Composite fungus flavoring agent production equipment

A production equipment and seasoning technology, which is applied in the field of compound fungi seasoning production equipment, can solve problems such as single taste, non-uniform mushroom drying standards, and destruction of umami flavor of fungi, so as to achieve simple use, guarantee of original flavor, The effect of high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

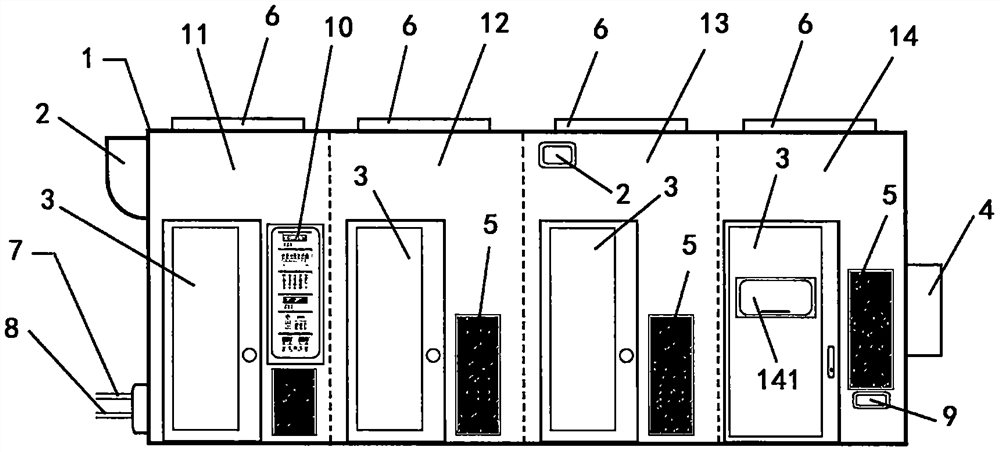

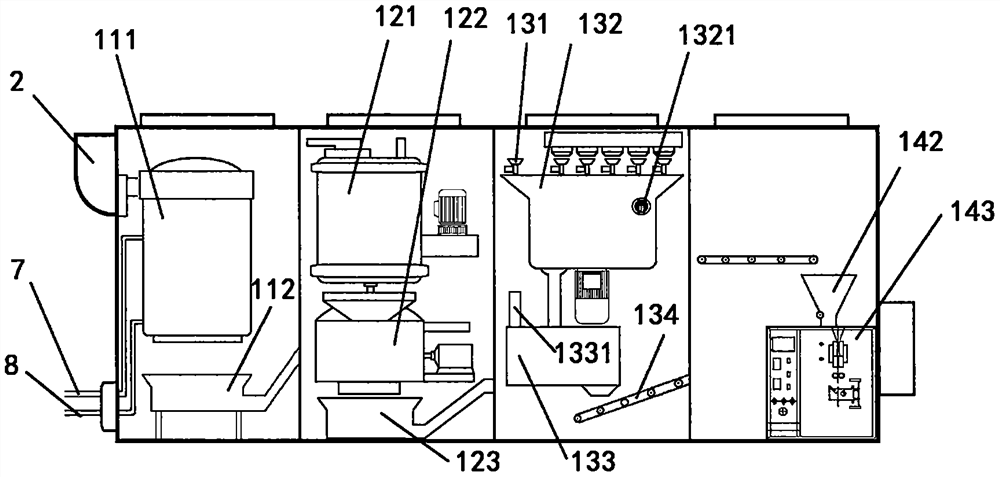

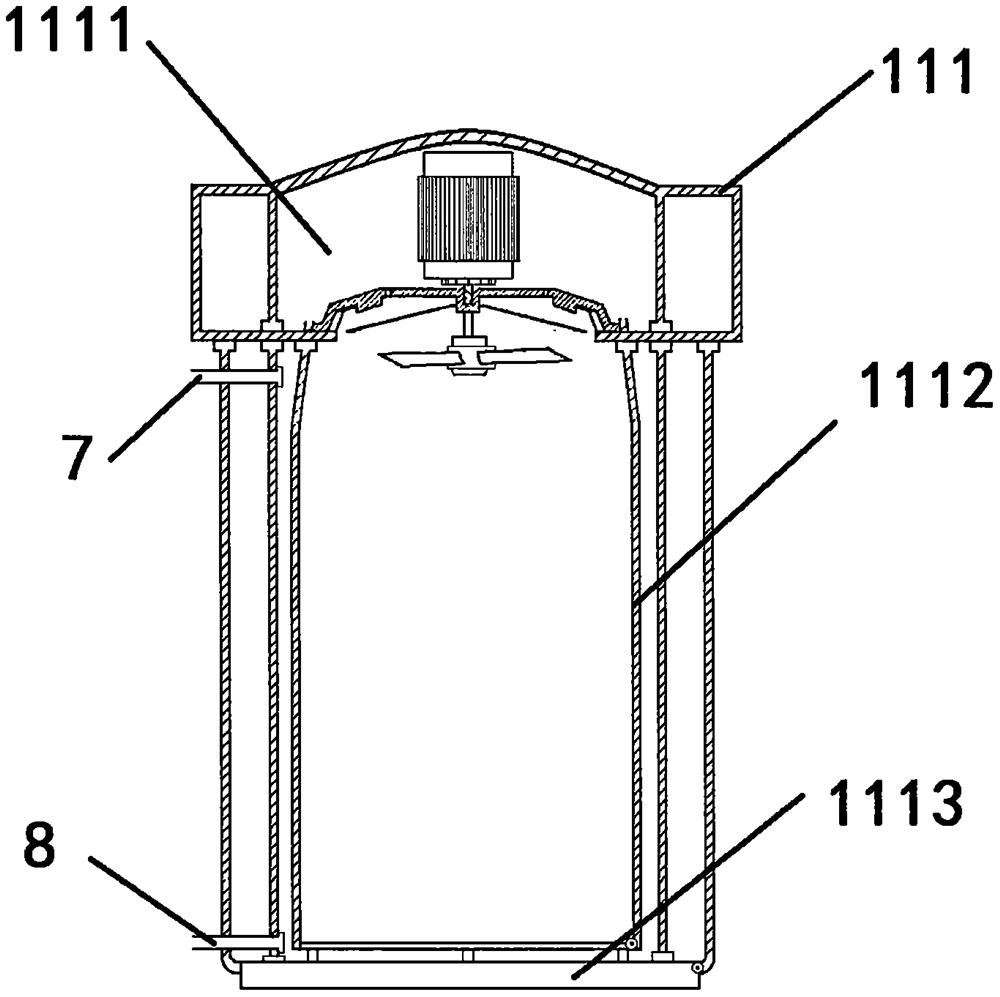

[0030] See the accompanying drawings in the manual figure 1 , the compound fungus seasoning production equipment includes a processing bin (1), a feed inlet (2), a bin door (3), a finished product outlet (4), an air inlet (5), a moisture outlet (6), a water inlet ( 7), drainage pipe (8), waste material port (9), control panel (10); processing chamber (1) is cuboid.

[0031] The processing chamber (1) is divided into 4 parts by partitions, the cleaning part (11), the crushing part (12), the mixing and granulating part (13), and the packaging part (14). The four parts are arranged in sequence from left to right, ensuring Every step of production is separated from each other;

[0032] 4 parts in the processing chamber (1), each part is provided with a chamber door (3), an air inlet (5), a moisture discharge outlet (6), a temperature adjustment device, and an air inlet (5) It is arranged on the side wall of the processing chamber (1), and the moisture outlet (6) is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com