Special high-strength acrylic plate for aquarium and preparation method thereof

An acrylic board and lower acrylic board technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of inability to change the strength, affecting tourists' viewing, dirty acrylic boards, etc., and achieve excellent light transmission performance and physical performance , The effect of improving thermal oxidation stability and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

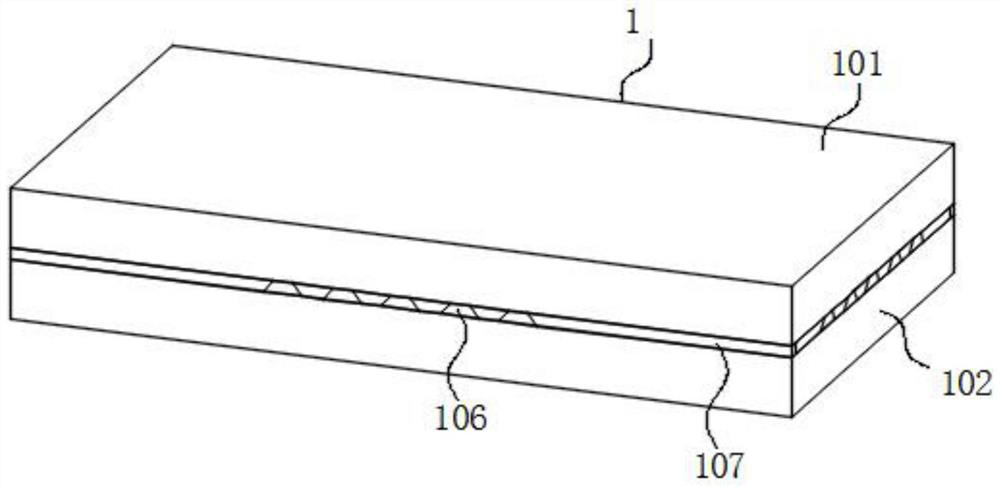

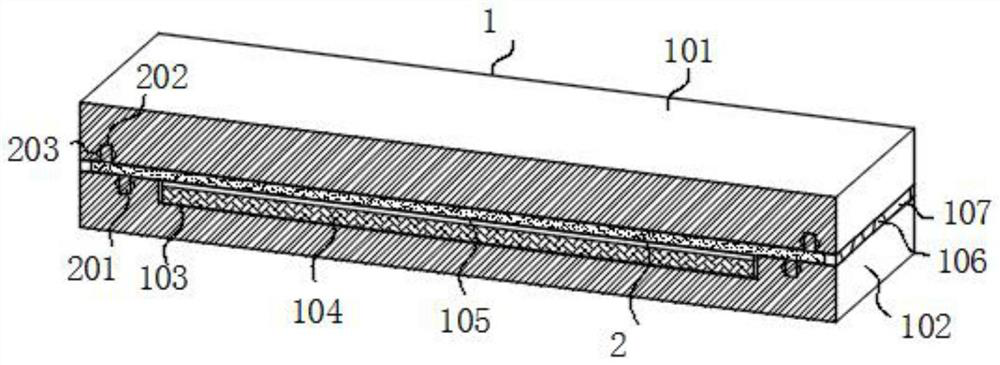

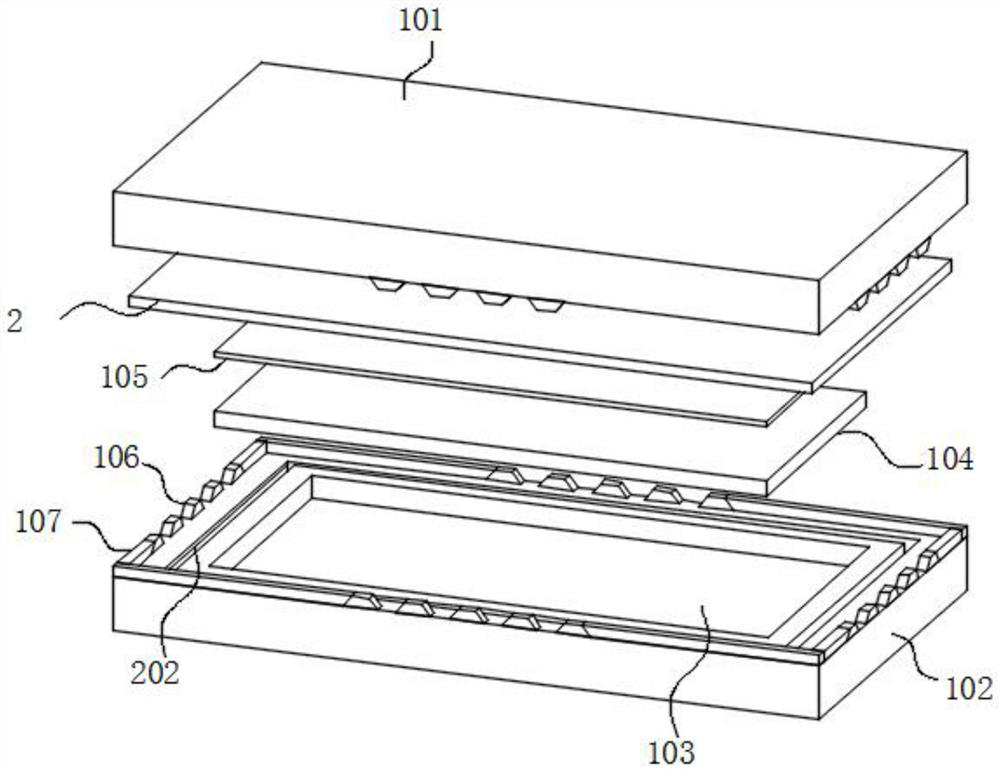

[0031] The invention provides a special high-strength acrylic board for the aquarium, such as Figure 1-3 As shown, it includes an acrylic board body 1, the acrylic board body 1 includes an upper acrylic board 101 and a lower acrylic board 102, and an adhesive layer 2 is arranged between the upper acrylic board 101 and the lower acrylic board 102;

[0032] The surface of the lower acrylic plate 102 is provided with a painting groove 103, the depth of the painting groove 103 is equal to the sum of the thickness of the landscape painting layer 104 and the protective layer, and the protective layer is made of transparent UV glue material. A landscape layer 104 is provided, the surface of the landscape layer 104 is provided with a protective layer 105, the top and bottom of the adhesive layer are provided with bonding protrusions 201, and the surfaces of the upper acrylic plate 101 and the lower acrylic plate 102 are provided with There are bonding grooves 202 matching the bonding...

Embodiment 2

[0036] The acrylic plate body 1 is made of transparent high-strength acrylic, and the transparent high-strength acrylic is made of the following raw materials in parts by weight: 75-95 parts of methyl methacrylate, 1-5 parts of crosslinking agent, 1-3 parts of high-temperature initiator part, 0-25 parts of flame retardant, 1-3 parts of low-temperature initiator, 5-10 parts of release agent, and the crosslinking agent is triallyl isocyanurate, triallyl isocyanurate ester, diallyl phthalate, and the release agent is one or more of epoxy resin, petroleum resin, urea-formaldehyde resin, acrylic resin, and the flame retardant Be dimethyl methylphosphonate, its preparation method is as follows:

[0037] Pre-polymerize methyl methacrylate, cross-linking agent and high-temperature initiator, then add flame retardant, low-temperature initiator and mold release agent, stir evenly, and it becomes clear and transparent; the mixed slurry is under the vacuum condition of -0.1MPa Degassing ...

Embodiment 3

[0040] The invention also discloses a method for preparing a special high-strength acrylic plate for aquariums, comprising the following steps:

[0041] S1: Clean the produced upper acrylic plate 101 and lower acrylic plate 102, keep them for later use, and prepare the printing materials required for the landscape layer 104;

[0042] S2: Put the lower acrylic plate 102 on the embossing equipment, and use the imprinting equipment that depicts the pattern that matches the picture layer 104 to emboss the patterned groove 103 on the surface of the lower acrylic plate 102, and during the embossing process The lower acrylic plate 102 is compacted to have a higher strength, and then the prepared printing equipment uses printing materials to print the color required for the pattern into the pattern of the painting groove 103, and the raw materials are dried to prepare a landscape painting layer 104, and then coat the transparent liquid glue on the surface of the landscape layer 104, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com