Lithography machine energy detection device and detection method

A technology of energy detection and lithography machine, which is applied in the direction of using electric radiation detectors for photometry, etc., can solve the problems of regional non-compliance, substrate property loss, pass rate attenuation, etc., to improve exposure accuracy, increase energy range, Effect of Preventing Measurement Errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

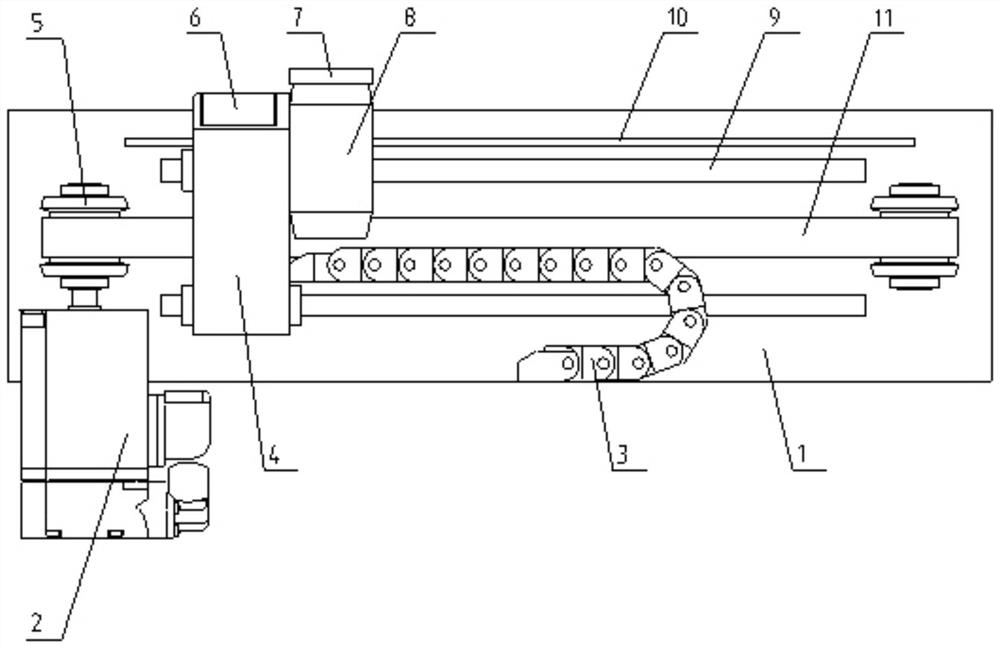

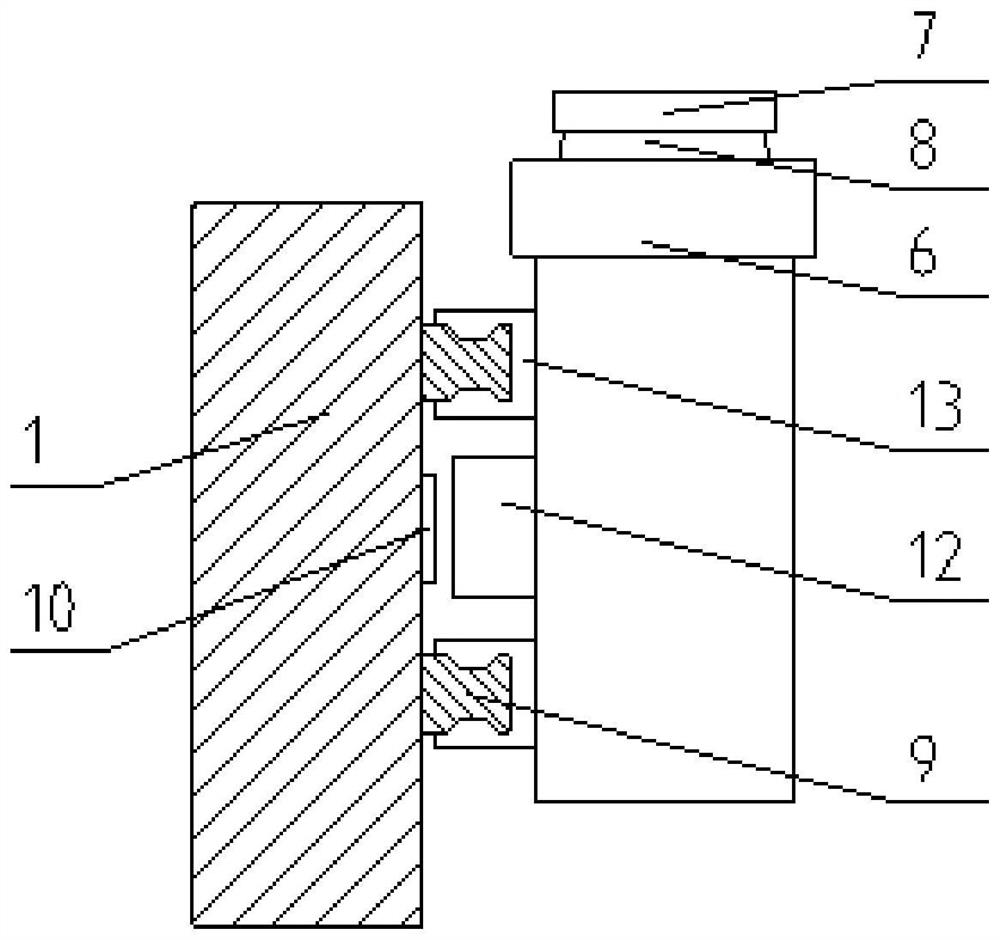

[0031] see figure 1 and figure 2 , the lithography machine energy detection device proposed by the present invention includes a mounting plate 1, the mounting plate 1 is fixedly installed in the movement mechanism of the lithography machine, and two guide rails 9 are fixedly arranged on the front end of the mounting plate 1 in a transverse direction, so that One side of the mounting plate is fixedly provided with a servo motor 2, the servo motor 2 drives the mounting seat 4 through the synchronous wheel 5 and the synchronous belt 11, and the mounting seat 4 is slidably arranged between two guide rails through the slider 13. The servo motor 2 is the engine that controls the operation of the mechanical components in the servo system. It is an auxiliary motor indirect transmission device that can control the speed and the position accuracy is very accurate. It can convert the voltage signal into torque and speed to drive the mounting seat 4.

[0032] A CCD 8 is fixedly installe...

Embodiment 2

[0040] In this embodiment, the present invention also proposes a method for detecting the energy of a lithography machine, comprising the following steps:

[0041] Step 1: Divide the light-emitting area of the lithography machine into N equal parts according to the field of view of the CCD, and the number of CCD-sensitive pixels is M when the light-emitting area of each part of the lithography machine is projected separately;

[0042] Step 2: Move the CCD to the light-emitting area of the lithography machine by controlling the movement mechanism of the lithography machine and the servo motor that drives the mounting seat to slide, respectively measure the gray value of each pixel in each area, and calculate the average to obtain Ambient light gray value B;

[0043] Step 3: Map separately the light-emitting areas of the N lithography machines after equal division in turn, and use the CCD to measure the gray value of each pixel in the area, and obtain all the light-emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com