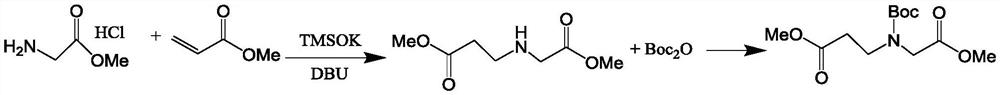

Preparation method of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-methyl propionate and intermediate of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-methyl propionate

A technology of methoxycarbonylmethyl and tert-butoxycarbonyl, applied in the field of compound synthesis, can solve the problem of low yield and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation method of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-propionic acid methyl ester of the present embodiment comprises the following steps: take a dry 250mL three-necked bottle, and add 12.6g of glycine methyl ester salt acid salt, add 252mL of methanol, start stirring, add 2.6g of TMSOK and 15.2g of DBU, then slowly add 25.8g of methyl acrylate dropwise, after the addition, it rises to 40°C, and after 1h of reaction, it drops to 25°C ℃, add 21.8g of Boc anhydride, stir at 25℃ for 2h, stop the reaction, concentrate to dryness, add 100mL of water, dissolve and extract three times with dichloromethane, combine the organic phase, wash the organic phase with saturated brine once, and then Dry over anhydrous sodium sulfate and concentrate to dryness to obtain 26.4 g of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-propionic acid methyl ester, 3-(tert-butoxycarbonyl-methoxy The yield of carbonylmethyl-amino)-propionic acid methyl ester is 96%, and...

Embodiment 2

[0023] The preparation method of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-propionic acid methyl ester of the present embodiment comprises the following steps: take a dry 250mL three-necked bottle, and add 12.6g of glycine methyl ester salt salt, add 252mL of methanol, start stirring, place the reaction bottle in an ice-water bath, add 2.6g of TMSOK and 15.2g of DBU, then slowly add 25.8g of methyl acrylate dropwise, after the addition, it rises to 40 ℃, continue stirring for 3h, add 21.8g of Boc anhydride, then rise to 25°C, stir at this temperature for 2h, stop the reaction, concentrate to dryness, add 100mL of water, dissolve and extract three times with dichloromethane, and combine the organic phases , the organic phase was washed once with saturated brine, dried over anhydrous sodium sulfate, and concentrated to dryness to obtain 21.2 g of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-propionic acid methyl ester, 3 Yield of -(tert-butoxycarbonyl-methoxycar...

Embodiment 3

[0025] The preparation method of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-propionic acid methyl ester of the present embodiment comprises the following steps: take a dry 250mL three-necked bottle, and add 12.6g of glycine methyl ester salt Add 252mL of methanol, start stirring, add 2.6g of TMSOK and 15.2g of DBU, then slowly add 25.8g of methyl acrylate dropwise, after the addition, raise the reaction to 65°C, continue stirring for 1h, Add 21.8g of Boc anhydride, then raise it to 25°C, stir at this temperature for 2h, stop the reaction, concentrate to dryness, add 100mL of water, dissolve and extract three times with dichloromethane, combine the organic phase, and use saturated brine for the organic phase Washed once, dried with anhydrous sodium sulfate, and concentrated to dryness to obtain 23.5 g of 3-(tert-butoxycarbonyl-methoxycarbonylmethyl-amino)-propionic acid methyl ester, 3-(tert-butoxycarbonyl -Methoxycarbonylmethyl-amino)-propionic acid methyl ester yield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com