Wind power generation device

A technology for wind power generation devices and generators, applied to wind power generation, wind power engines, wind power motor combinations, etc., can solve the problems of high installation location requirements, limited application range, high wind direction requirements, etc., to improve power generation efficiency, wide application range, Good use of wind energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

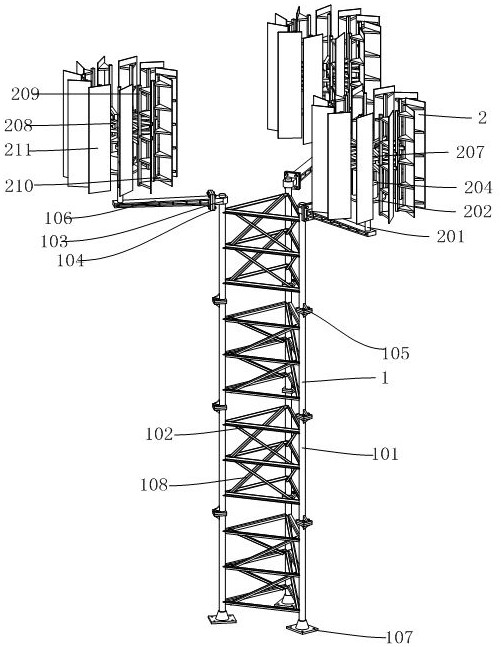

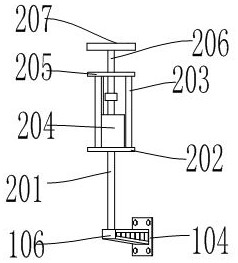

[0045] see Figure 1-Figure 4 , the present invention provides a wind power generation device, comprising a support mechanism 1 and three power generation mechanisms 2, the support mechanism 1 includes a column 101, a beam 102, and a support beam 106, the number of columns 101 is at least three and is evenly distributed in a triangle, three Each column 101 corresponds to three generators 2 respectively, and the beam 102 is horizontally fixed between the adjacent columns 101. Three support beams 106 are fixed on the top of the column 101. Each generator 2 includes a support rod 201, a generator support 202, Support column 203, generator 204, rotating shaft support 205, rotating shaft 206, support support 207, support 208, connecting rod 209, blade 211, support rod 201 is welded on one side of the top of support beam 106, and power generator is welded on the top of support rod 201. The machine support 202, the top surface of the generator support 202 is evenly welded with three ...

Embodiment 2

[0056] see Figure 5 , the second embodiment is basically the same as the first embodiment, the difference is that a central rod 109 is arranged between the three uprights 101, and a triangular plate 110 is fixed on the central rod 109, and the three ends of the triangular plate 110 are respectively fixed with three beams 102 , thus further improving the strength of the support mechanism 1 . A first reinforcement rod 111 is fixed between the beam 102 and the support beam 106, a second reinforcement rod 112 is fixed between the first reinforcement rod 111 and the support beam 106, and a third reinforcement rod 112 is fixed between the two second reinforcement rods 112. The rod 113 further improves the structural strength of the support beam 106 and the column 101, increases the stability, and prevents the generator mechanism 2 from shaking.

Embodiment 3

[0058] see Figure 6 The third embodiment is basically the same as the first embodiment, except that the shape of the blades 211 is arc-shaped, which increases the contact area with the wind, facilitates the rotation, and improves the power generation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com