Bismuth-containing compound, preparation method and application

A technology of bismuth compounds and polymer compounds, which is applied in the fields of bismuth organic compounds, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of few types of light extraction layers and unfavorable processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

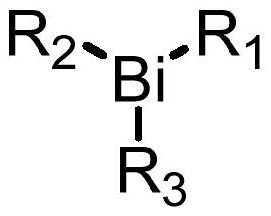

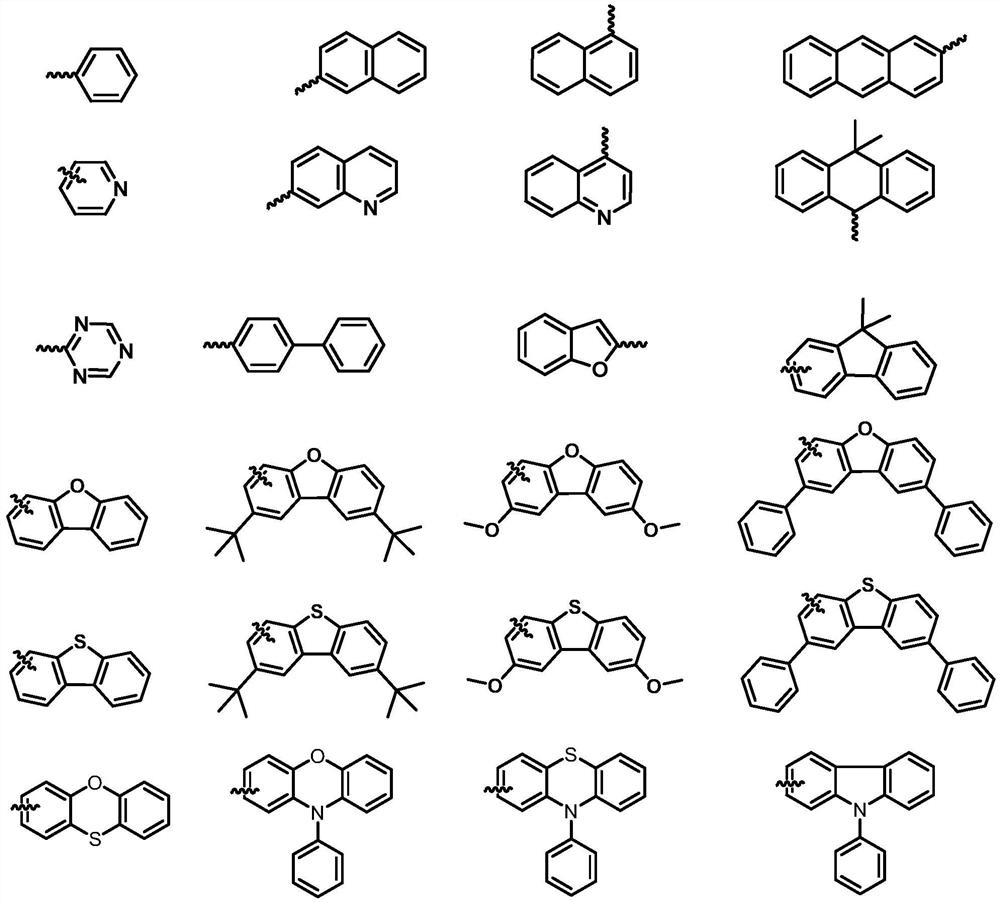

[0044] Embodiment 1 (synthesis of symmetrically substituted compounds):

[0045]

[0046] Under an inert gas protective atmosphere, dissolve 1.57g bromobenzene into 60ml anhydrous THF, add two grains of iodine, 2.16g fresh magnesium chips, heat to initiate the reaction, and slowly add 7.85g bromobenzene, heat to reflux for 2h, cool, Take 6.3g BiCl 3 Dissolved in 20mlTHF and added to Grignard reagent, stirred overnight. The reaction was quenched by adding water, extracted, concentrated and purified by column chromatography to obtain 5.2 g of white solid with a yield of 59%. The refractive index is 1.82.

[0047] For the synthesis of asymmetric bismuth compounds, the ratio of Grignard reagents can be changed to synthesize the product.

Embodiment 2

[0048] Embodiment 2 (synthesis of asymmetrically substituted compounds):

[0049]

[0050] Under an inert gas atmosphere, dissolve 1.57g of bromobenzene into 60ml of anhydrous THF, add two grains of iodine and 2.16g of fresh magnesium chips, heat to initiate the reaction, and slowly add 7.85g of bromobenzene, heat to reflux for 2h, cool, Take 9.45g BiCl 3 Dissolved in 20mlTHF and added to Grignard reagent, stirred overnight. The reaction was quenched by adding water, extracted, concentrated and purified by column chromatography to obtain 7.2 g of white solid with a yield of 60.3%.

[0051] Under an inert gas protective atmosphere, dissolve 0.5g of bromonaphthalene in 30ml of anhydrous THF, add two grains of iodine, 0.36g of fresh magnesium chips, heat to initiate the reaction, and slowly add 1.56g of bromobenzene, heat to reflux for 2h, cool, Take 3.98g of diphenylbismuth chloride dissolved in 10ml of THF and add to the Grignard reagent, and stir the reaction overnight. ...

Embodiment 3

[0052] Embodiment 3 (synthesis of condensed ring compounds):

[0053]

[0054] Under anhydrous and oxygen-free nitrogen atmosphere, take 1.38g of reaction materials and dissolve in 100ml of tetrahydrofuran, cool down to -78°C, add n-BuLi 24ml (2.5M) dropwise to it, after the dropwise addition, the reaction system is heated and refluxed for 3h , the temperature was lowered to -78°C again, and 1.335 g of bismuth tribromide was added. Raise to room temperature, stir for 1 h, cool down to 0°C, add 10.3 g of diisopropylethylamine, and heat to reflux overnight. Cooled, quenched with water, extracted with chloroform, concentrated, and purified by column chromatography to obtain 0.52 g of a yellow solid with a yield of 30.1%. The refractive index is 1.91.

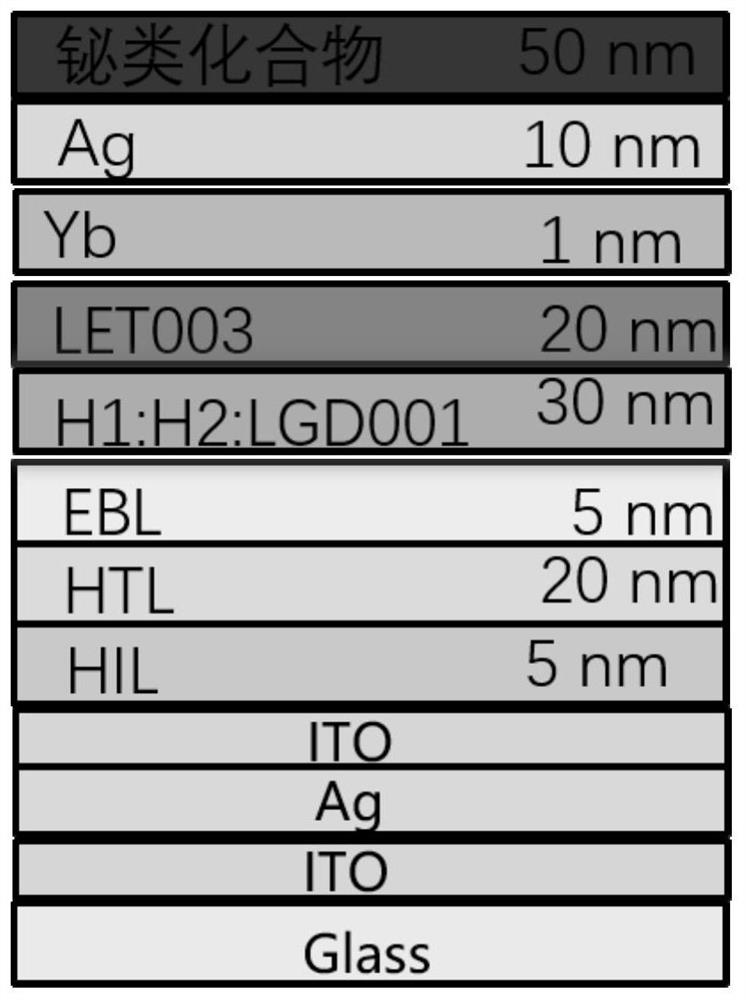

[0055] The bismuth-containing compound we prepared was used to prepare top-emitting devices, and the device structure is as follows figure 1 As shown, the device performance is shown in the table below:

[0056] ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com