Hydraulic station with cooling system

A technology of hydraulic station and hydraulic oil tank, applied in the field of hydraulic system, can solve the problems of low efficiency, poor cooling effect of oil temperature, unfavorable cooling of hydraulic oil, etc., so as to increase cooling efficiency, improve heat exchange efficiency, and increase heat The effect of swapping areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

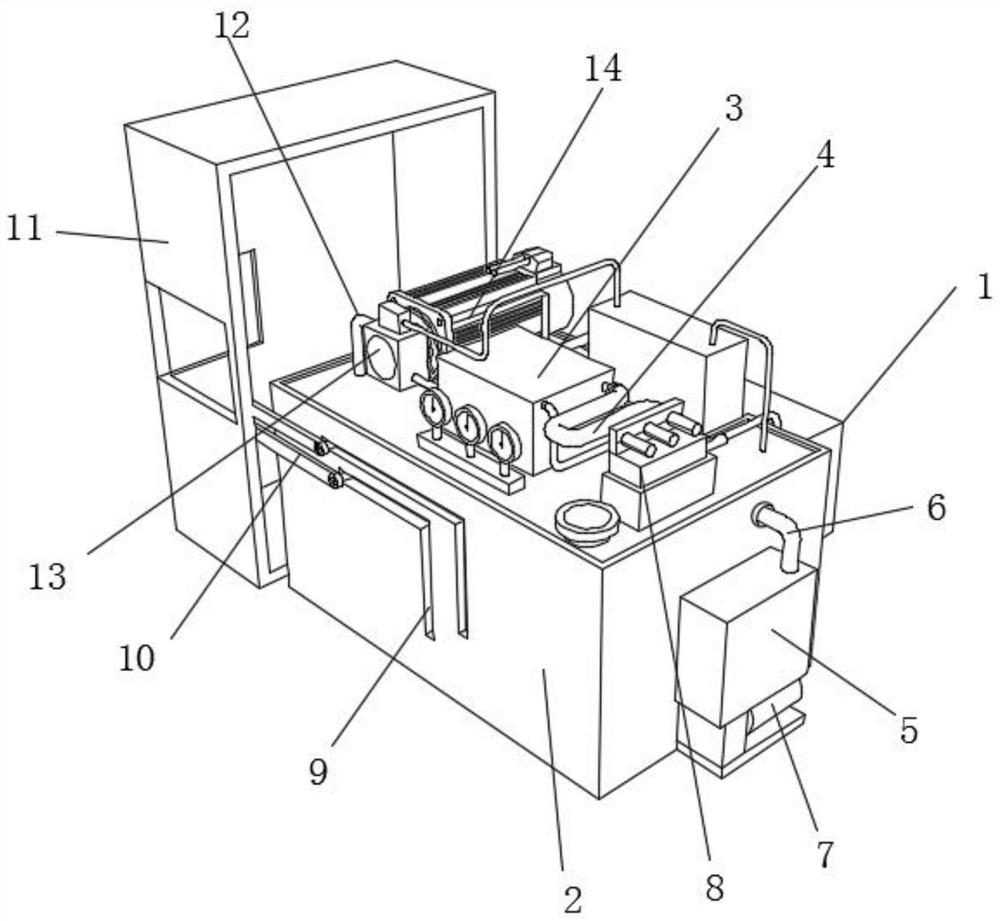

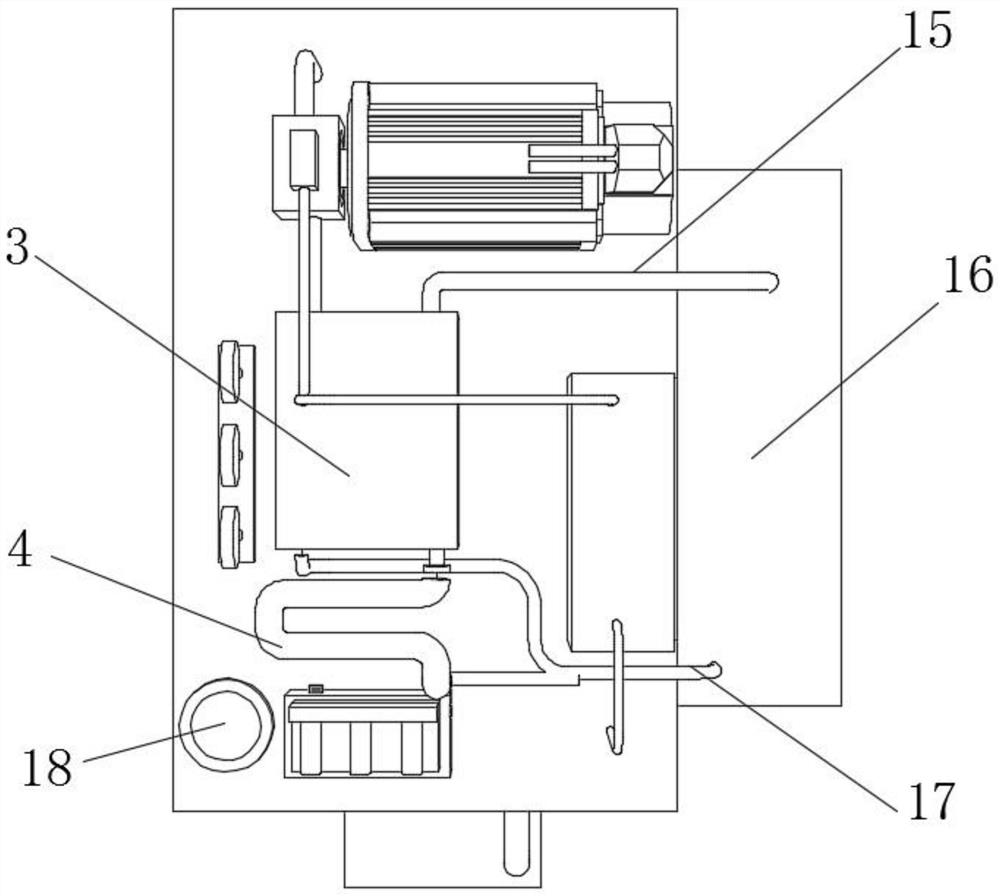

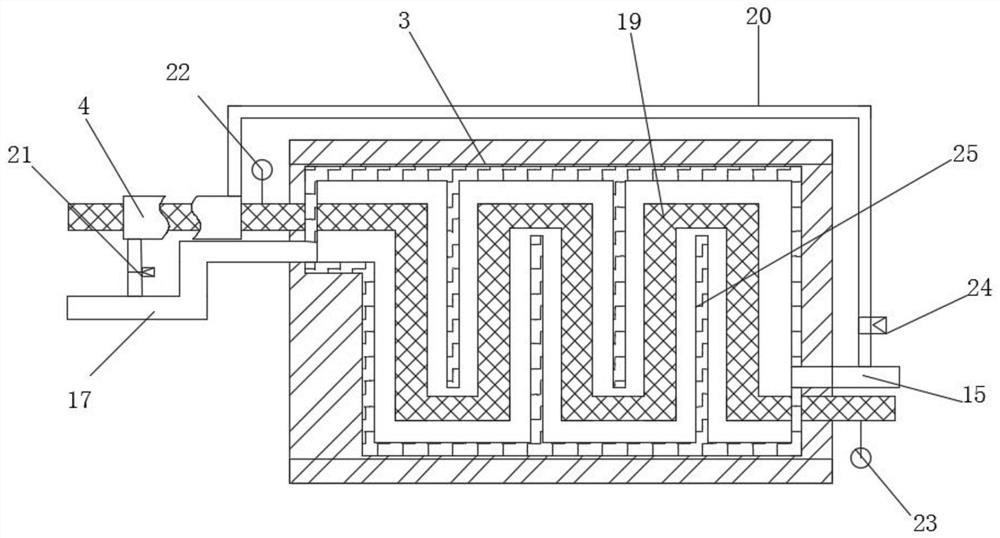

[0038] Such as Figure 1-7 As shown, the present invention provides a hydraulic station with a cooling system, including a main body device 1, a hydraulic oil tank 2 is arranged inside the main body device 1, a cooling chamber 3 is fixedly connected to the upper surface of the hydraulic oil tank 2, and the right side of the hydraulic oil tank 2 The side is provided with an external circulating filter assembly 5, the left side of the hydraulic oil tank 2 is provided with a noise reduction protective cover 11, the inner wall of the cooling chamber 3 is movably connected with an oil delivery pipe 19, and the outer wall of the left end of the oil delivery pipe 19 is provided with an auxiliary cooling pipe 4, the cooling chamber 3 The inner wall of the cooling chamber 3 is fixedly connected with a built-in partition 25, the right side of the cooling chamber 3 is fixedly connected with a refrigerant inlet pipe 15, the left side of the cooling chamber 3 is fixedly connected with a ref...

Embodiment 2

[0045] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer wall of the filter extraction pipe 29 is fixedly connected with an auxiliary filter inlet pipe 32, and the auxiliary filter inlet pipe 32 is movable away from one end of the filter extraction pipe 29 Connected with a first filter core 36, the top of the first filter core 36 is movably connected with an auxiliary filter delivery pipe 33, the outer wall of the auxiliary filter delivery pipe 33 is fixedly connected with a second electromagnetic control valve 35, and the outer wall of the auxiliary filter inlet pipe 32 A first electromagnetic control valve 34 is fixedly connected, a filter pump 7 is fixedly connected to the tail end of the filter extraction pipe 29 , and a first pressure detector 30 is fixedly connected to the outer wall of one end of the filter extraction pipe 29 .

[0046] The inner wall of the noise-reducing protective co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com