Implanted instrument nano coating as well as preparation method and application thereof

A nano-coating and device technology, applied in the fields of polyphenol surface functionalized nanoparticles, implanted device nano-coating and its preparation, can solve problems such as premature water reaction, achieve broad application value, and promote osteogenic differentiation , The effect of good sterilization ability in the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In a fourth aspect of the present disclosure, a method for preparing a nano-coating for an implanted device is provided, comprising: soaking the implanted device in CaO 2 -TA nanoparticle solution, followed by adding metal ion solution for reaction.

[0039] Preferably, the solution is absolute ethanol, metal ions are added after stirring, and the reaction time is 10-14 hours; the stirring time is 8-16 hours, preferably 12 hours;

[0040] Preferably, the metal ion solution is a copper ion solution, preferably CuCl 2 ; The concentration of the metal ion solution is 0.02mol / L-0.03mol / L, the CaO 2-The concentration of the TA nanoparticle solution is 0.03mol / L-0.04mol / L.

[0041] Preferably, the preparation method also includes the process of taking out the implanted device after the reaction is completed, washing and drying; further, the number of ethanol cleaning is 2 to 5 times, preferably 3 times;

[0042] Preferably, the implanted device needs to be purified before ...

Embodiment 1

[0046] Example 1: Synthesis of Polyphenol Surface Functionalized Nanoparticles

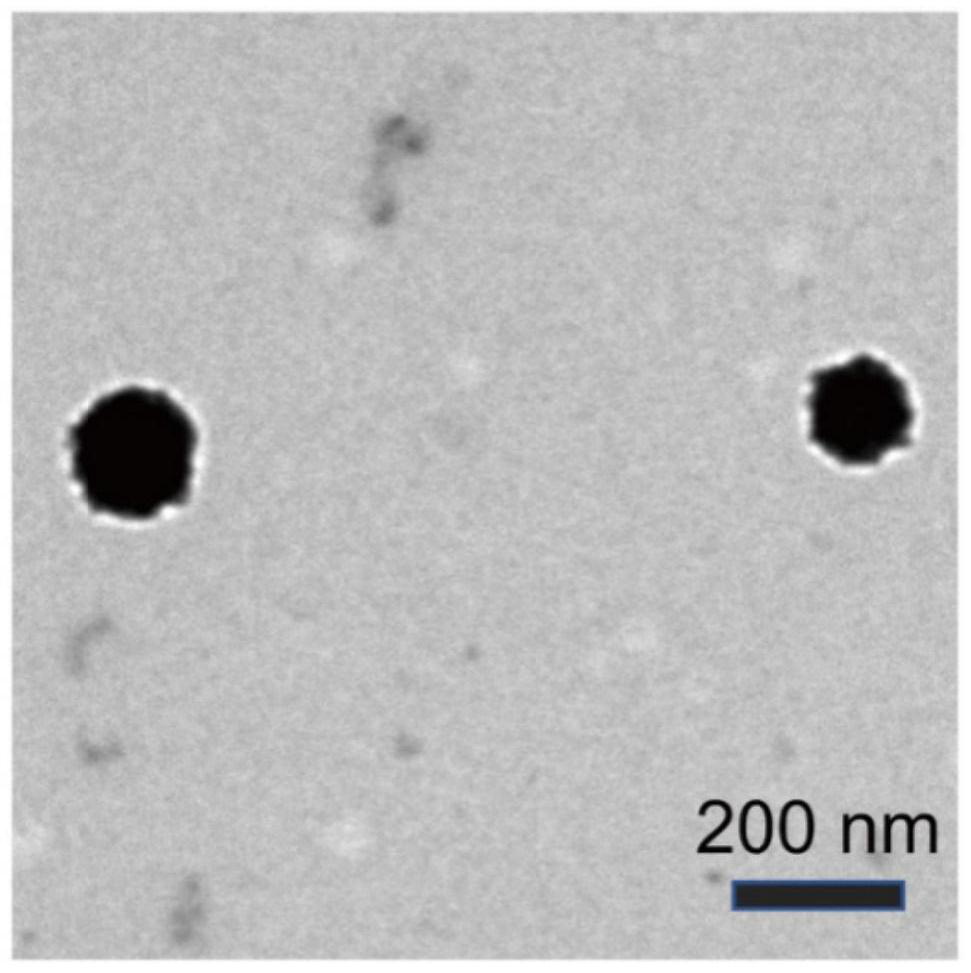

[0047] Dissolve 0.1g CaCl2 and 0.35g PVP in 15mL absolute ethanol by ultrasonication, add 1mL NH 4 OH (0.8M), and add 0.2mL H at a rate of 0.05mL / min with a syringe pump 2 o 2 (1M) solution, stirred for 10 minutes to obtain a light blue milky white solution. Subsequently, 10 μL of TA solution (24 mM) was added to the above dispersion system. The obtained polyphenol surface-functionalized nanoparticles were collected by centrifugation (10000 rpm×5 min), and washed 3 times with absolute ethanol. The prepared polyphenol surface-functionalized nanoparticles were stored at 4°C. The morphology of polyphenol surface-functionalized nanoparticles was examined by TEM, as figure 1 As shown, it can be seen that the prepared nanoparticles are regular in shape, spherical in shape, and the particle size is about 200nm.

Embodiment 2

[0048] Embodiment 2: the synthesis of nanocoating of implant device

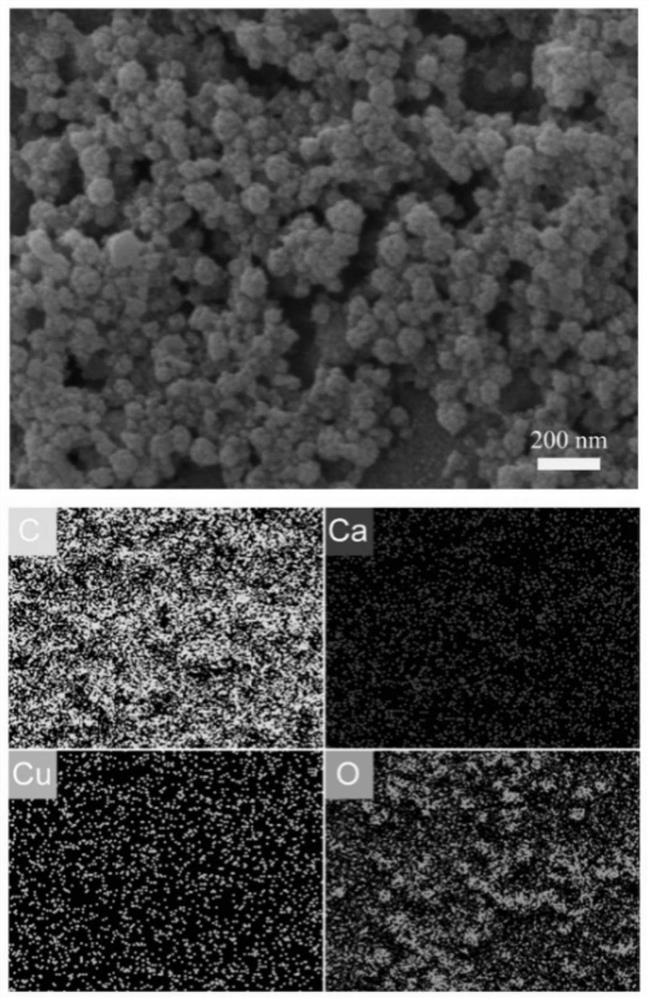

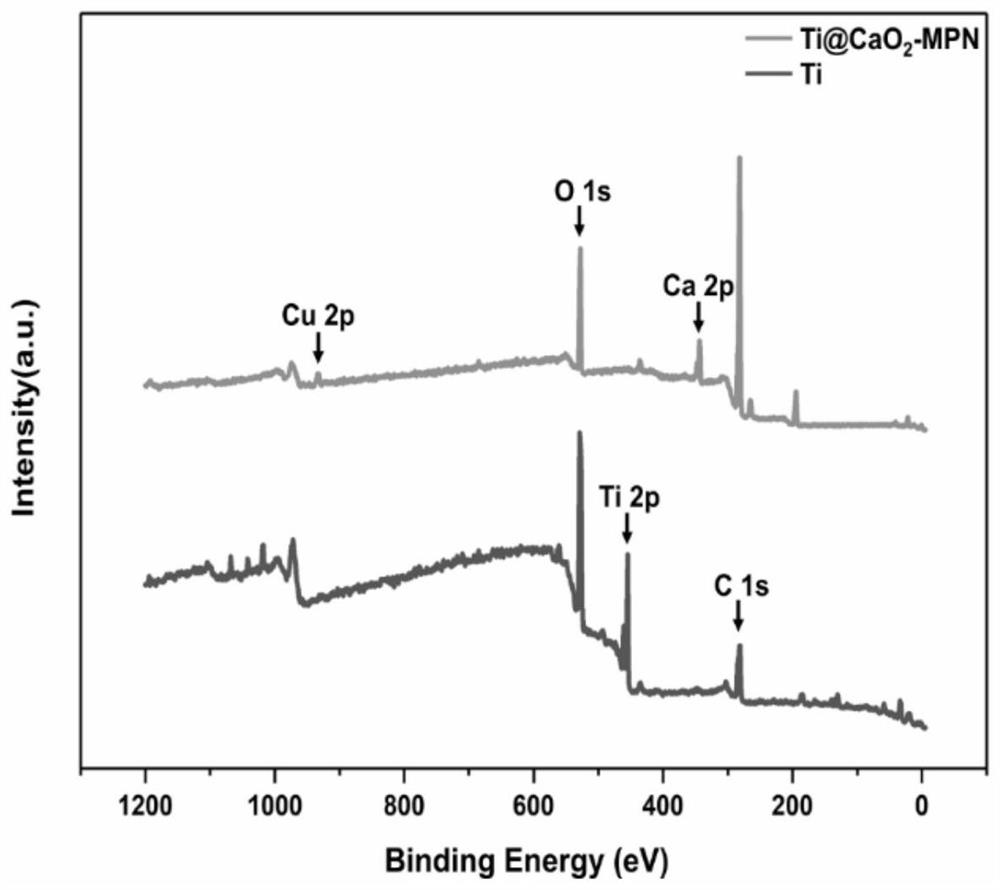

[0049] Firstly, titanium sheets (Ti, Φ10×2mm) and titanium screws (Ti, Φ2×6mm) purchased from Jiangsu Bayers Company were passed through acetone (≥99.5%), ethylene glycol (≥99.5%), and ultrapure water in sequence. Wash for 15 minutes under the action of ultrasound. Then, the purified titanium sheet and titanium screw were treated with CaO at a concentration of 35 mM 2 -Soak TA nanoparticles in ethanol solution, and add Cu at a concentration of 24mM 2+ The metal polyphenol network MPN coating (MPN@Ti) was prepared by stirring for 12 hours, washed with ethanol three times, and dried in an oven for later use. The surface morphology and surface element distribution of MPN@Ti were obtained by SEM ( figure 2 ), the element change of MPN@Ti and Ti was analyzed by XPS ( image 3 ).

[0050] from figure 2 and image 3 It can be seen that the prepared MPN@Ti coating has a uniformly distributed morphology stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com