Overheating deformation ventilation type transformer

A transformer and deformation technology, applied in the field of transformers, can solve the problems of transformer components burnt, dust, water vapor blocking, poor heat dissipation, etc., and achieve the effect of expanding the ventilation area and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

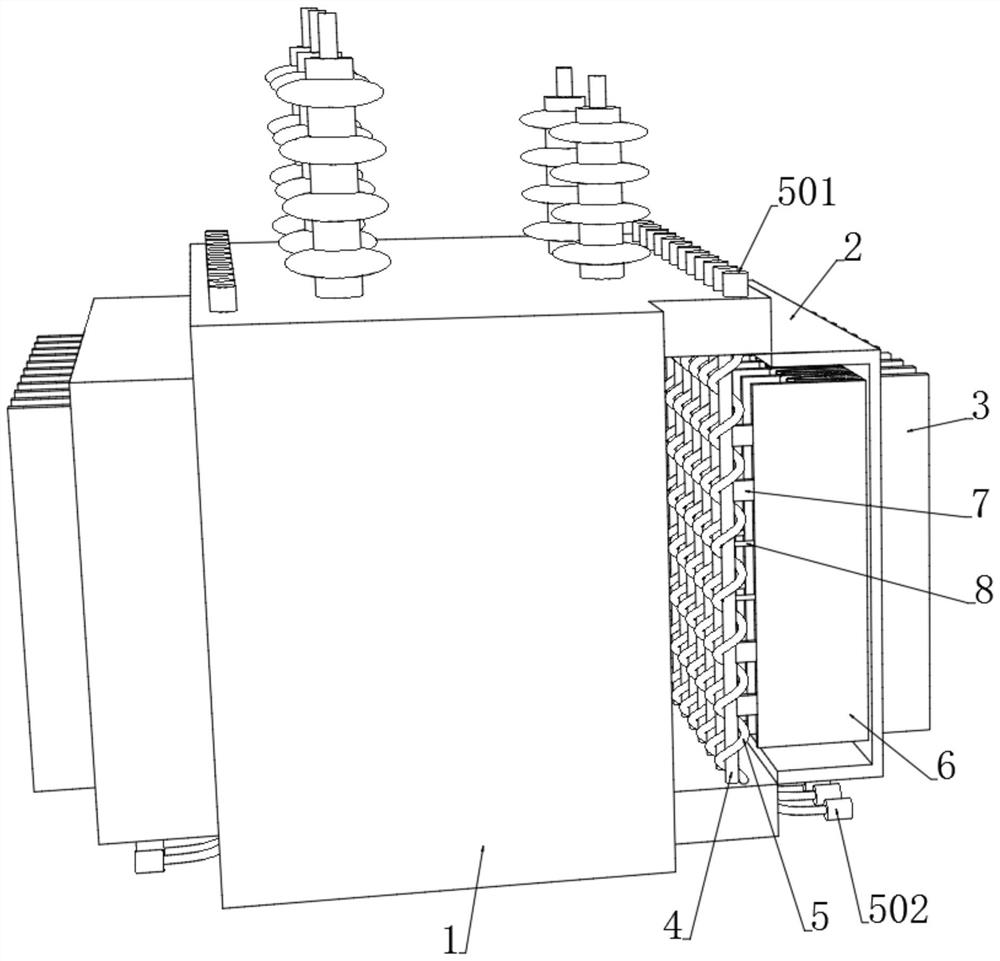

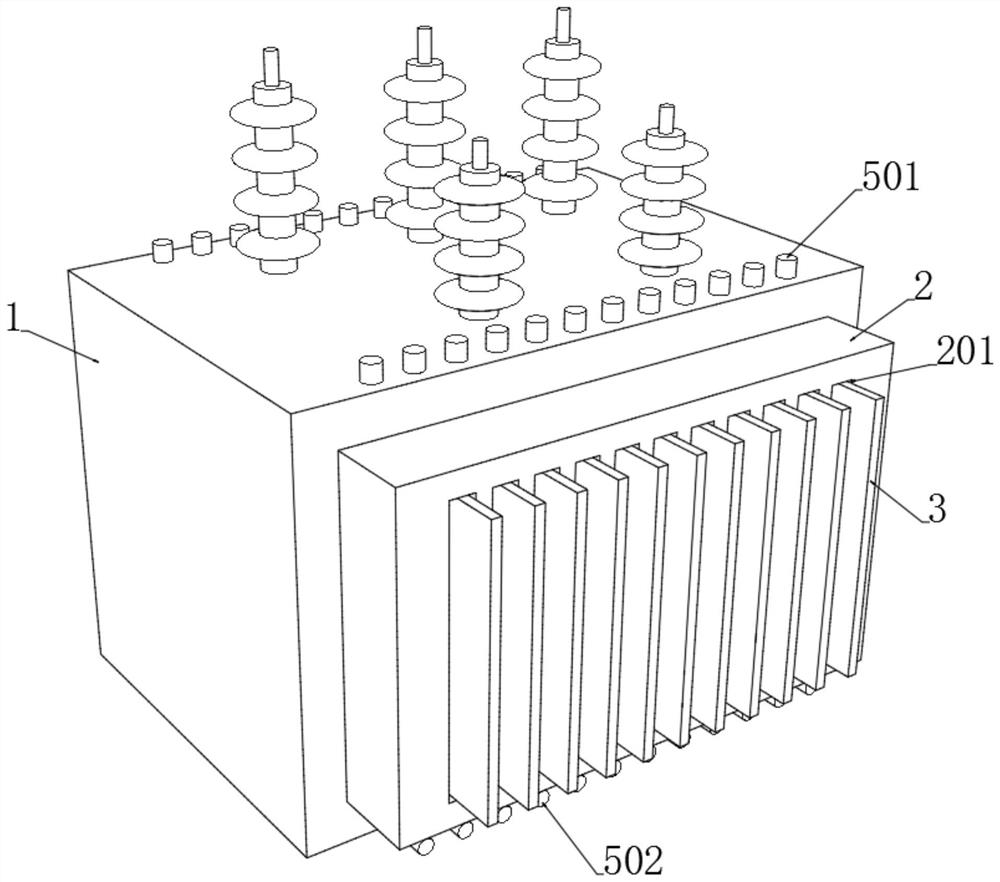

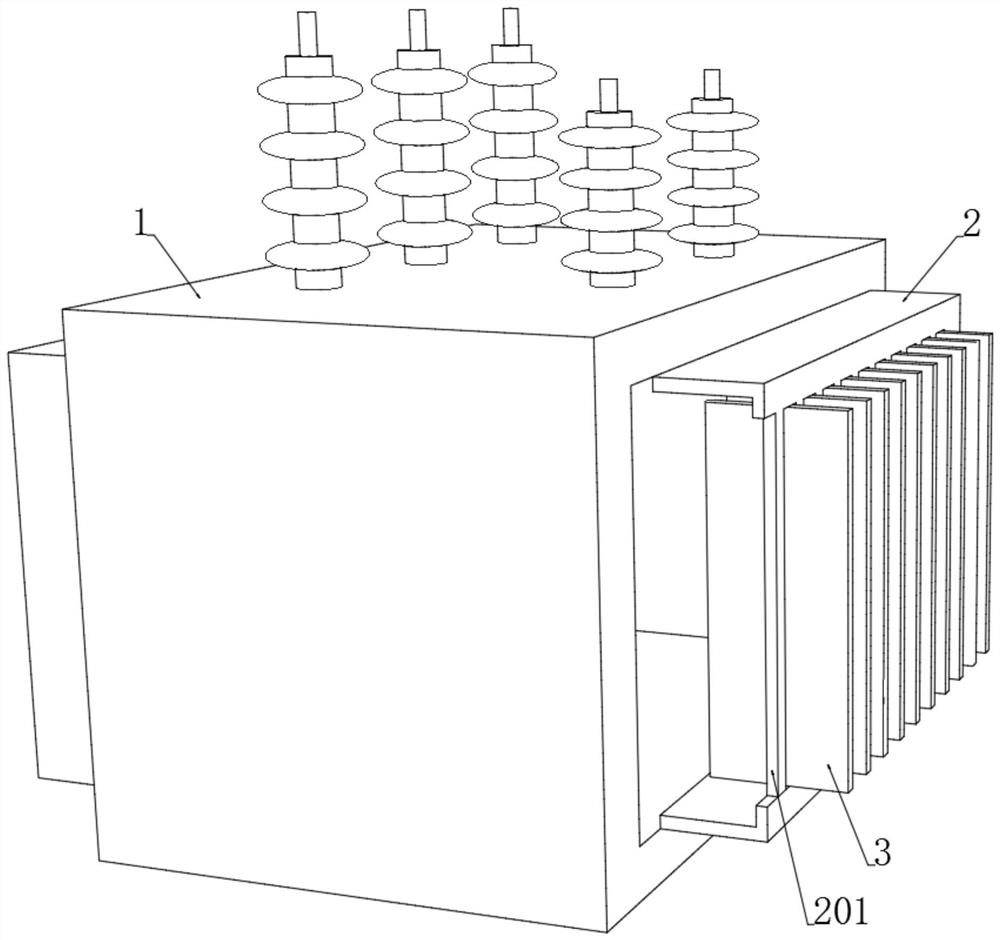

[0044] see Figure 1-3 , an overheating deformation ventilated transformer, comprising a transformer body 1, the left and right ends of the transformer body 1 are equipped with a heat dissipation shell 2 connected to the inside, and a plurality of heat dissipation chambers 201 are opened on the outer end wall of the heat dissipation shell 2, each heat dissipation chamber 201 is equipped with cooling fins 3 that run through the inside and outside. The upper and lower ends of the cooling fins 3 are respectively connected with the upper and lower inner walls of the cooling cavity 201, and the cooling fins 3 and the left and right walls of the cooling cavity 201 form ventilation gaps. The inner walls of the cooling shell 2 are fixedly connected. A heat conduction plate 6 spaced apart from a plurality of heat dissipation cavities 201, two adjacent heat conduction plates 6 are symmetrically arranged on the left and right sides of the heat sink 3, please refer to Figure 7-8 , the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com