Preparation method of biodegradable water-resistant shield tail sealing grease

A shield tail seal and biodegradable technology, which is applied in lubricating compositions, thickeners, petroleum industry, etc., can solve the problems of low biodegradation rate of shield tail seal grease, improve waterproof effect, improve degradation effect, and enhance sealing The effect of sex and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

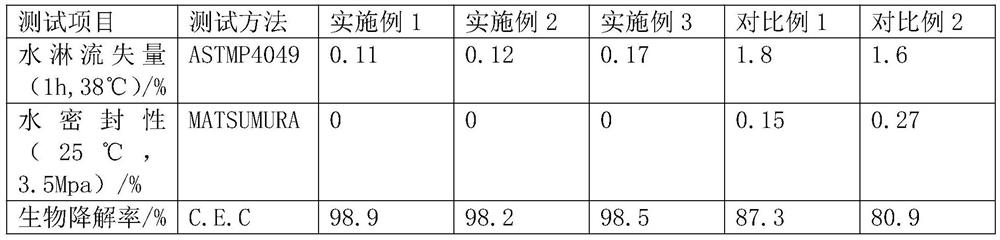

Examples

Embodiment 1

[0023] A biodegradable water-resistant shield tail sealant, mainly composed of the following raw materials in parts by weight: 125 parts of lubricating grease, 28 parts of solid additives, 3 parts of antioxidant, 6 parts of rust inhibitor, 1.75 parts of oily agent, structure 4 parts of stabilizer, 2 parts of multi-effect additive.

[0024] The lubricating grease is mainly composed of base fat, radish seed extract and sala seed extract in a weight ratio of 6:2:1, wherein the base fat is a composite aluminum-based grease; the solid additive is asbestos powder and plant fiber; the solid The particle size range of the additive is 0.5-50 μm, the solid additive with a particle size of 0.5-10 μm accounts for 15% of the total weight of the solid additive, and the solid additive with a particle size of 10-20 μm accounts for 35% of the total weight of the solid additive The solid additive with a particle size of 20-40 μm accounts for 25% of the total weight of the solid additive, and th...

Embodiment 2

[0032] A biodegradable water-resistant shield tail sealant, mainly composed of the following raw materials in parts by weight: 100 parts of lubricating grease, 10 parts of solid additives, 2 parts of antioxidant, 2 parts of antirust agent, 0.5 part of oily agent, structure 2 parts of stabilizer, 1 part of multi-effect additive.

[0033]The lubricating grease is mainly composed of base grease, radish seed extract and sala seed extract in a weight ratio of 5:3:1, wherein the base grease is a composite titanium-based grease. The solid additive is mixed with asbestos powder, calcium carbonate and composite fiber. The particle size range of the solid additive is 0.5-50 μm. Among the solid additives, solid additives with a particle size of 0.5-10 μm account for 10% of the total weight of the solid additives, solid additives with a particle size of 10-20 μm account for 20% of the total weight of the solid additives, and solid additives with a particle size of 20-40 μm It accounts f...

Embodiment 3

[0041] A biodegradable water-resistant shield tail sealant, mainly composed of the following raw materials in parts by weight: 150 parts of lubricating grease, 45 parts of solid additives, 5 parts of antioxidant, 8 parts of antirust agent, 2 parts of oily agent, structure 5 parts of stabilizer, 3 parts of multi-effect additive.

[0042] The lubricating grease is mainly composed of base fat, radish seed extract and sala seed extract in a weight ratio of 7:2:2, wherein the base fat is a mixture of calcium-based fat and sodium-based fat. The solid additive is formed by mixing calcium carbonate and plant fiber. The particle size range of the solid additive is 0.5-50 μm. Among the solid additives, solid additives with a particle size of 0.5-10 μm account for 20% of the total weight of the solid additives, solid additives with a particle size of 10-20 μm account for 40% of the total weight of the solid additives, and solid additives with a particle size of 20-40 μm Accounting for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com