Injection molding machine with heat preservation structure

A technology for injection molding machines and injection devices, which is applied in the field of injection molding machines with thermal insulation structures, which can solve the problems of inconvenient fixing and removing of hoppers, inconvenient movement and fixing, and early cooling of plastics, so as to avoid early solidification and heat The effect of less loss, easy cleaning and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 1-6As shown, the present invention provides an injection molding machine with an insulating structure, including the injection molding machine body 1, the top end of the injection molding machine body 1 fixedly connected to the injection device 11, the left side of the injection device 11 fixedly connected to the bucket 2, the bucket 2 The left side of the injection mold 3 is fixed to the left, and the top portion of the injection device 11 is fixedly coupled to the hopper fixing mechanism 4, and the top of the hopper fixing mechanism 4 is provided with a hopper 41, and the side surface of the injection molding machine body 1 is provided with a moving mechanism 5, the bucket 2 Including the inner tube 21, the bucket inner tube 21 is fixedly attached to the left side of the injection device 11, and the outer side of the binder 21 is fixedly coupled to the heat conductance plate 22, the outer side of the heat transfer plate 22 is fixedly connected to the outer ...

Embodiment 2

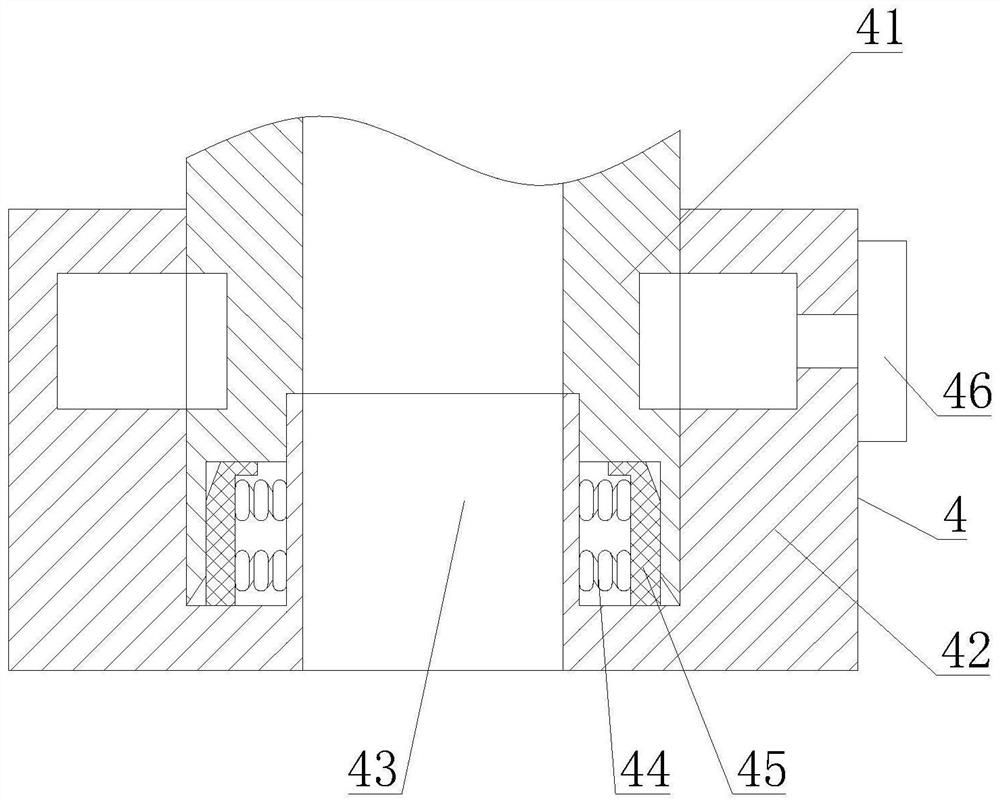

[0041] Such as Figure 1-6 As shown in the basis of the first embodiment, the present invention provides a technical solution: preferably, the hopper fixing mechanism 4 includes a fixing seat 42, and the fixing seat 42 is fixedly attached to the top end of the injection device 11, and the inside of the fixed seat 42 is provided. The venting tube 43, the side surface of the bladder 43 is fixedly connected to the top tightening spring 44, and the sideways of the top-tighten spring 44 are fixedly connected to the top fasten plate 45, and the central portion of the fixing seat 42 is provided with a tensioning mechanism 46, the tensioning mechanism 46 includes The knob 461, the knob 461 is disposed on the side surface of the mount 42, and the left end of the knob 461 is connected to the drive wheel 462, and the side engagement of the active wheel 462 is connected to the driven wheel 463, the left end fixed connection of the driven wheel 463 has a first screw 464, first The side thread o...

Embodiment 3

[0044] Such as Figure 1-6 As shown in the basis of the first embodiment, the present invention provides a technical solution: preferably, the moving mechanism 5 includes a driving handle 51, the drive handle 51 is disposed on the side of the injection molding machine body 1, and the left end fixed connection of the drive handle 51 is provided. The second screw 52, the second screw 52 is disposed inside the injection molding machine body 1, and the side thread of the second screw 52 is connected to the second slider 53, the bottom end activity of the second slider 53 is connected to the push plate 54, the push plate On both sides of the bottom end of the 54, the support leg 55 is fixed, and the bottom end of the support leg 55 is fixedly connected to the moving wheel 56, and the bottom end of the push plate 54 is fixed to the connecting cushion spring 57, the top of the push plate 54 is a trapezoidal structure, push The top of the plate 54 is opened, and the side activity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com