluorosilane solution, adjust the pH to 4-6 with an acidic aqueous solution to hydrolyze the fluorosilane, and heat and stir to fully react the fluorosilane and the nanoparticles to obtain hydrophobic nanoparticles.

[0037] Step S1 is to hydrophobically modify the nanoparticles.

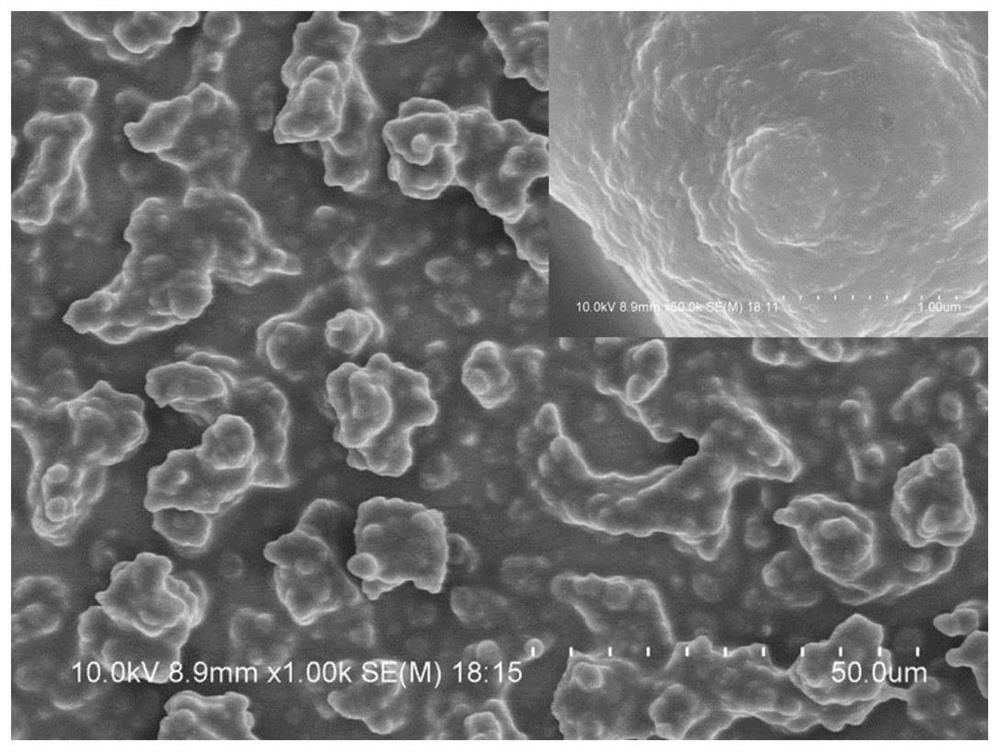

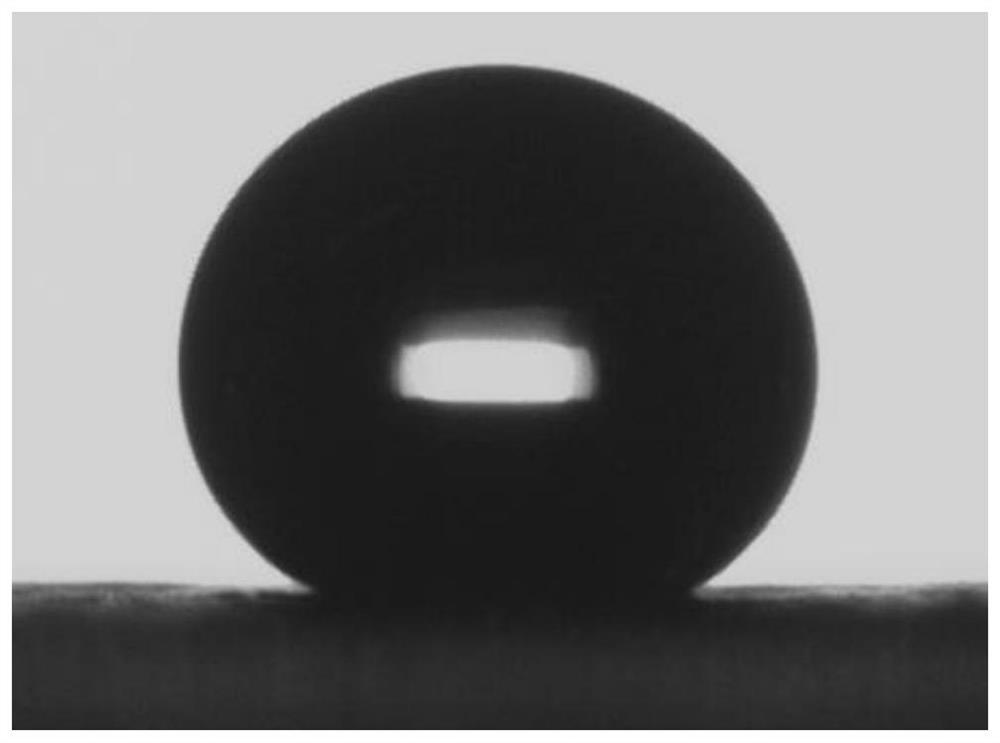

[0038] Preferably, the particle size of the nanoparticles is 4-500 nm, so as to facilitate the construction of a micro-nano hierarchical structure. If the particles are too small, the cost is too high, the particles are too large, and it is difficult to disperse into small droplets with a size smaller than that of air spray droplets, and the ideal structure cannot be obtained.

[0039] Preferably, the nanoparticles are at least one of aluminum oxide, iron tetroxide, zinc oxide, ceria, ti...

Embodiment 1

[0056] The present embodiment provides a method for preparing a highly robust imitation lotus leaf structure super-hydrophobic coating, comprising the following steps:

[0057] S1: Hydrophobic epoxy resin is obtained by hydrophobically modifying E-51 epoxy resin by the method described in patent CN 109836557 A.

[0058] Disperse 1 g of silica nanoparticles in an ethanol solution of fluorosilane, add 50% acetic acid aqueous solution to adjust the pH to 4-6, and stir at 60° C. for 2 hours to obtain hydrophobic silica particles.

[0059] S2: Disperse 2 g of hydrophobic epoxy resin, 0.68 g of D230 curing agent, and 1 g of hydrophobic silica particles in 50 g of ethyl acetate solution, and fully stir with a magnetic stirrer for 10 min to uniformly mix the components to obtain a mixed solution.

[0060] S3: Put the above mixed solution in a 10mL syringe, use a 22G needle through an electrospinning device, set the advancing speed to 0.2mm / h, and adjust the voltage to 18kV so that the...

Embodiment 2~7

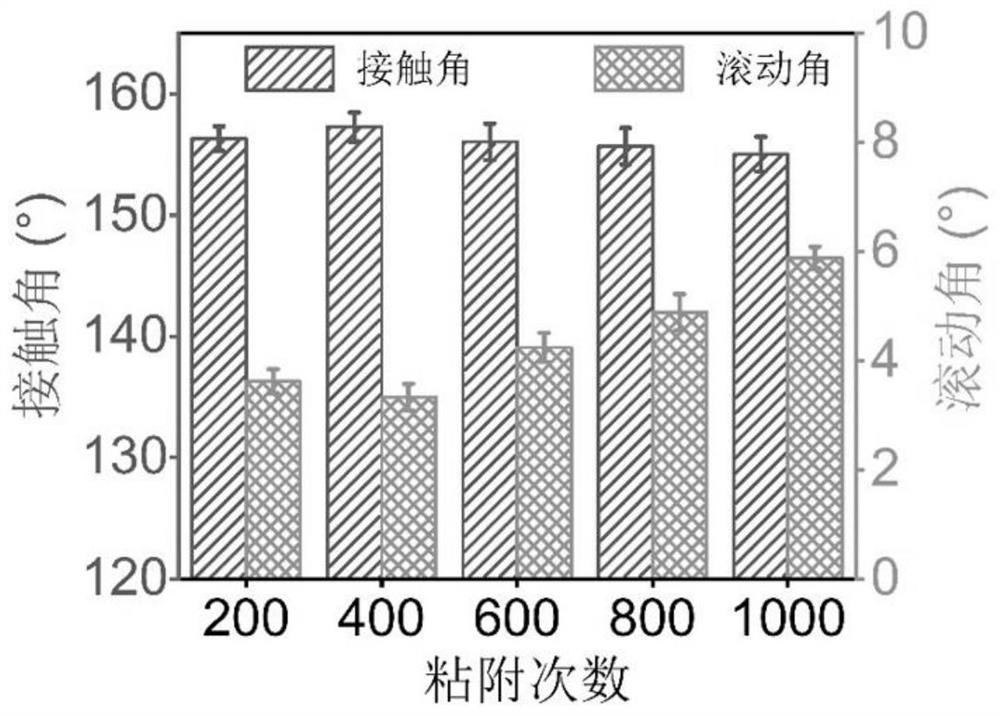

[0066] The preparation process of the present invention mainly lies in the regulation of the size of the spray droplets and the evaporation rate of the organic solvent.

[0067] This embodiment provides a preparation method of a highly robust imitation lotus leaf structure superhydrophobic coating. The process parameters and the contact angle of the prepared samples are shown in Table 1, and other preparation processes are the same as those in Embodiment 1.

[0068] The process parameters have a significant effect on the droplet state and deposition process, among which the voltage, humidity and the concentration of hydrophobic particles have a significant effect on the deposition effect. From the comparison of Examples 1 to 7, it can be seen that the voltage must reach a certain intensity in order to achieve a good atomization effect. From Examples 1 to 3, it can be seen that the lower the voltage, the worse the atomization effect, and the larger the atomized droplets, result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com