Method for preparing biodiesel from rhodosporidium toruloides

A technology of Rhodosporidium toruloides and biodiesel, which is applied in the field of biodiesel preparation, can solve the problems such as difficulty in breaking the walls of Rhodosporidium toruloides, complicated transesterification reaction process, environmental pollution of catalysts, etc., and achieves efficient comprehensive utilization. , The effect of reducing the cost of commercial application and solving the difficulty of yeast wall breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

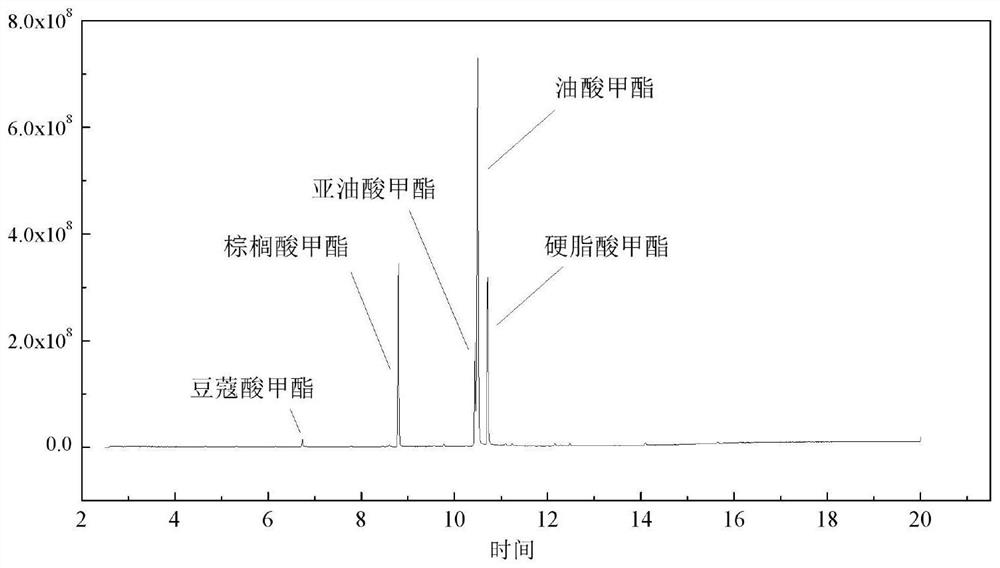

Examples

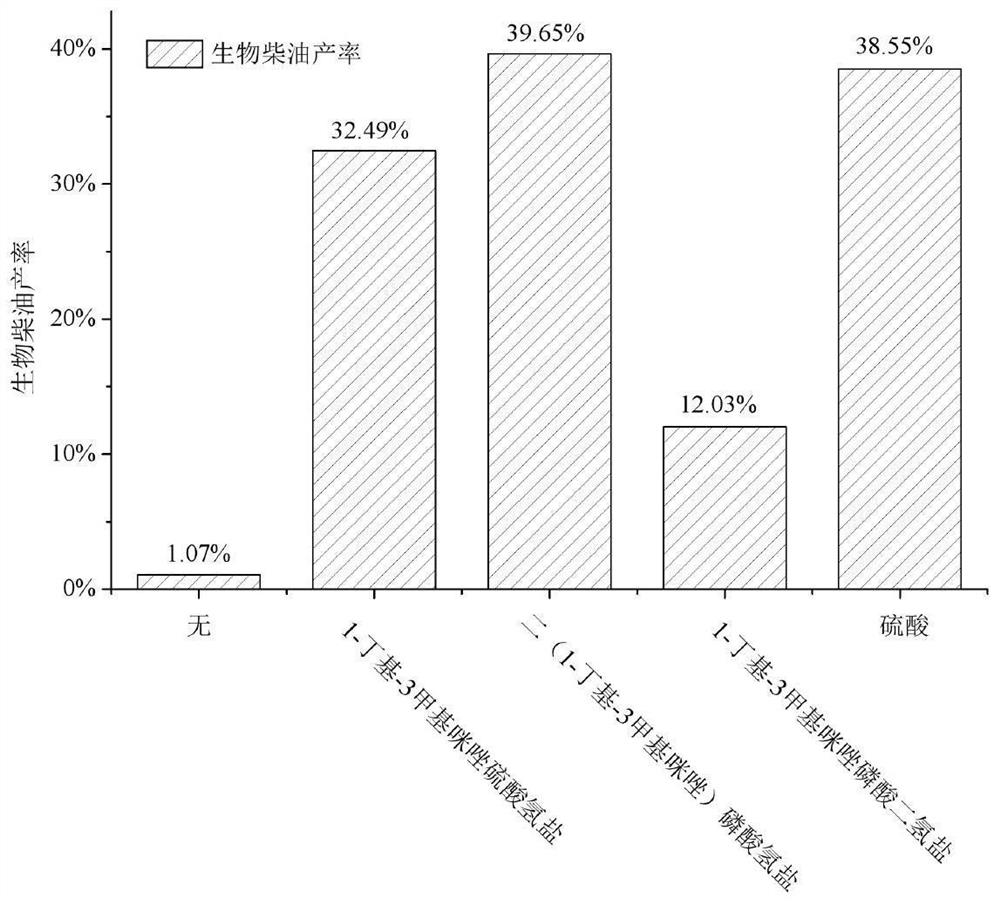

Embodiment 1

[0043] The present embodiment provides a method for preparing biodiesel by Rhodosporidium toruloides, the method specifically comprising the following steps:

[0044] (1): After drying Rhodosporidium toruloides, use a 120-mesh sieve to sieve, and weigh 5g for later use;

[0045] (2): Weigh 40g of methanol and 5g of 1-butyl-3 methylimidazolium bisulfate;

[0046] (3): Put the yeast in step (1), methanol and 1-butyl-3 methylimidazolium bisulfate in step (2) into the reaction kettle, shake slightly to mix the reactants evenly, and cover the reaction Kettle lid to seal the reactor;

[0047] (5): Feed enough N into the reactor 2 , discharge the air in the reactor;

[0048] (6): Heating the reactor, the reaction temperature is 100°C;

[0049] (7): After reaching the reaction temperature, keep the temperature for 60 minutes, that is, the reaction time is 60 minutes;

[0050] (8): After the reaction, cool down to room temperature naturally;

[0051] (9): Open the lid of the reac...

Embodiment 2

[0057] The present embodiment provides a method for preparing biodiesel by Rhodosporidium toruloides, the method specifically comprising the following steps:

[0058] (1): After drying Rhodosporidium toruloides, use a 120-mesh sieve to sieve, and weigh 5g for later use;

[0059] (2): Weigh 40g of methanol and 5g of bis(1-butyl-3methylimidazole) hydrogen phosphate;

[0060] (3): Put the yeast in step (1), methanol and bis(1-butyl-3 methylimidazole) hydrogen phosphate salt in step (2) into the reaction kettle, shake slightly to mix the reactants evenly , cover the lid of the reactor to seal the reactor;

[0061] (5): Feed enough N into the reactor 2 , discharge the air in the reactor;

[0062] (6): Heating the reactor, the reaction temperature is 100°C;

[0063] (7): After reaching the reaction temperature, keep the temperature for 60 minutes, that is, the reaction time is 60 minutes;

[0064] (8): After the reaction, cool down to room temperature naturally;

[0065] (9): ...

Embodiment 3

[0071] The present embodiment provides a method for preparing biodiesel by Rhodosporidium toruloides, the method specifically comprising the following steps:

[0072] (1): After drying Rhodosporidium toruloides, use a 120-mesh sieve to sieve, and weigh 5g for later use;

[0073] (2): Weigh 40g of methanol and 5g of 1-butyl-3-methylimidazolium dihydrogen phosphate;

[0074] (3): Put the yeast in step (1), methanol and 1-butyl-3 methylimidazole dihydrogen phosphate in the reaction kettle, shake slightly to mix the reactants evenly, and cover Reactor lid to seal the reactor;

[0075] (5): Feed enough N into the reactor 2 , discharge the air in the reactor;

[0076] (6): Heating the reactor, the reaction temperature is 100°C;

[0077] (7): After reaching the reaction temperature, keep the temperature for 60 minutes, that is, the reaction time is 60 minutes;

[0078] (8): After the reaction, cool down to room temperature naturally;

[0079] (9): Open the lid of the reaction k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com