Low-deformation easy-to-form reinforced nitrogen flame-retardant PA6/PA66 and preparation method thereof

A nitrogen-based flame retardant and PA66 technology, which is applied in the field of low-deformation and easy-to-form reinforced nitrogen-based flame retardant PA6/PA66 and its preparation, can solve the problems of reducing material fluidity, increasing material cost, poor rubber area, etc. Effects of dimensional stability, reduced assembly clearance, high flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

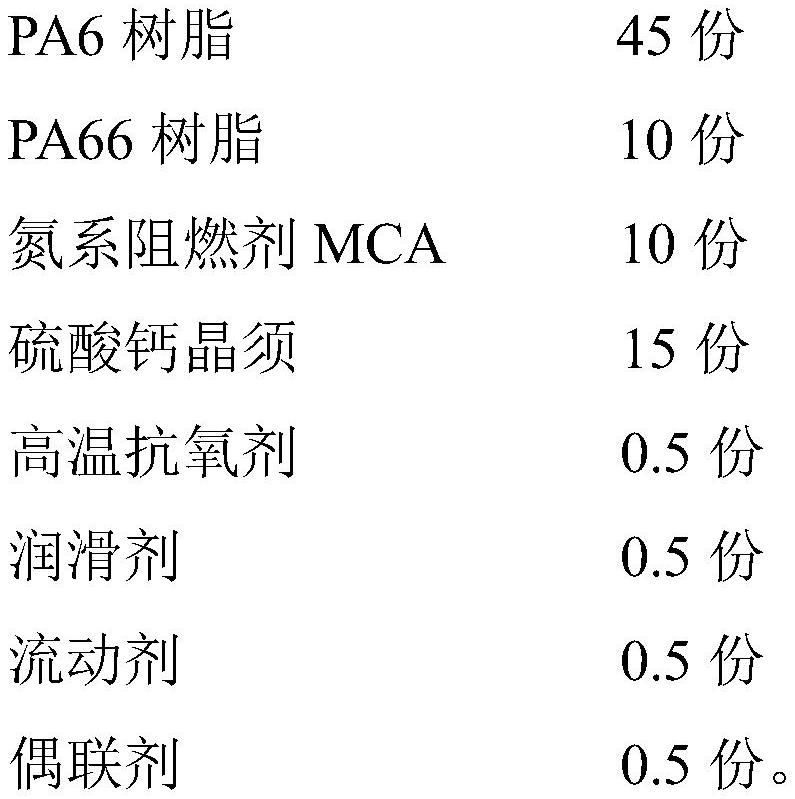

[0030] A low-deformation and easy-to-form reinforced nitrogen-based flame-retardant PA6 / PA66, including the following raw materials:

[0031]

[0032] Among them, the viscosity of PA6 resin is 2.2-2.6Pa.S. The viscosity of PA66 resin is 2.4-2.8Pa.S. The antioxidant is a mixture of antioxidant 245 and antioxidant 168 in a weight ratio of 1:1. The lubricant is N,N'-ethylene bisstearamide. The coupling agent is γ-aminopropyltriethoxysilane. The nucleating agent is BRUGGOLEN P22. The flow agent is BRUGGOLEN M1420.

[0033] A method for preparing low-deformation and easy-to-form reinforced nitrogen-based flame-retardant PA6 / PA66, comprising the following steps:

[0034] (1) take each raw material according to parts by weight;

[0035] (2) each raw material after weighing is mixed in medium-speed mixer for 3-7min, obtains mixed material;

[0036] (3) Add the mixed material obtained in step (2) into a twin-screw extruder, undergo melting reaction, extrude and granulate, whe...

Embodiment 2

[0038] A low-deformation and easy-to-form reinforced nitrogen-based flame-retardant PA6 / PA66, including the following raw materials:

[0039]

[0040]

[0041] Among them, the viscosity of PA6 resin is 2.2-2.6Pa.S. The viscosity of PA66 resin is 2.4-2.8Pa.S. The antioxidant is a mixture of antioxidant 245 and antioxidant 168 in a weight ratio of 1:1. The lubricant is N,N'-ethylene bisstearamide. The coupling agent is γ-aminopropyltriethoxysilane. The nucleating agent is BRUGGOLEN P22. The flow agent is BRUGGOLEN M1420.

[0042] A method for preparing low-deformation and easy-to-form reinforced nitrogen-based flame-retardant PA6 / PA66, comprising the following steps:

[0043] (1) take each raw material according to parts by weight;

[0044] (2) each raw material after weighing is mixed in medium-speed mixer for 3-7min, obtains mixed material;

[0045] (3) Add the mixed material obtained in step (2) into a twin-screw extruder, undergo melting reaction, extrude and gr...

Embodiment 3

[0047] A low-deformation and easy-to-form reinforced nitrogen-based flame-retardant PA6 / PA66, including the following raw materials:

[0048]

[0049]

[0050] Among them, the viscosity of PA6 resin is 2.2-2.6Pa.S. The viscosity of PA66 resin is 2.4-2.8Pa.S. The antioxidant is a mixture of antioxidant 245 and antioxidant 168 in a weight ratio of 1:1. The lubricant is N,N'-ethylene bisstearamide. The coupling agent is γ-aminopropyltriethoxysilane. The nucleating agent is BRUGGOLEN P22. The flow agent is BRUGGOLEN M1420.

[0051] A method for preparing low-deformation and easy-to-form reinforced nitrogen-based flame-retardant PA6 / PA66, comprising the following steps:

[0052] (1) take each raw material according to parts by weight;

[0053] (2) each raw material after weighing is mixed in medium-speed mixer for 3-7min, obtains mixed material;

[0054] (3) Add the mixed material obtained in step (2) into a twin-screw extruder, undergo melting reaction, extrude and gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com