Sizing material for spiral spring supporting seat, preparation method of sizing material and automobile spiral spring supporting seat

A technology of coil springs and support seats, which is applied in the field of coil spring support seats and rubber materials for coil spring support seats. It can solve the problems of reduced vehicle comfort, increased product stiffness, and reduced shock absorption performance, and achieves improved damping and weather resistance. Good resistance, small shrinkage, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

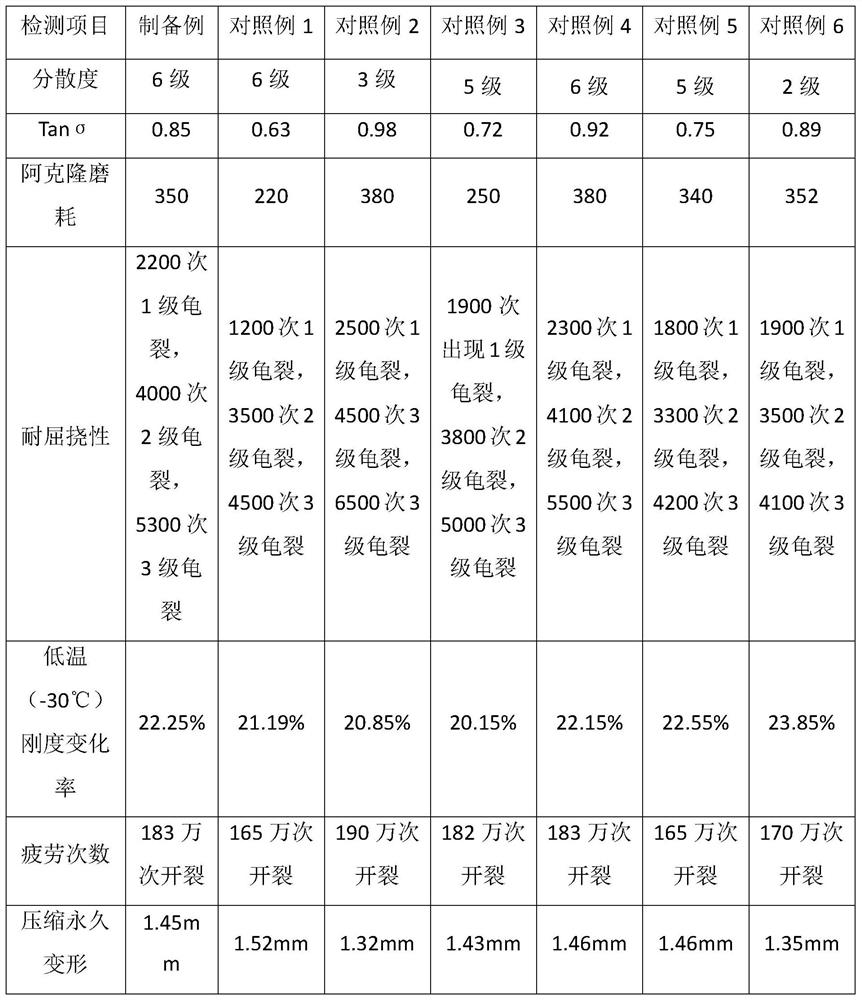

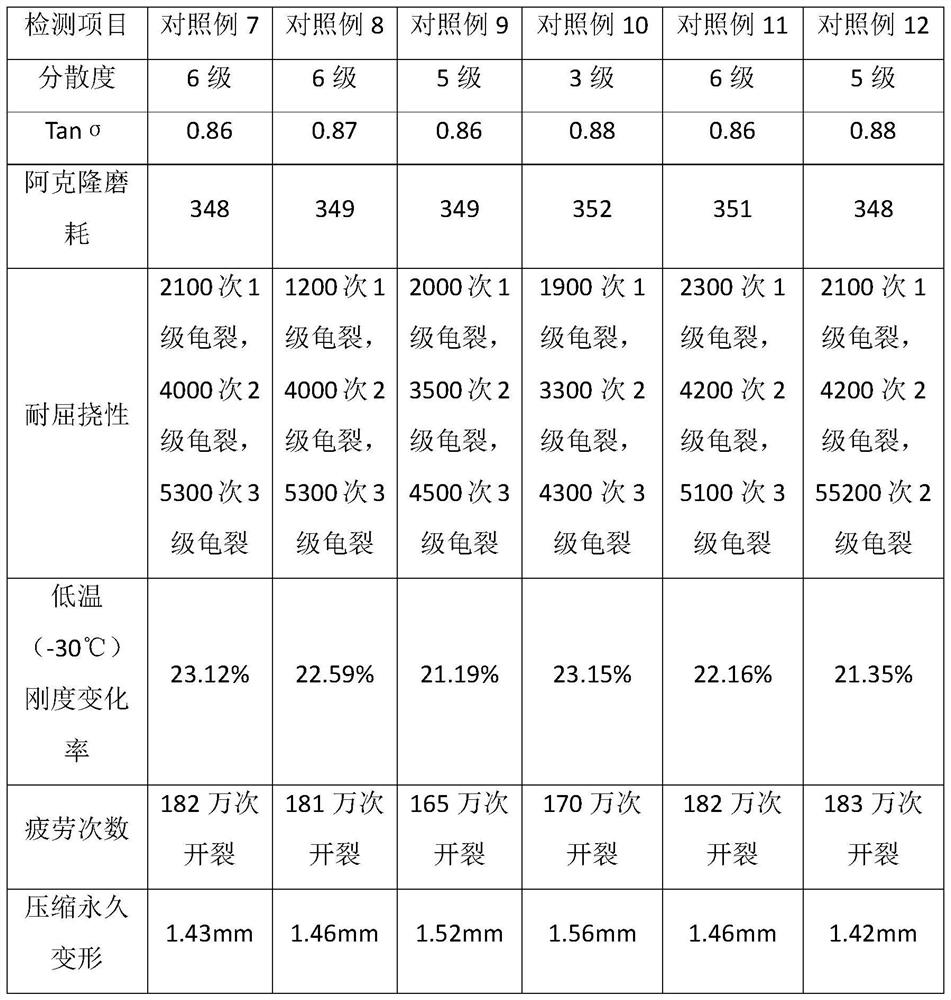

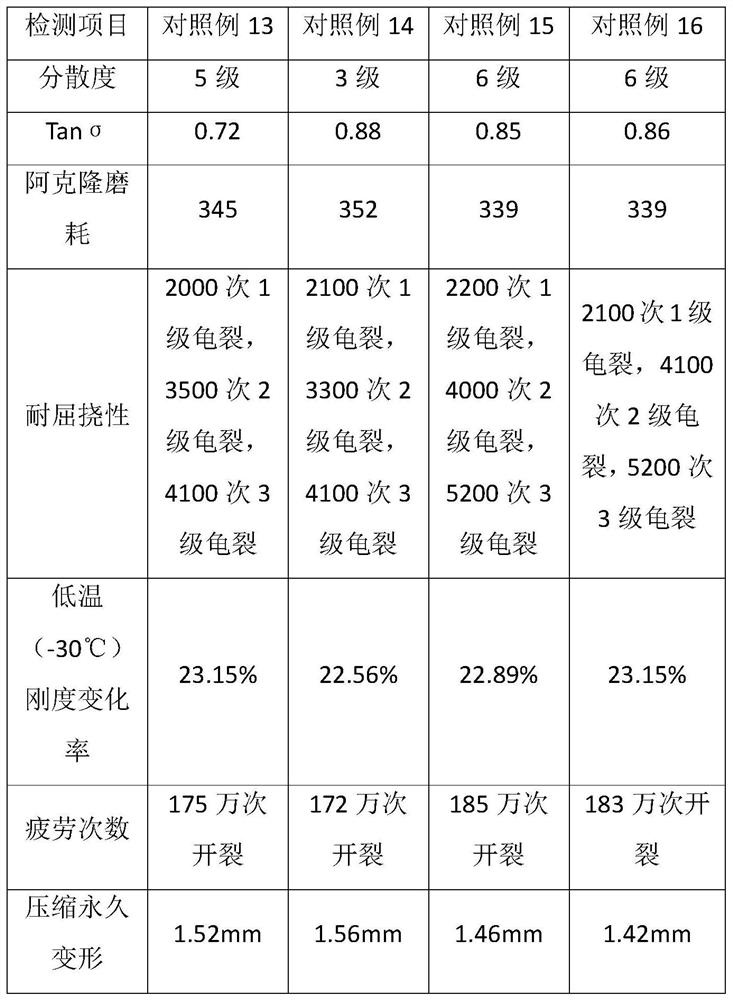

Examples

Embodiment 1

[0034] This embodiment relates to a rubber material for a helical spring support seat. In terms of overall design, the rubber material for a helical spring support seat is made of the following components by weight: butyl rubber: 60-80 parts, cis-1 , 4-polybutadiene rubber: 20-40 parts, zinc oxide: 3-5 parts, stearic acid: 1-2 parts, Sumilink100: 3-6 parts, thermoisorubber: 5-15 parts, carbon black N330 : 20-30 parts, white carbon black 7000GR: 10-15 parts, POLYVEST: 1-1.5 parts, paraffin oil: 10-20 parts, antioxidant: 5-8 parts, sulfur: 0.75-0.85 parts, accelerator: 3.70 -4.35 parts.

[0035] Among them, in the composition of the above components, butyl rubber and cis-1,4-polybutadiene rubber used in combination constitute the raw rubber system of this embodiment. Butyl rubber has low elasticity, good vibration absorption performance and weather resistance, and has the characteristics of high damping and high wear resistance, which can improve the damping, weather resistance...

preparation example

[0060] In this preparation example, the rubber material for the coil spring support seat is made of the following components in parts by weight: star branched butyl rubber: 70 parts, cis-1,4-polybutadiene rubber: 30 parts , Thermal different rubber: 10 parts, Sumilink100: 5 parts, POLYVEST: 1.5 parts, zinc oxide: 5 parts, stearic acid: 1 part, carbon black N330: 20 parts, white carbon black 7000GR: 15 parts, high viscosity paraffin oil : 15 parts, anti-aging agent TMQ: 2 parts, anti-aging agent 4020: 3 parts, anti-aging agent MB: 3 parts, sulfur: 0.8 parts, dimethyldiphenylthiuram disulfide: 1.5 parts, N-oxygen Ethylenethiocarbamoyl-N'-oxydiethylenesulfenamide: 1.65 parts, 2-mercaptobenzothiazole zinc salt: 1.2 parts.

[0061] For the preparation method of the rubber material for the helical spring support seat in this preparation example, refer to the above preparation method.

Embodiment 2

[0128] This embodiment relates to a car coil spring support, which is made of the rubber material for the coil spring support seat in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com